Used UNIVERSAL GSM II #9197642 for sale

URL successfully copied!

Tap to zoom

ID: 9197642

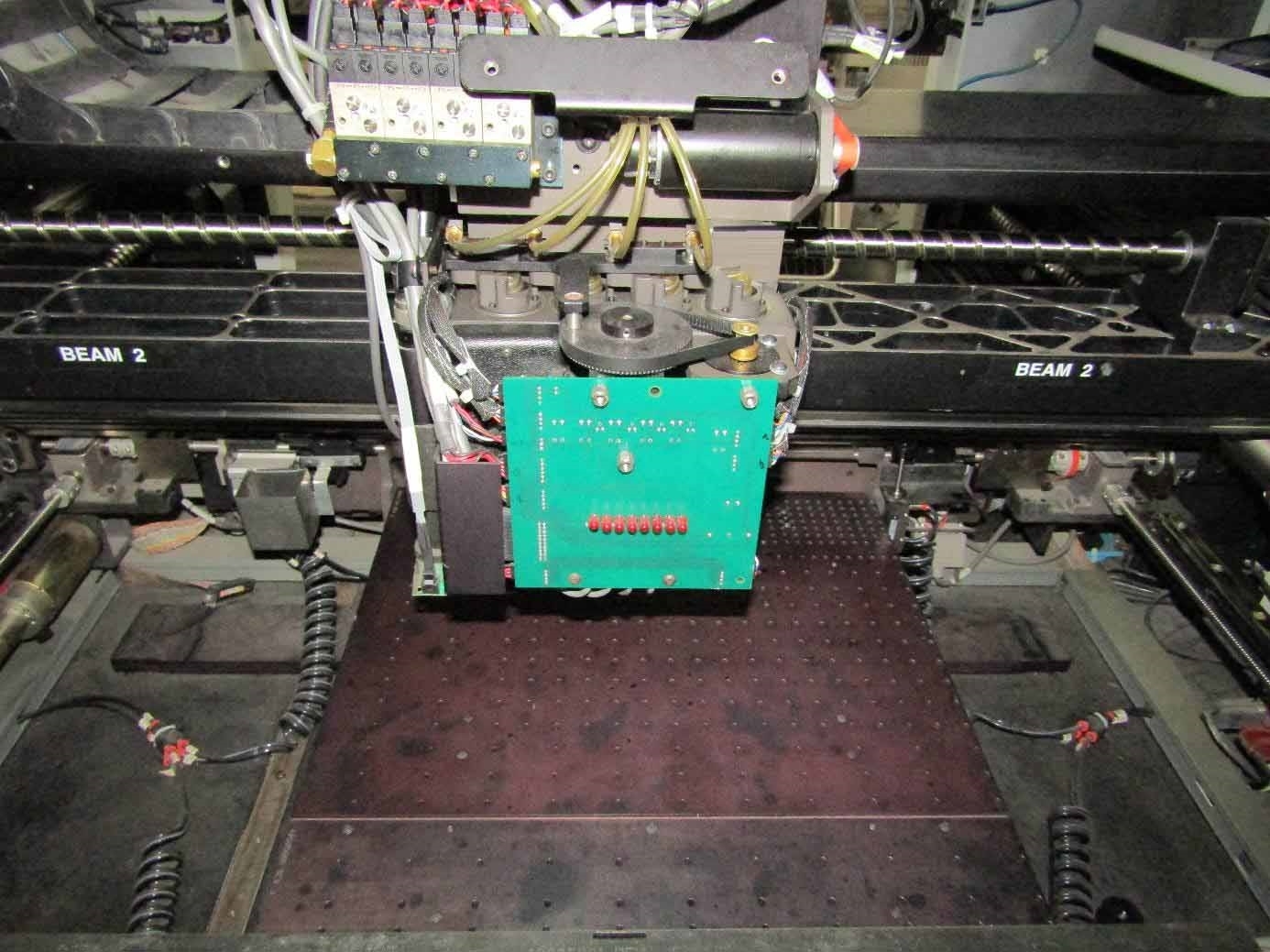

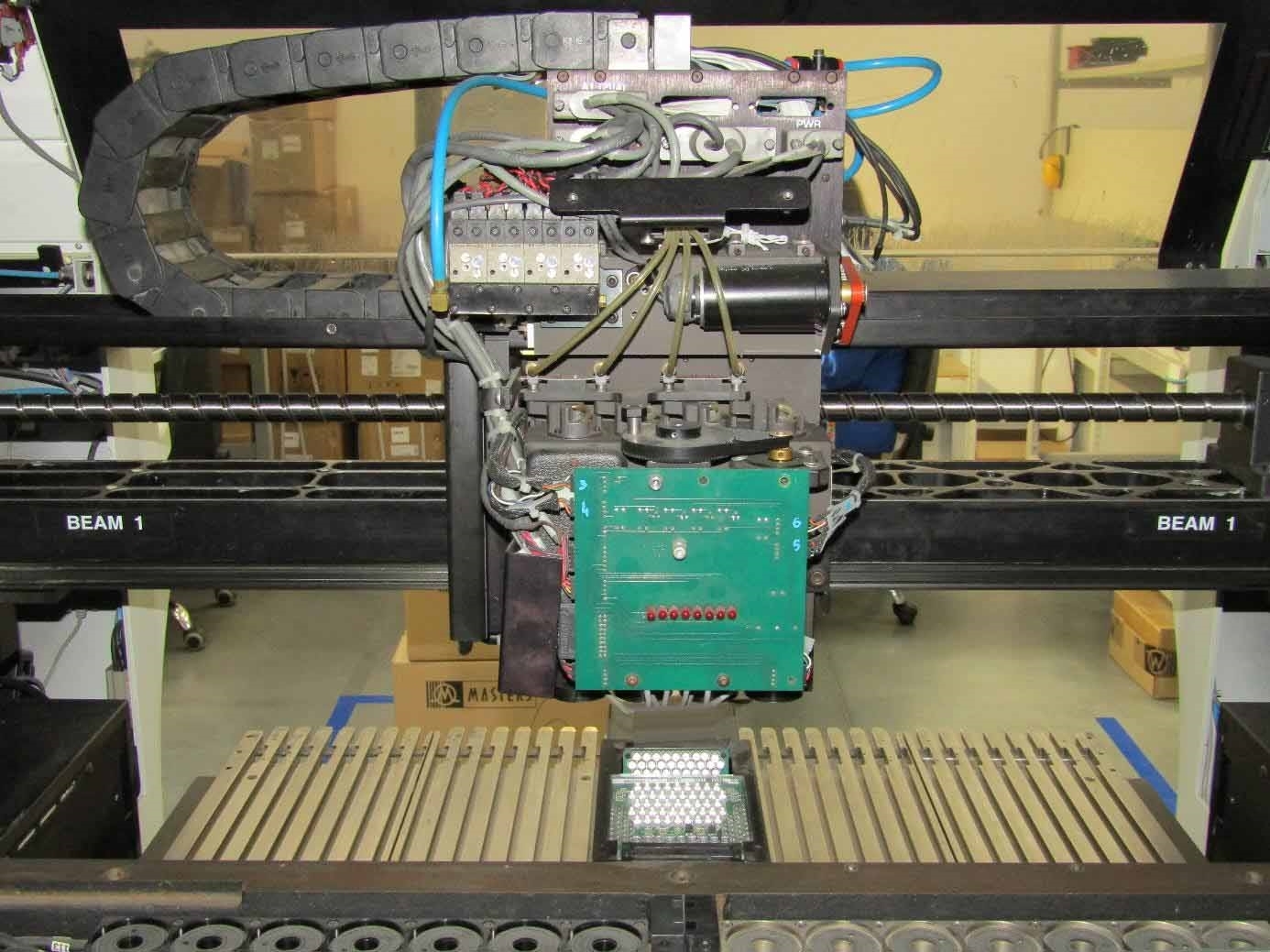

Pick and place machine

Final placement performance:

X,Y Accuracy: +/- 0.00150" (0.0381 mm)

X,Y Repeatability: < 0.000667" (0.0169 mm)

Rotational accuracy: +/- 0.06°

Rotational repeatability: <0.0466°

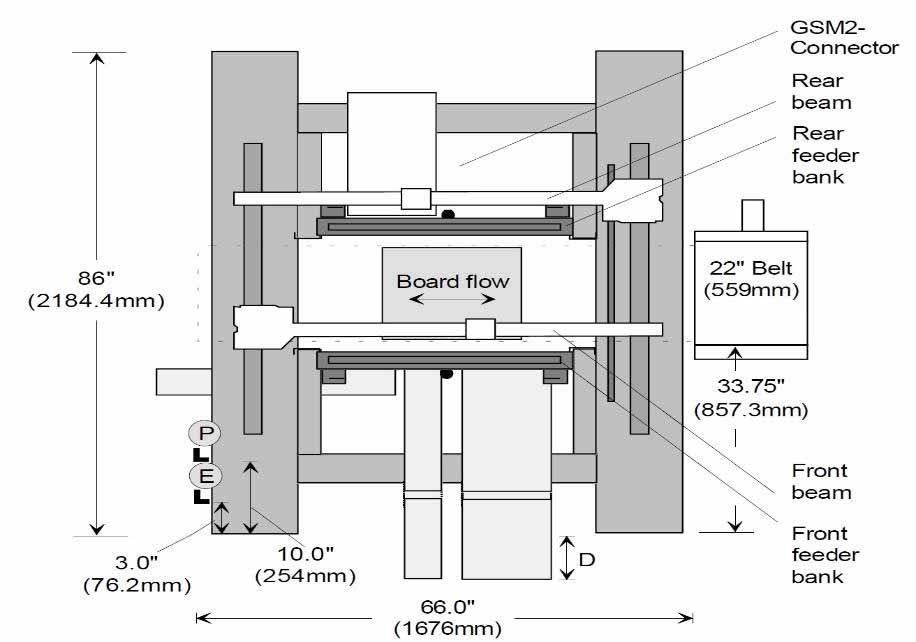

UIC GSM2 Board parameters:

Maximum: 20" x 18" (508 mm x 457 mm)

Minimum: 2" x 2" (51 mm x 51 mm)

Board thickness: 0.020" (0.508 mm) - 0.200" (5.08 mm)

Top side clearance: 0.500" (12.7 mm)

Bottom side clearance: Dependent on component

Orientation: 0.500" (12.7 mm) / 1.0" (25.4 mm)

Registration:

Top edge register

Front edge register

Tooling pin

Vision (PEC)

Transfer direction: Left to right

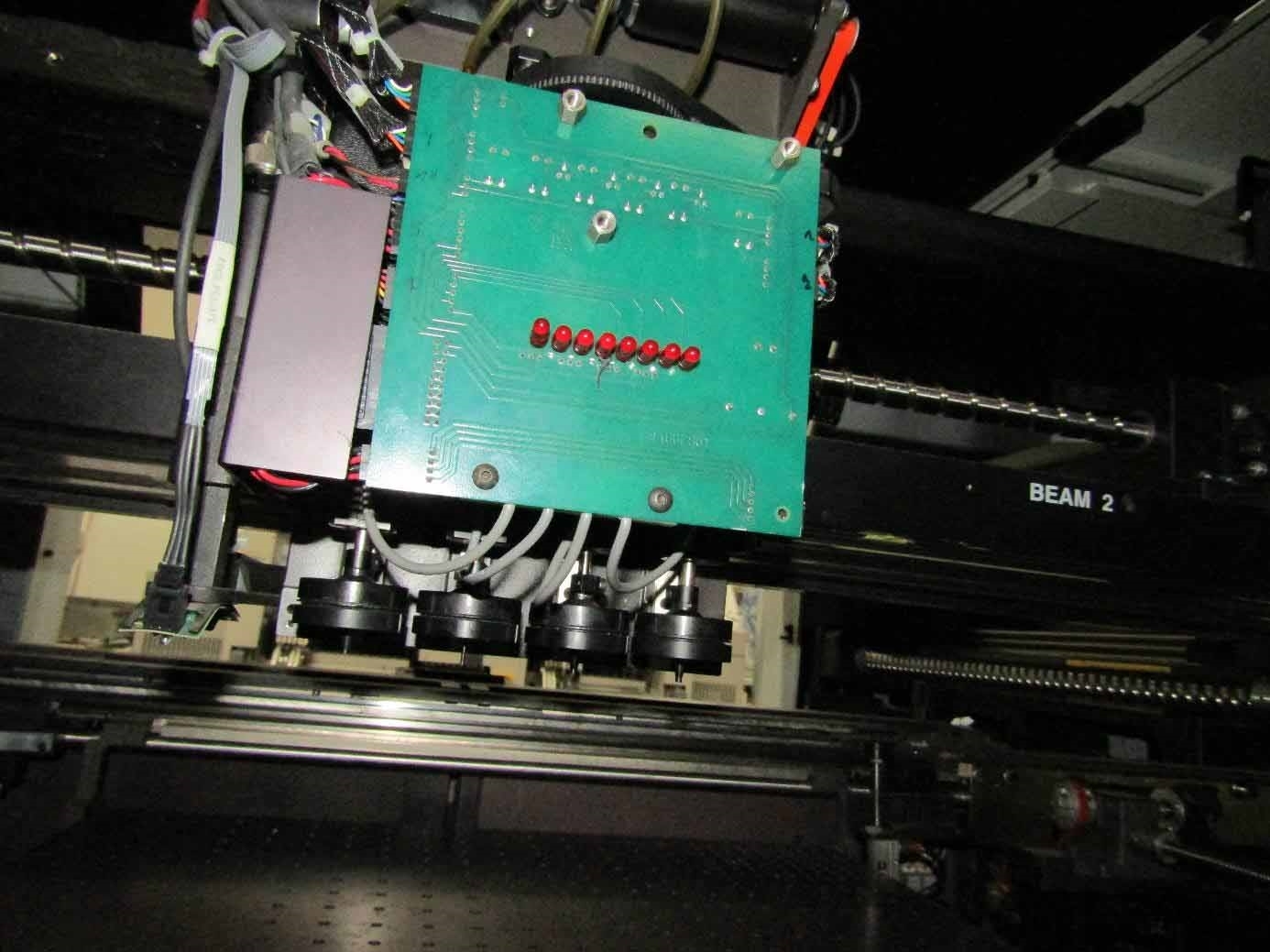

Flex head:

(4) Spindle heads

Component placement force range: 150-450 g - in 100 gram increments

Final placement performance 1: 75% Lead to pad at 6 sec by placement

Intrinsic availability: < 98%

Flex head on GSM platform

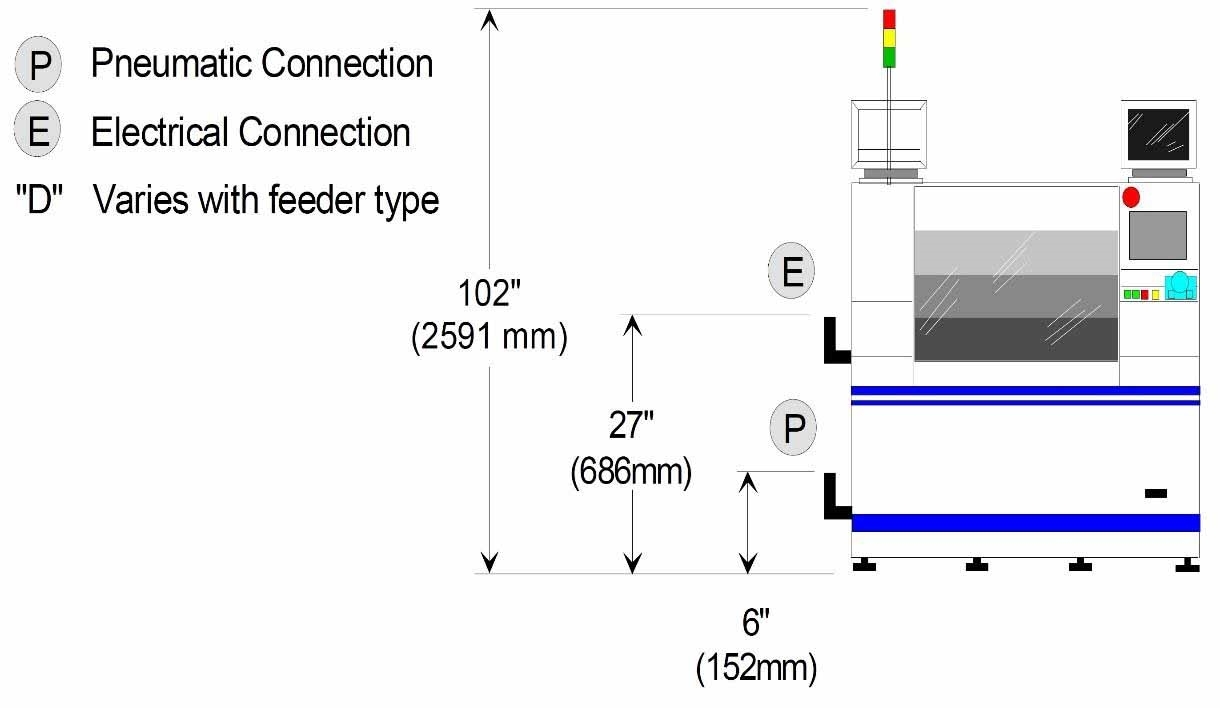

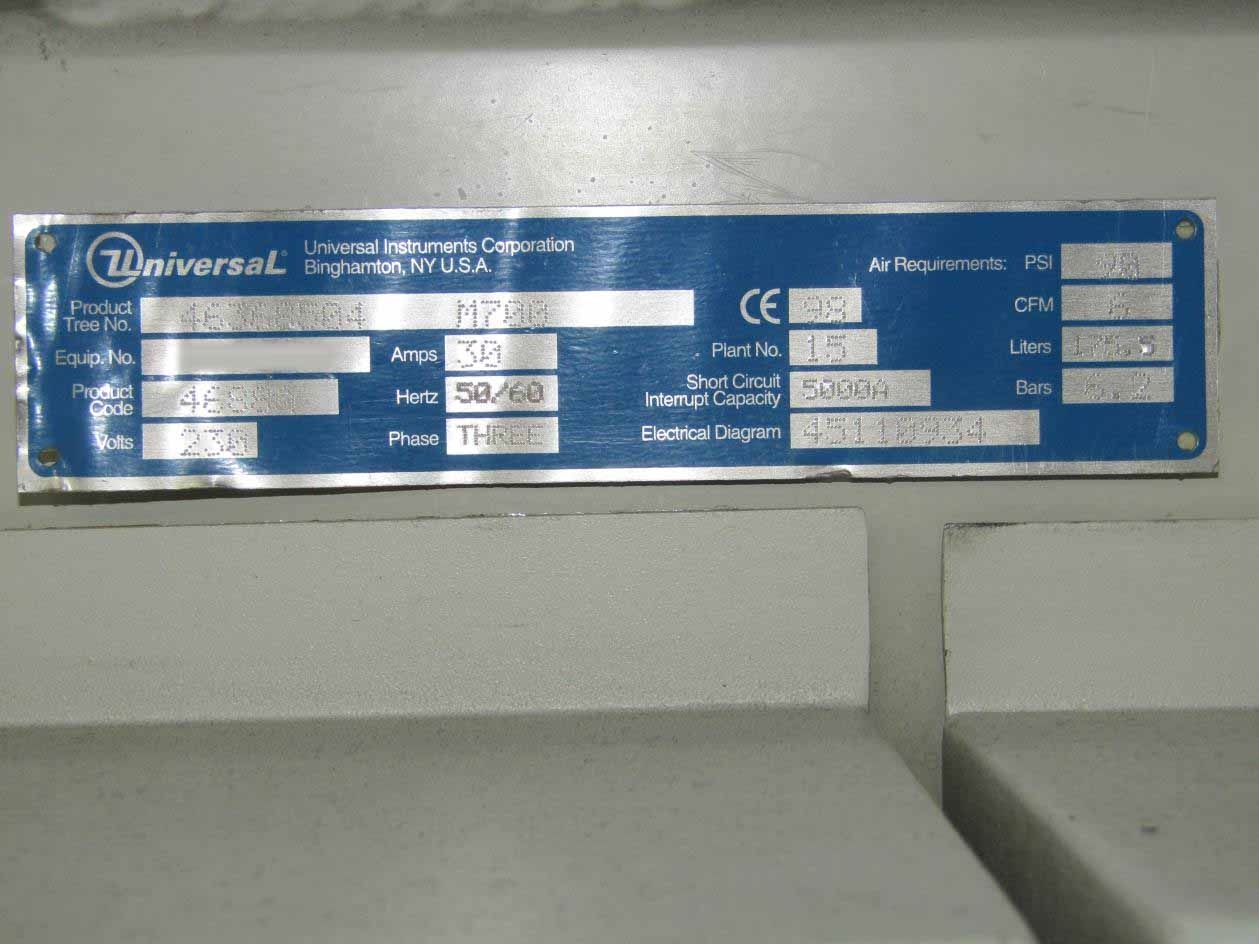

Power supply: 230 VAC, 50/60 Hz, 3 Phase, 30 Amps.

UNIVERSAL GSM II is a PC board assembly and manufacturing equipment developed by UNIVERSAL Instruments Corporation. The system utilizes advanced PCB-level technology that allow for fast and accurate production of high-density electronic assemblies. GSM II can fabricate multi-layer circuit boards with up to 12 layers. It supports built-in hardware for design and quality control, including automatic placement of components on top and bottom sided of the board, as well as image recognition for identification of components. The unit also has features for solder fillet inspection and soldering quality control. UNIVERSAL GSM II can process a wide range of components, from standard through-hole to surface mount devices (SMD), such as high-density quad-FSBG (Fine-Pitch Surface-Mounted Ball Grid arrays) and ultra high-density passive components. The PCB embedding technology increases efficiency by enabling parts to be mounted directly onto the substrate without lead frames. The machine has an advanced measurement tool built in for precision placement accuracy and alignment verification. The asset also utilizes an electrical test module to detect errors in the assembly line such as shorts, opens, reversed components and incorrect orientations. The model is compliant with military-specifications, such as Mil-Spec 85903-B for soldering and RoHS for environmental protection. The equipment has traceability and data integrity features to ensure product labeling is effective and simplified compliance, so customers can remain aware of product data accuracy. The system is well suited for high-volume production applications, especially those with challenging form factors and ultra high-density PCBs with fine-pitch components, as the unit is able to produce accurate assemblies with a high level of quality and accuracy. This in turn reduces the cost of production as fewer returns and reworks are required. Overall, GSM II provides a complete solution for assembling and manufacturing printed circuit boards, as it can handle a wide range of components with precision and accuracy. It also has features that help reduce production costs while ensuring high levels of quality and traceability.

There are no reviews yet