Used UNIVERSAL GSM II #123516 for sale

URL successfully copied!

Tap to zoom

ID: 123516

Vintage: 2000

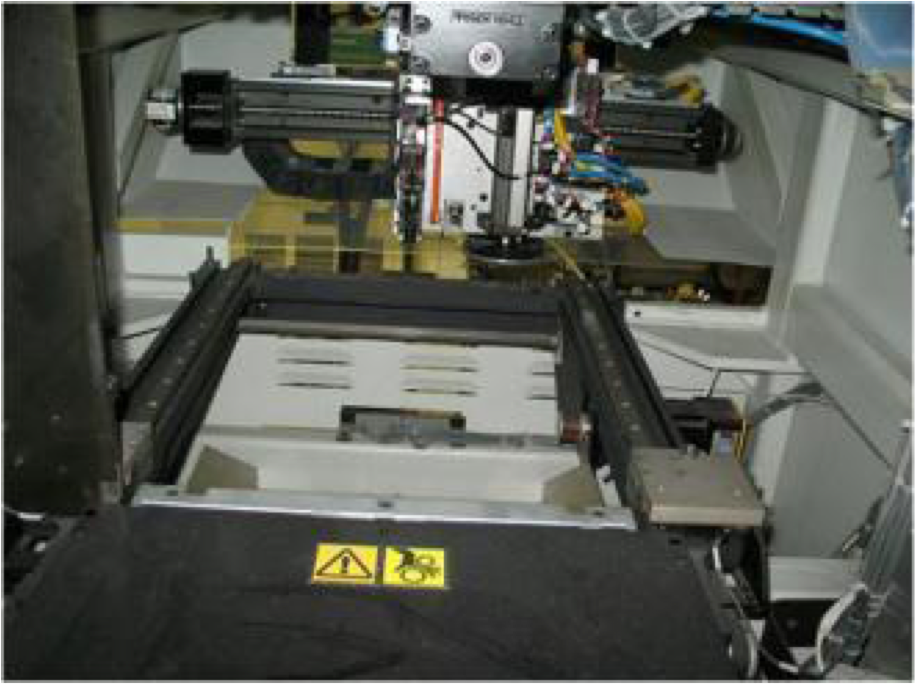

Pick and place machine

PTF unit

Flex Jet head

Software: version 4.5.0 C

2000 vintage.

UNIVERSAL GSM II is a versatile PC board assembly and manufacturing equipment. It is designed to increase productivity and throughput in the assembly and manufacture of printed circuit boards (PCBs). It incorporates a highly configurable framework that can be tailored to the individual needs of each user. The platform is based around a fully custom built X86 server running Windows 2012 Server operating system. This server is interfaced to a number of external devices and systems, such as the LaserDirect printer, the Global Data Set for designing printed circuit boards, the advanced Solder Paste Inspection unit, and the automated programmable test machine. This connected array of hardware makes up the entirety of GSM II tool. The primary feature of UNIVERSAL GSM II is its advanced vision asset. This model uses a high-resolution camera to capture images of the components on the circuit board for real-time analysis. These images are then used in the development of surface and assembly models for component placement and optimization of the final product. The equipment also includes an advanced automated optical inspection (AOI) feature which allows for advanced, repeatable inspections and verification of all parts on the board. It also allows for more intricate creation of production bills of materials. This feature can be employed for anything from quality assurance to flaw detection to the verification of final products. The Global Data Set feature allows users to store all design and production data in a single repository. With this feature, users can create new designs and access previously-saved design files quickly and easily, allowing them to maximize efficiency and reduce time. In addition, users have the ability to schedule multiple jobs and merge them into one file, allowing for faster production. Finally, the Virtual Manufacturing System (VMS) allows for real-time tracking of every part on a PCB and aids in scheduling multiple tasks. Utilizing Windows Workflow Foundation, VMS allows for tracking of process steps and downtimes, as well as the compilation of real-time product data. GSM II unit is an excellent tool for improving production times and reducing costs in the manufacture of PCBs. Its combination of advanced features creates a powerful yet flexible platform for any production environment. The machine can be easily configured and customized to user's individual needs, making it a great choice for any industry.

There are no reviews yet