Used UNIVERSAL GSM II #9085988 for sale

URL successfully copied!

Tap to zoom

ID: 9085988

Pick and place machine

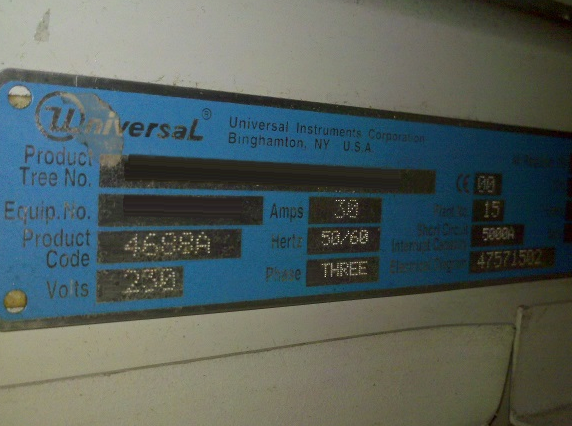

Specifications:

230V, 30 Amps, 60Hz, 3 Phase

90 PSI

Light tower.

UNIVERSAL GSM II is a pc board assembly and manufacturing equipment designed to streamline the production process of electronic assemblies. The system works by using a single-sided placement conveyor technology which is compatible with most of the currently available PC board manufacturers. The conveyor consists of an upper and lower belt that transport the PC boards to the next station. The unit can be configured for advanced automation, allowing users to configure the boards according to their own individual requirements. It is equipped with dual gantry mount heads, giving users the ability to feed components into the machine at a given rate for fast production rates. The tool is also equipped with an upper and lower swing arm for pick-and-place operations. The asset is powered by an operator terminal that gives users the ability to control all aspects of the production process. It includes a built-in monitor model, configurable programming parameters, multiple component banks, component recognition and classification, connection monitoring, visualization and simulation, component placement, and automated inspection systems. The equipment is fully automated and comes with a number of safety features, such as emergency stop buttons and automatic lid opening. It also features an easy-to-use high-quality interface with a touch screen display, providing users with an intuitive graphical interface. GSM II is capable of assembling a variety of different board types, such as thin-profiled, tightly-spaced components and double-sided boards. It also supports high-density surfaces, via its multi-focal head placement system. It is designed to handle up to 2000 different components per hour, thus making it one of the most efficient systems of its kind. The unit is capable of handling high-speed dual-wave placement, giving users the ability to run at rates of up to 120 components per second if adjusted correctly. This makes it ideal for high-volume production lines. The machine is equipped with various inspect systems, measuring tools, and verification techniques for reliable and accurate operation. In addition, UNIVERSAL GSM II is equipped with vision inspection systems to ensure each layer is inspected independently. It also features high-fidelity press-Fit accuracy for accurate alignment and placement of components. Finally, it offers a number of inspection options, such as hot bar reflow, wave soldering, and thermal profiling.

There are no reviews yet