Used UNIVERSAL GSM I #9085996 for sale

URL successfully copied!

Tap to zoom

ID: 9085996

Pick and place machine

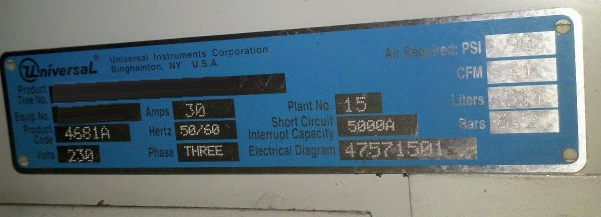

Specifications:

230V, 30 Amps, 60Hz, 3 Phase

80 PSI.

UNIVERSAL GSM I is a pc board assembly and manufacturing equipment designed for high-end circuit board production. The system is capable of producing single and double-sided circuit boards up to extra-large sizes, and offers very precise and consistent quality assurance. The machine consists of an automatic conveyor-belt, a pick-and-place unit, and an image-centric inspection machine. The conveyor-belt is designed to move components from one station to another in a safe and accurate manner. The pick-and-place tool automatically aligns the components onto the board precisely, while the image-centric inspection asset uses an integrated camera and light source to clearly identify any misplaced components. The model revolutionizes the traditional manual manufacturing process by significantly improving overall quality and productivity. It boasts a number of features over manual printed circuit board (PCB) production systems, including reduced setup time, consistent accuracy, and highly reliable quality control. Additionally, setup is entirely parameterized, so users can quickly reproduce a board layout with the same exact specifications and conditions. GSM I also offers advanced electrical testing capabilities, allowing users to check for electrical shorts, opens, cross-connects, and shorts to ground. It can also detect and localize problems associated with pins, component placement, and component tolerances. The electrical test capability also enables quality assurance testing for boards with very high component counts. The platform also includes a Part Tracking feature, allowing users to track each component in real-time. Other features of UNIVERSAL GSM I include detailed build status reports, improved board recognition, and 100% traceability. Additionally, the equipment manages a comprehensive library of components to store information such as quantity, component type, manufacturer, supplier, and part reference numbers. This information can be accessed to track down existing or new part orders quickly and easily. GSM I is a comprehensive solution for taking PCB production to the next level. By combining the latest in sorting, placement, and inspection technology, it offers an optimized and efficient platform for PCB production. Features such as quick setup, electrical testing, accurate traceability, and detailed build status reports make it an ideal choice for manufacturers looking to reduce costs and streamline production.

There are no reviews yet