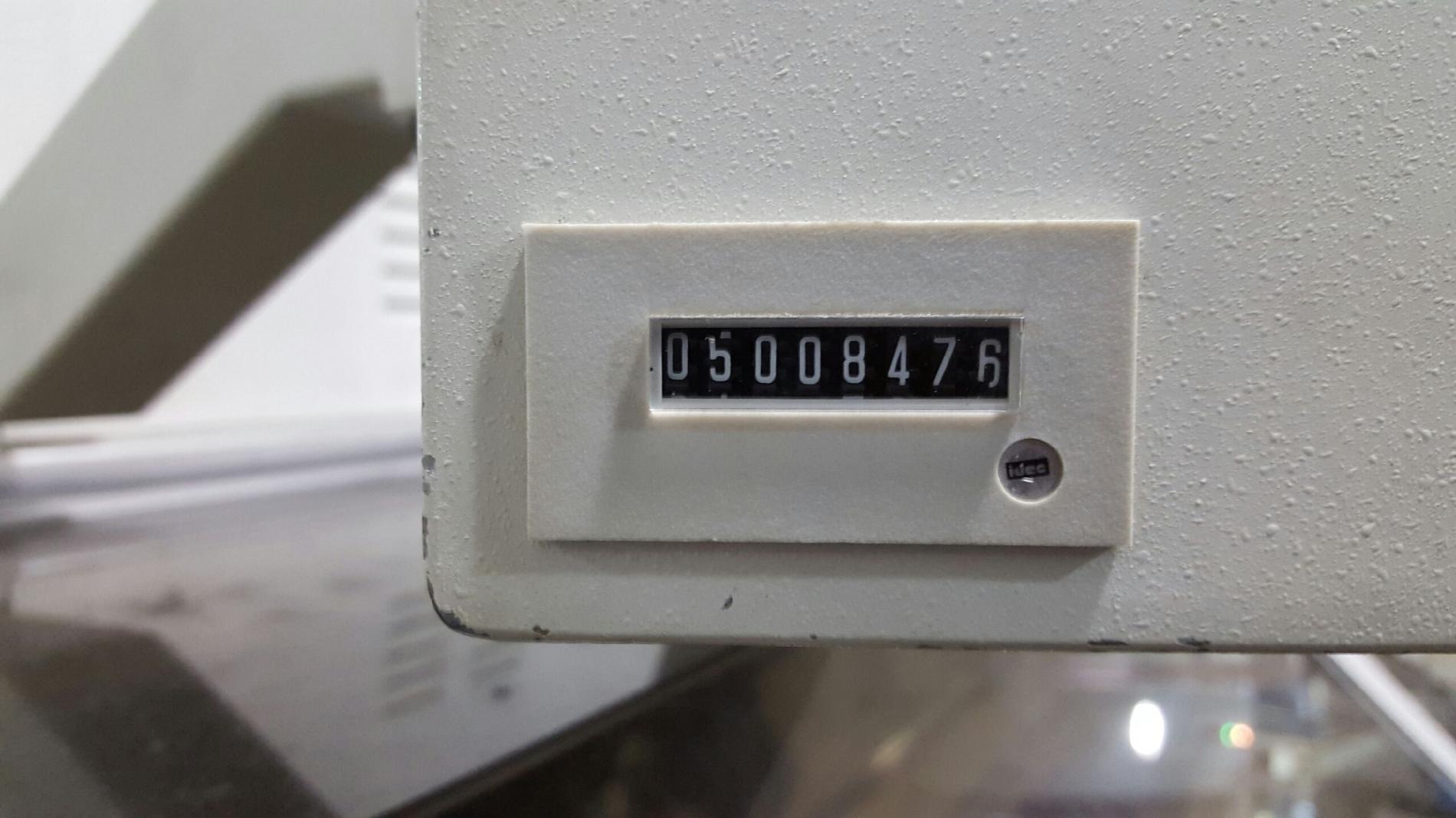

Used UNIVERSAL HSP 4796A #9165856 for sale

URL successfully copied!

Tap to zoom

UNIVERSAL HSP 4796A is a comprehensive high-speed printed circuit board assembly and manufacturing equipment developed to meet the ever-growing demands of the most advanced electronic manufacturers. This system is used to drastically reduce production time, while ensuring product consistency and accuracy. It features advanced surface mount technology components that are accurate and customized to suit specific needs. The unit's Intelligent Component Placement (ICP) technology provides for fast, more accurate placement of surface mount technology (SMT) components. The ICP offers multiple placement modes and functions such as area recognition, board and component image recognition, and the ability to place both small and large components. The use of ICP technology allows the machine to easily identify and pick components with a very high degree of accuracy. HSP 4796A is also equipped with a highly sensitive inspection machine that can detect any defects quickly. It features advanced inspection technologies such as fine-pitch vision camera, X-ray connection inspection, and 3D surface scanning. These technologies are used to inspect the quality of the components, examine the connections between components, and check the board's overall accuracy. The tool also has a Hi-Speed Inline Rear Laser Soldering Asset (RLSS). The RLSS offers high-speed soldering of both large and small components. It features adjustable Power/Time/Gap settings, pinpoint soldering accuracy, and easy calibration of the laser parameters. This ensures that each and every component is soldered perfectly and that there is no thermal stress on the board. UNIVERSAL HSP 4796A has built-in-process monitoring and control systems for maximum quality assurance. It offers a Machine Monitoring Model (MMS) for real-time monitoring of the manufacturing process. It is also equipped with an in-depth log of production records, error records, process delays and alerts. This helps to monitor and improve product quality and enable a faster response to production errors. Overall, HSP 4796A is a powerful PCB assembly and manufacturing equipment that combines state-of-the-art design, components, and technologies. It offers fast and accurate placement of SMT components, advanced inspection systems, and a Hi-Speed Inline Rear Laser Soldering System. This unit ensures efficient production of components with a high degree of accuracy and quality.

There are no reviews yet