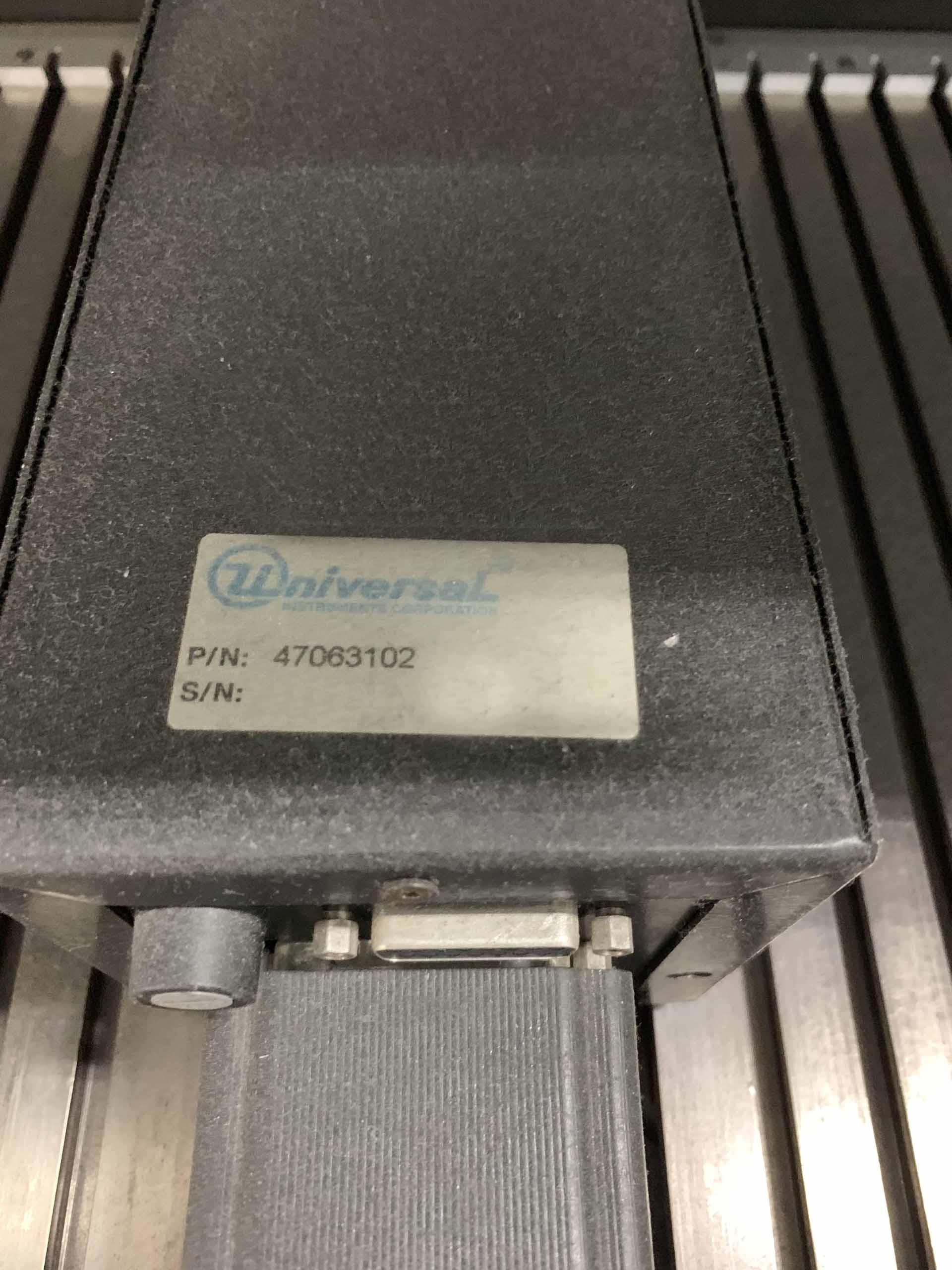

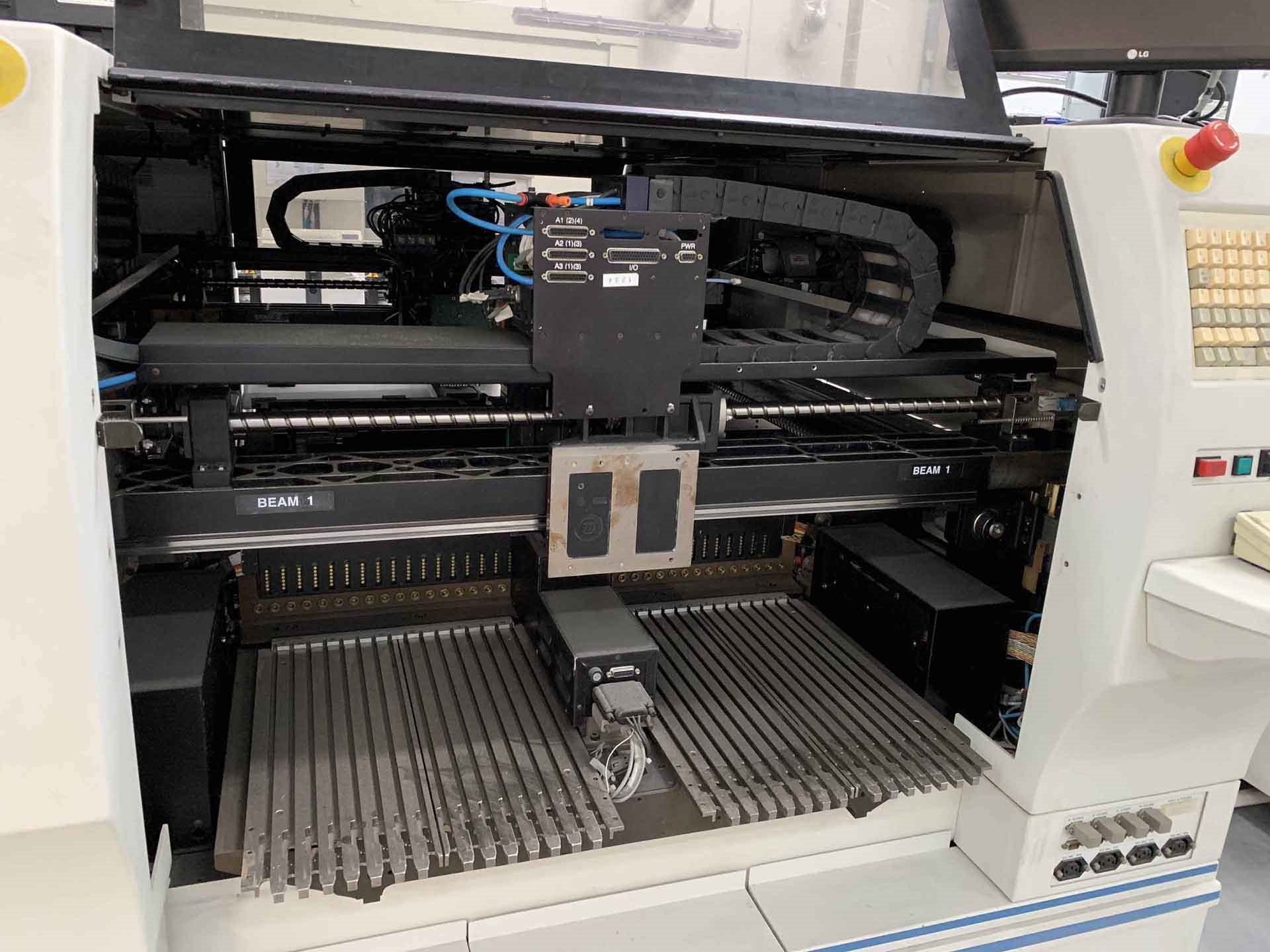

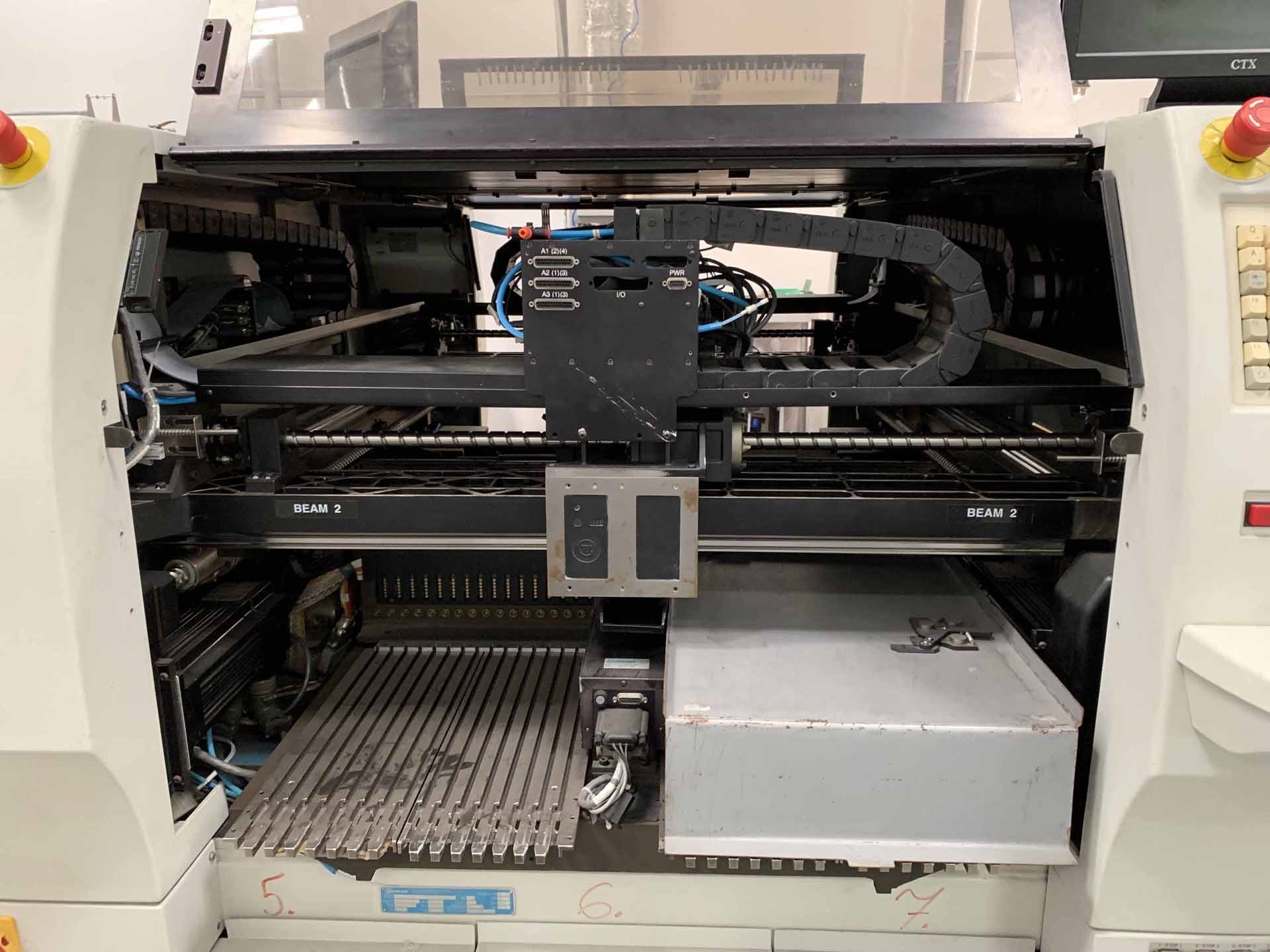

Used UNIVERSAL GSM II #9197641 for sale

URL successfully copied!

Tap to zoom

ID: 9197641

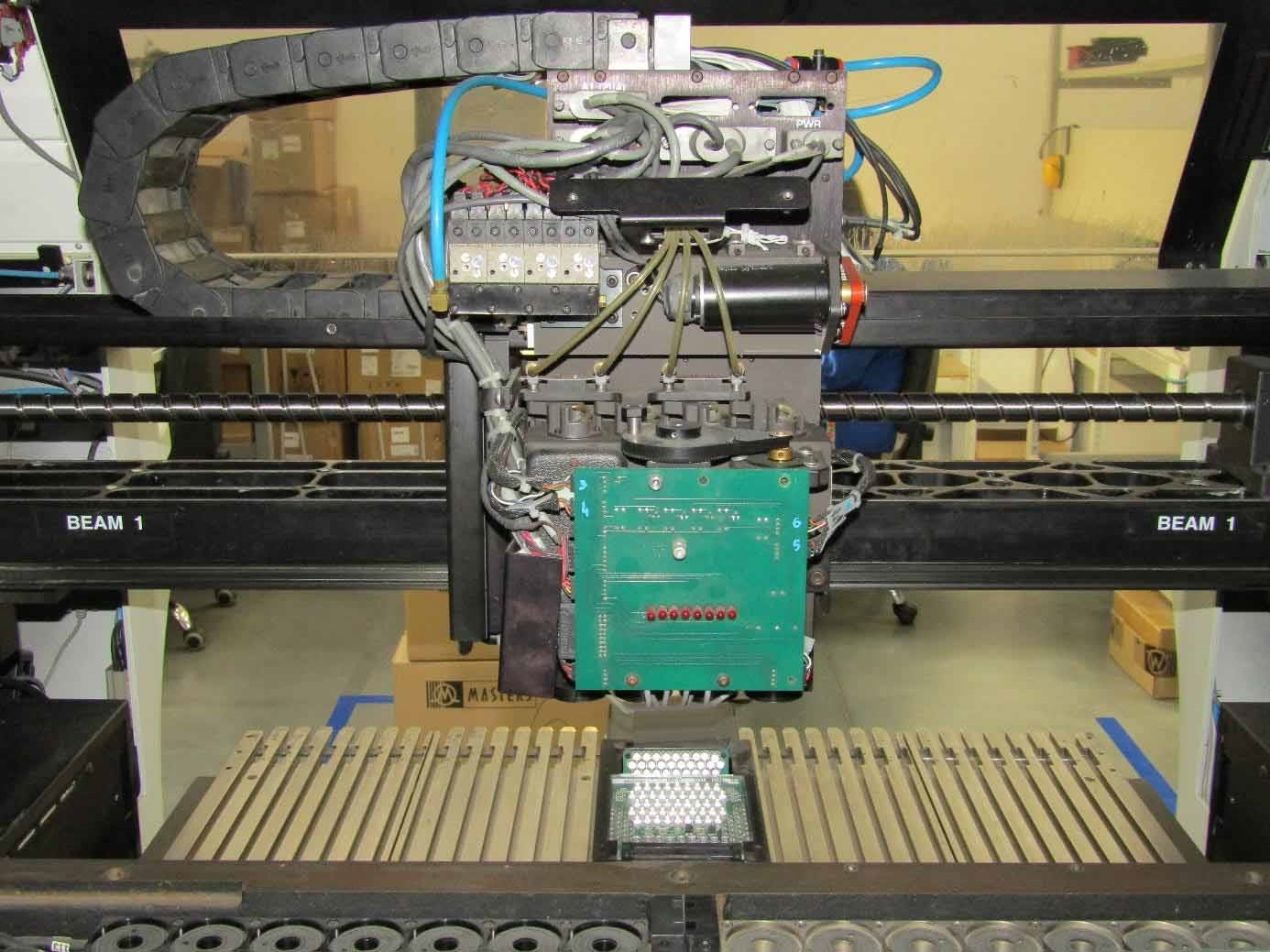

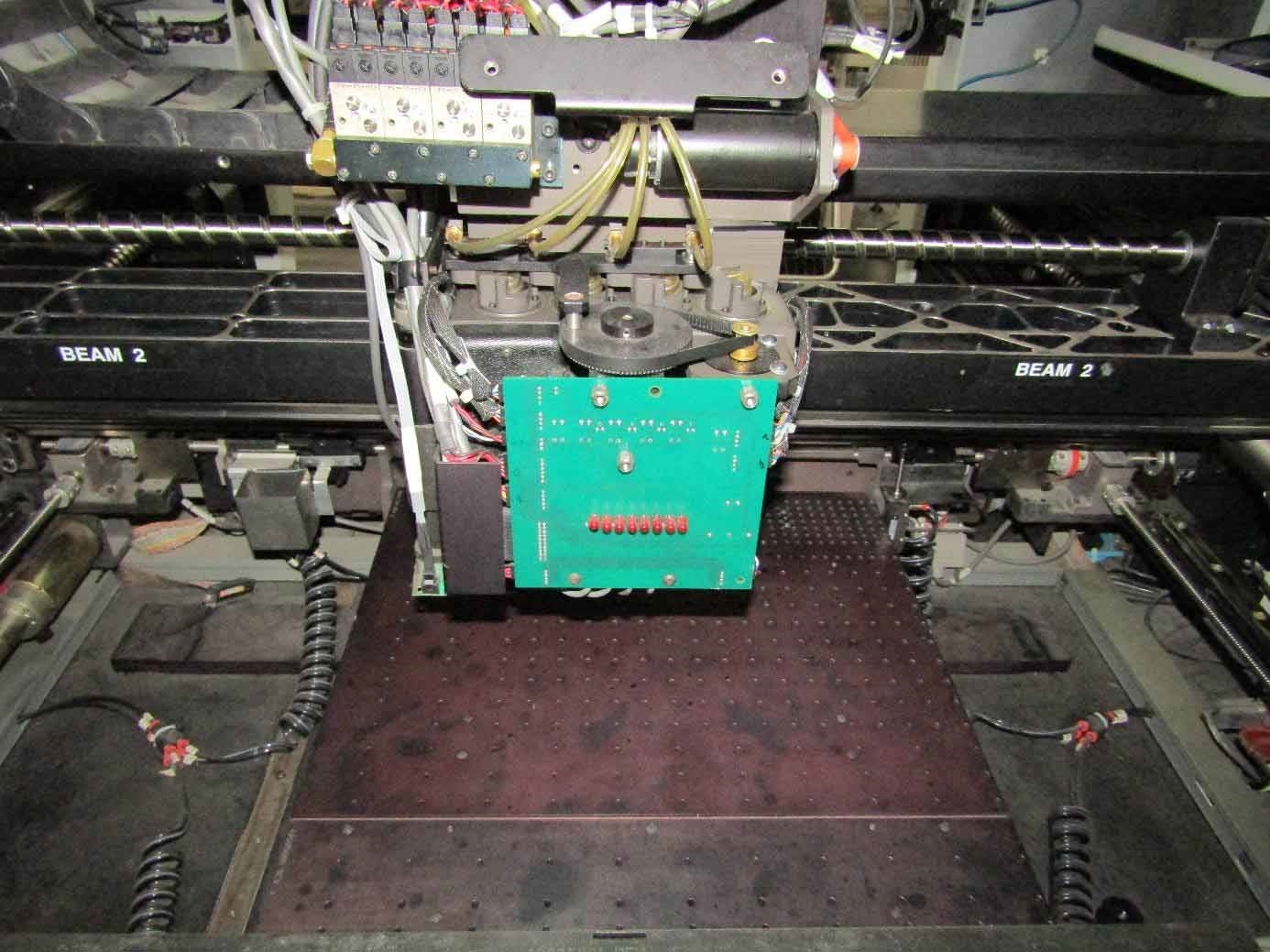

Pick and place machine

Final placement performance:

X,Y Accuracy: +/- 0.00150" (0.0381 mm)

X,Y Repeatability: < 0.000667" (0.0169 mm)

Rotational accuracy: +/- 0.06°

Rotational repeatability: <0.0466°

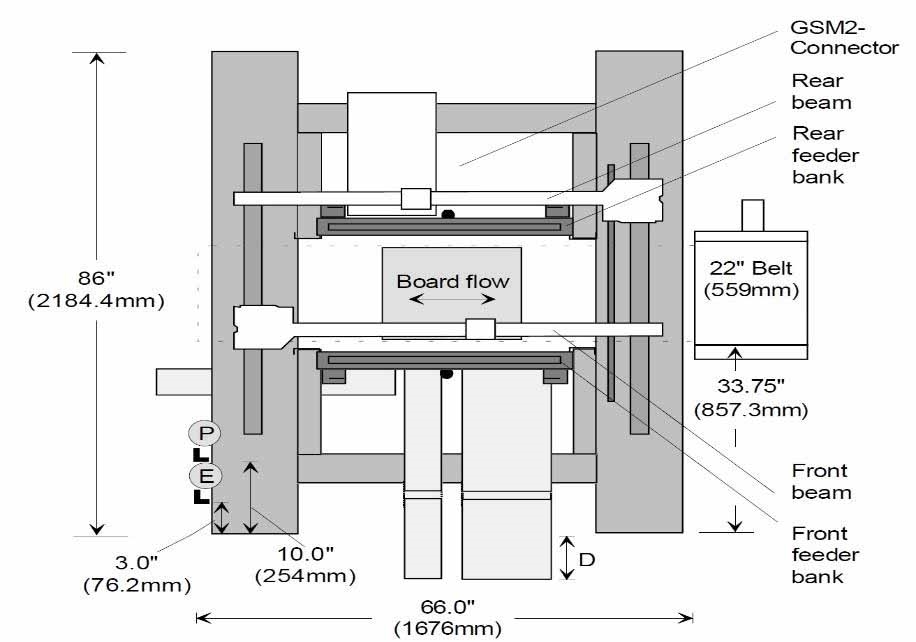

UIC GSM2 Board parameters:

Maximum: 20" x 18 " (508 mm x 457 mm)

Minimum: 2" x 2" (51 mm x 51 mm)

Board thickness: 0.020" (0.508 mm) to 0.200" (5.08mm)

Top side clearance: 0.500" (12.7 mm)

Bottom side clearance: Dependent on component

Orientation: 0.500" (12.7 mm)/ 1.0" (25.4 mm)

Registration:

Top edge register

Front edge register

Tooling pin

Vision (PEC)

Transfer direction: Left to right

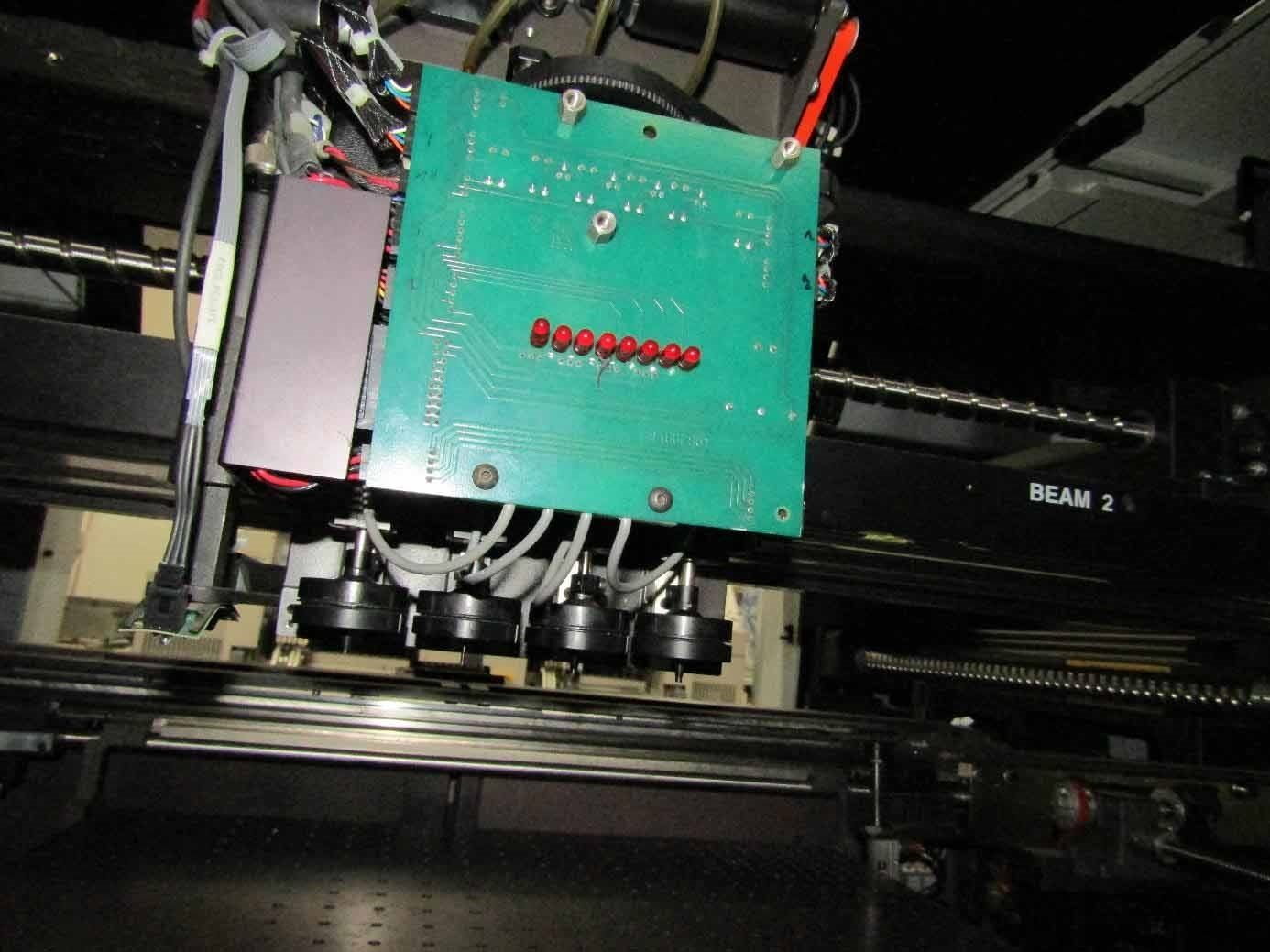

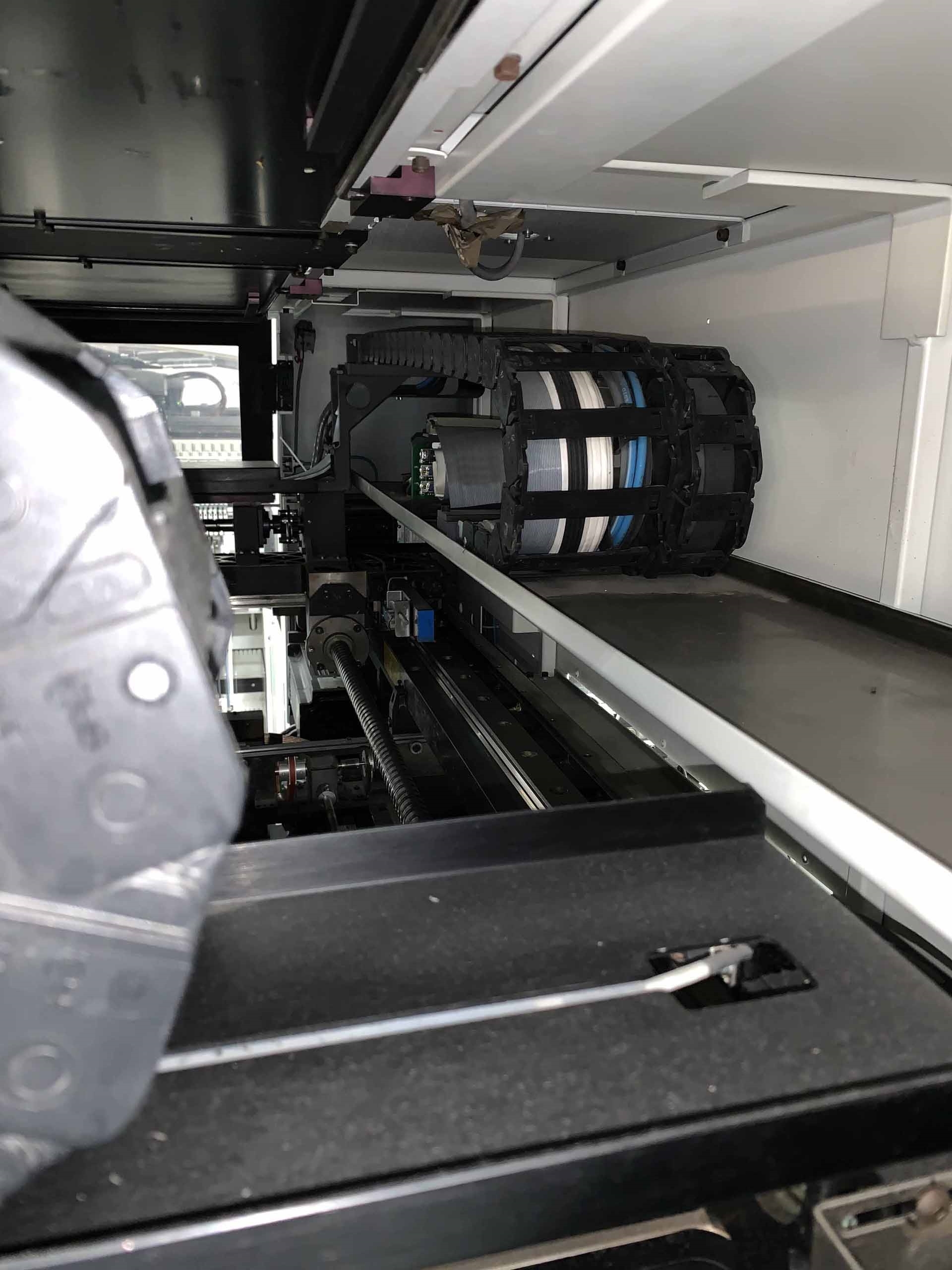

Flex head:

(4) Spindle heads

Component placement force range: 150-450g in 100 gram increments

Final placement performance: 75% Lead to pad at 6s by placement

Intrinsic availability: < 98%

Flex head on GSM platform

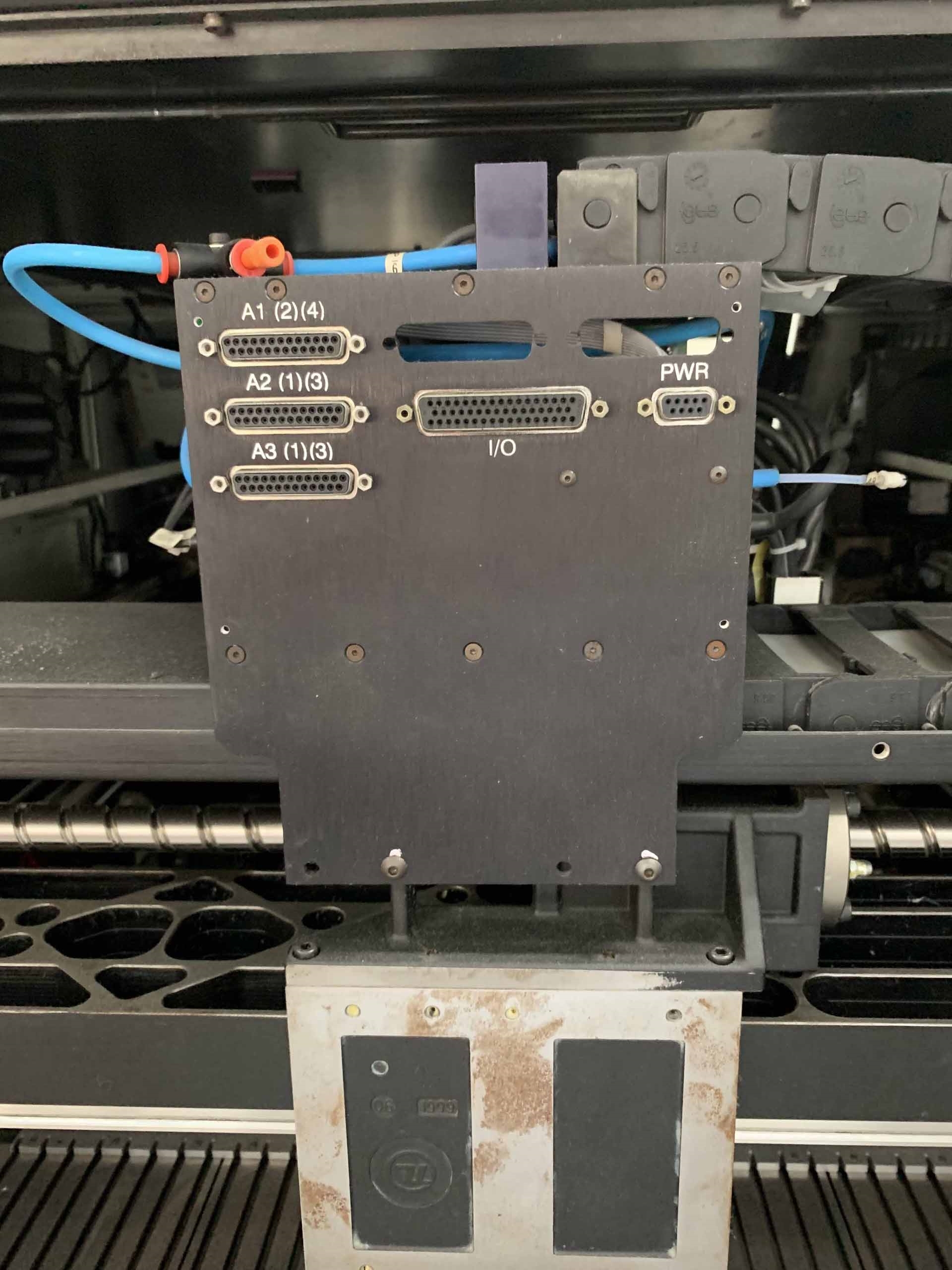

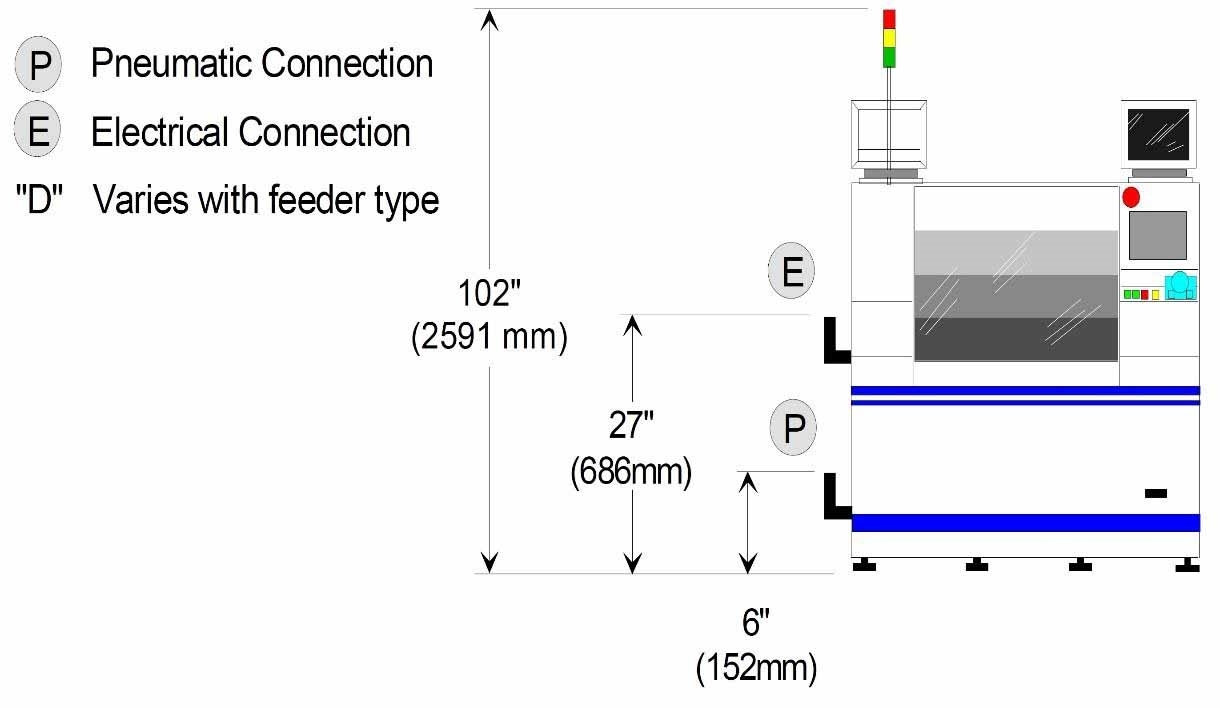

Power supply: 230 VAC, 50/60 Hz, 3 Phase, 30 Amps.

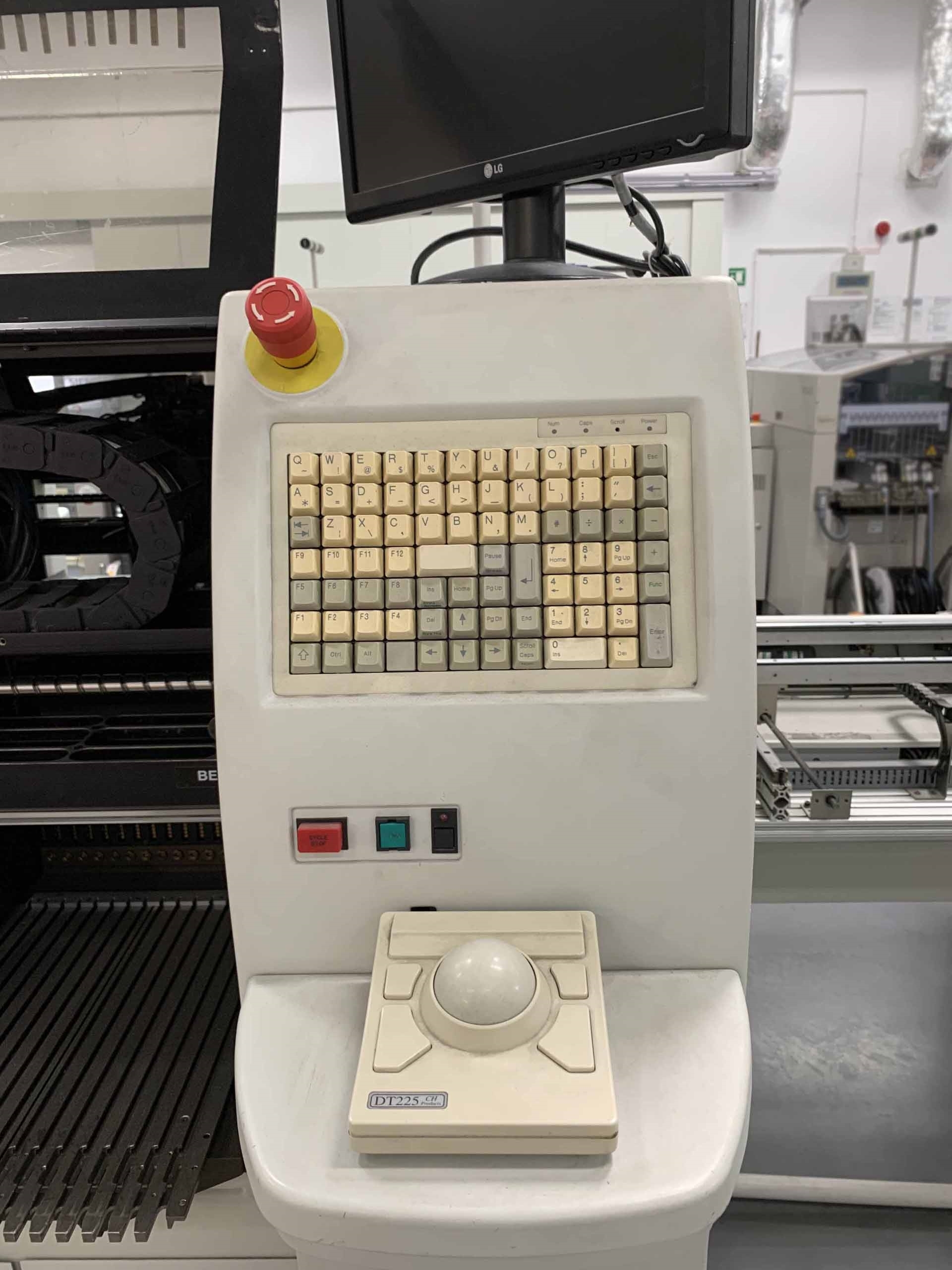

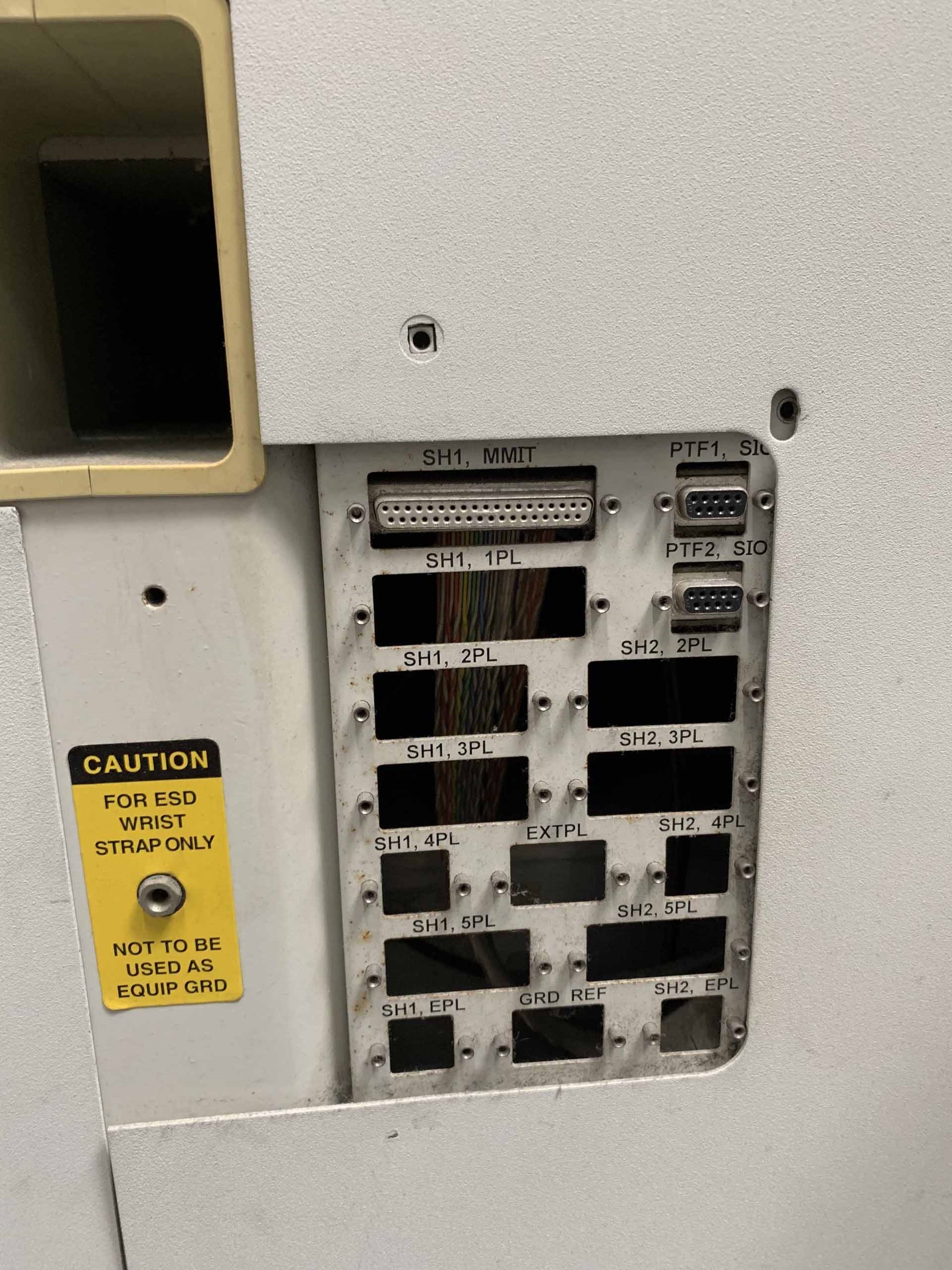

UNIVERSAL GSM II is a comprehensive system for the assembly and manufacturing of printed circuit boards (PCBs). It provides all the tools necessary for efficient and cost-effective production of PCBs from design to completion. GSM II consists of an interconnected suite of software and hardware components. It includes a CAD CAM system which includes both design and engineering features for rapid, efficient development of PCBs. Its associated CAM (computer aided manufacturing) software automates the entire manufacturing process and provides tools for optimizing PCB layout and land pattern placement, surface mount technology (SMT) component insertion and array building, and routing circuitry on the PCBs. Its hardware components include a pick-and-place machine, reflow oven, and stencil printer. The pick-and-place machine is used to transfer components from a tray to the appropriate location on the printed circuit board. The reflow oven heats the components to the proper temperature to ensure proper soldering. The stencil printer is designed to print perforation patterns on the stencil, allowing the components to be placed accurately and precisely. UNIVERSAL GSM II also includes SMT component placement software which is designed to precisely locate components on the board. It can be calibrated to measure component size and conform to specific part geometries. This allows a variety of different complex board designs to be created with minimum effort. Additionally, GSM II offers testing of PCBs and component soldering. This process is fast and simple and reduces reworks and defect rates. The system's quality assurance module helps monitor and improve efficiency and reduces total manufacturing and overhead costs. The comprehensive suite of tools provided by UNIVERSAL GSM II makes it a popular choice for assembly and manufacturing of electronics and printed circuit boards. It is also reliable, cost-effective, and offers significant savings in production time.

There are no reviews yet