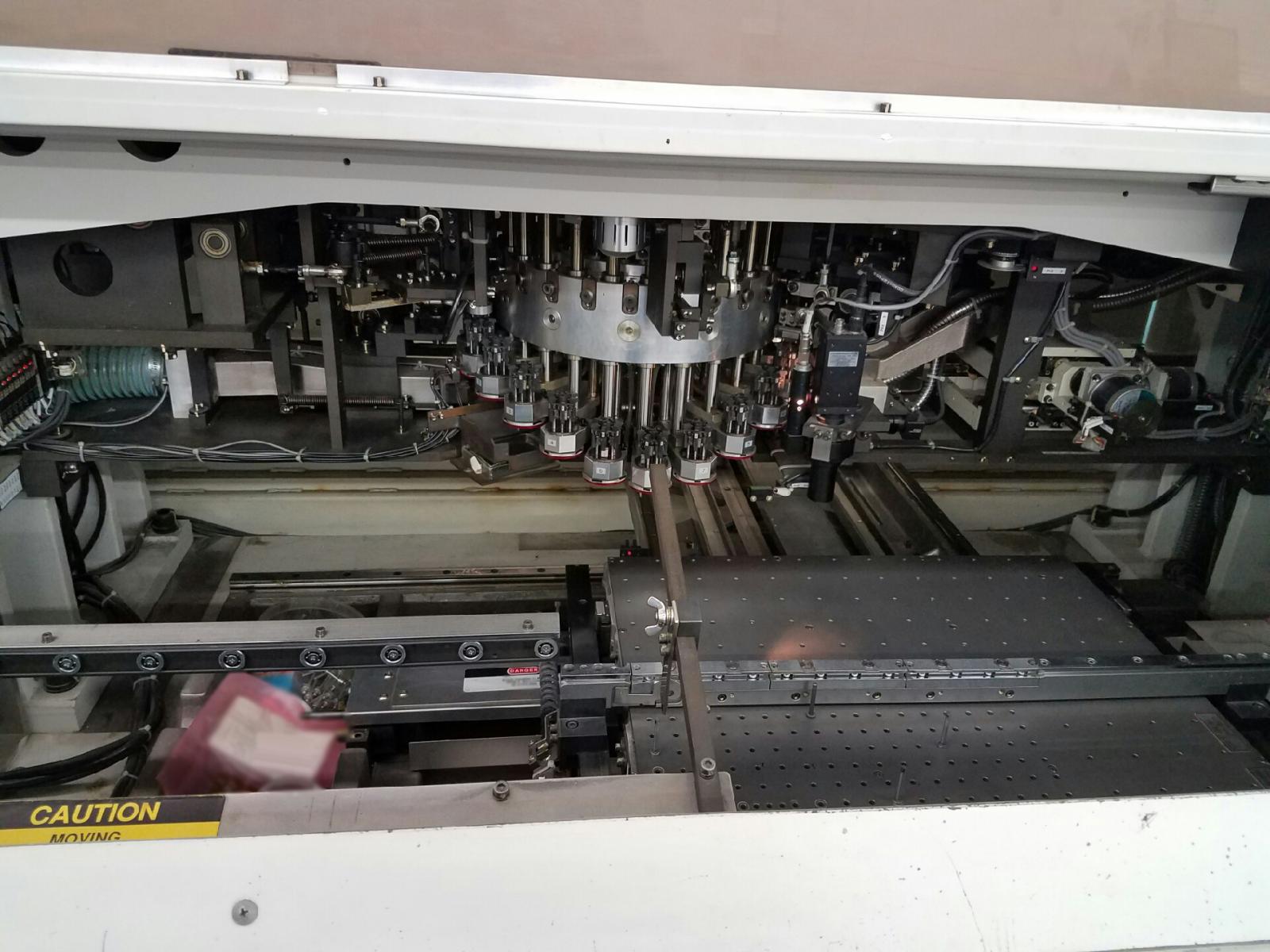

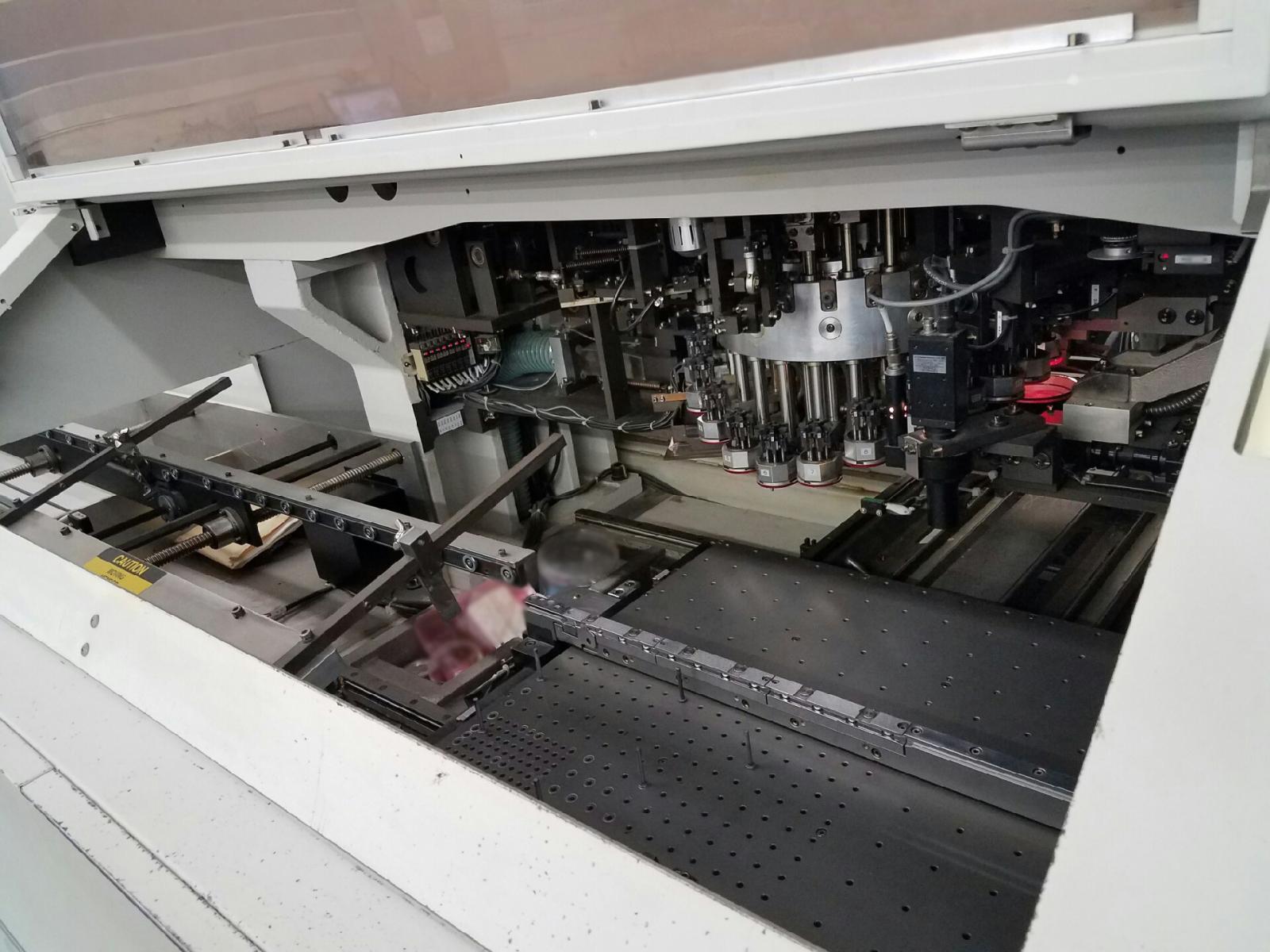

Used UNIVERSAL HSP 4791 #9153196 for sale

URL successfully copied!

Tap to zoom

ID: 9153196

Pick and placement machine

Feeders:

(84) 8mm x 4mm

(5) 12mm x 4mm

(7) 12mm x8mm

(5) 16mm x 8mm

(5) 16mm x 12mm

(5) 16mm x 16mm

(9) 24mm x 8mm

(9) 24mm x 12mm

(9) 24mm x 16mm.

UNIVERSAL HSP 4791 pc board assembly and manufacturing equipment is a state-of-the-art, multi-function system designed for complex printed circuit board (PCB) assembly and manufacturing. The unit is ideal for both low and high-volume production of both prototype and medium/large runs of PCBs. The machine integrates four major areas of PCB assembly technology for increased efficiency and faster results: automated soldering, laser marking, component placement, and component visual inspection. The automated soldering process of HSP 4791 utilizes a high-performance robotic soldering arm. This arm efficiently places the components to be soldered on the PCB. The integral laser marking module then marks all components with identifying information to streamline the assembly process. To ensure uniform placement of components, the tool employs vision-guided placement of SMT and Through-Hole components. This is done with the help of a three-axis vision asset and a wide array of placement components such as rulers, needles, tweezers, and vacuum cups. The visual inspection process of UNIVERSAL HSP 4791 also uses a three-axis vision model to inspect completed PCBs. This inspection process can identify any components in the wrong orientation, non-soldered components, and other assembly errors. In addition, the equipment can also detect corrosion, breakage, or other cosmetic issues. Overall, HSP 4791 pc board assembly and manufacturing system is a robust and reliable unit. The integration of automated soldering and laser marking, component placement, and visual inspection capabilities offer unequalled productivity and accuracy. The machine is the perfect solution for quickly creating high-quality printed circuit boards for any application.

There are no reviews yet