Used UNIVERSAL GSM II #172193 for sale

URL successfully copied!

Tap to zoom

ID: 172193

Pick and place machine

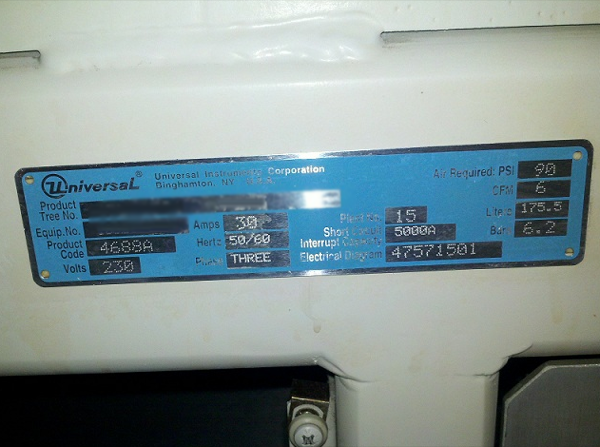

Specifications:

230V, 30 Amps, 50/60Hz, 3 Phase

90 PSI

SMEMA

Dual Beam

Flexjet/Flexjet

P-Block.

UNIVERSAL GSM II is a comprehensive pc board assembly and manufacturing equipment that supports the development, production and maintenance of a wide variety of loop and power control models. The system features a full-scale three-axis gantry robot, which is equipped with special software and hardware that provide reliable and high-precision pick-and-place operations. Moreover, the unit can be used to assemble components with pitch as low as 0.25mm on 0.6mm pitch pitch grids, as well as for thick-film wiring. The machine is equipped with an advanced vision detection tool, which provides extra precision during the pick-and-place process. Furthermore, the vision inspection asset allows the model to detect material anomalies and wrong parts, providing a high-level of safety when assembling prototypes. In addition, GSM II supports the hot and cold swapping of components, making it easy to use when prototyping. Moreover, the equipment can also detect low-value parts, as well as multiple lead components, ensuring that all components used in the board assembly and manufacturing process are reliable. The system also features an offline programming station which allows the programming of the robot arm. This programming station simplifies the robot programming process and allows users to create programs even when the robot is running. Moreover, the unit features automatic fault detection technology - an advanced feature that allows users to detect and rectify any fault that may occur during the board assembly and manufacturing process. This feature can also be used to check part compatibility, prevent short circuits and check whether the machine is working properly. UNIVERSAL GSM II also features an integrated tool pre-setter, which allows the robot arm to pick up pre-positioned tools from a rack. This eliminates the need for manual tool exchange, dramatically improving the efficiency and the overall productivity of the tool. The asset is equipped with a workpiece gripper station which provides a safe working environment for assembling boards. The gripper station allows operators to input various sizes of boards into the model, eliminating the risk of component collisions or other errors. Moreover, the equipment also supports offline printing and drying, as well as an inline component inspection system. This component inspection unit enables users to detect any errors or defects in the components before they are added to the board. Finally, the machine includes a software suite that features a powerful router, task scheduler and production tracking tool - all aimed at simplifying the management tasks associated with board assembly and manufacturing. The software is highly competitive and ensures that users can efficiently and accurately assemble their boards.

There are no reviews yet