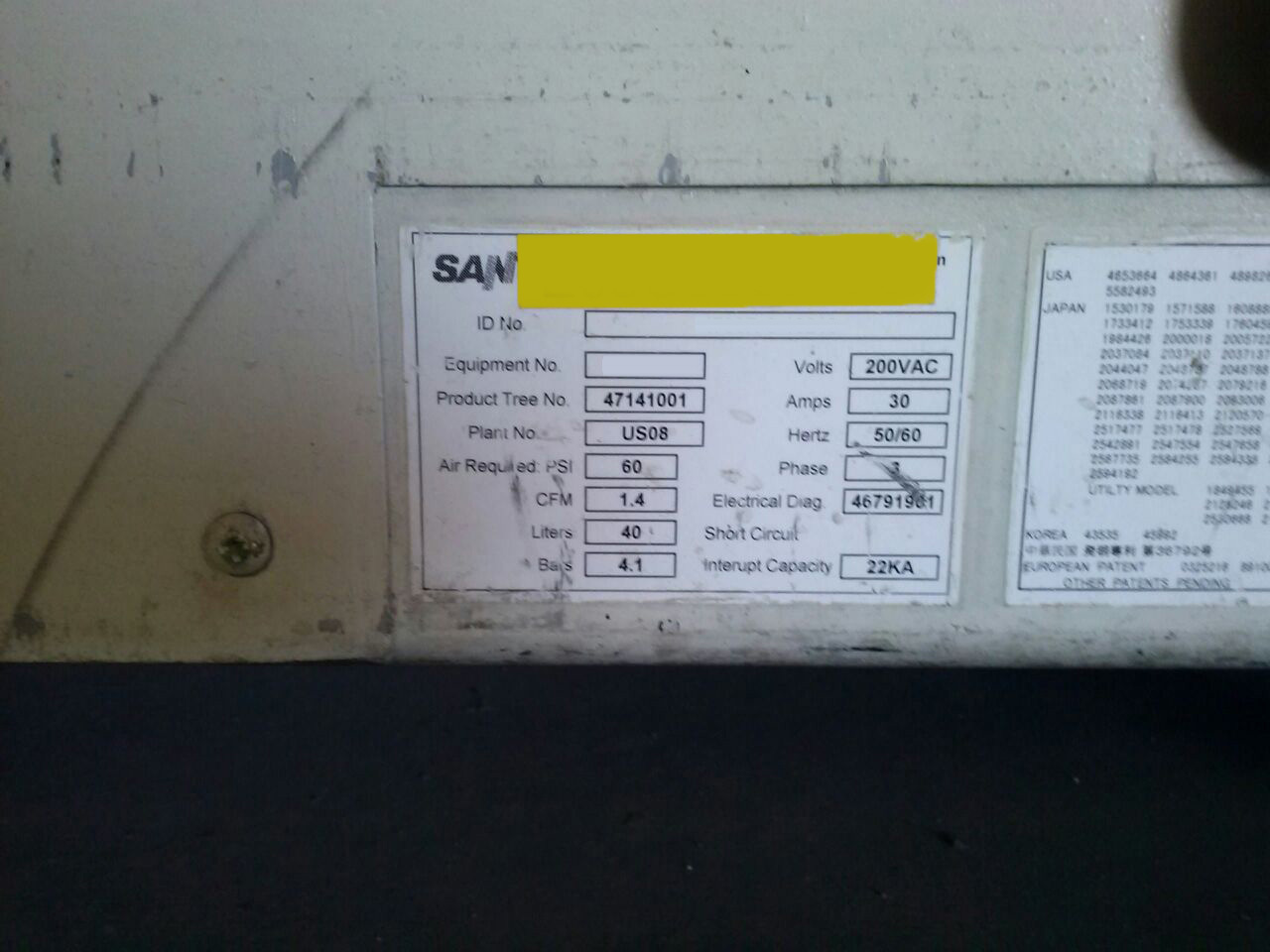

Used UNIVERSAL HSP 4796R #9075343 for sale

URL successfully copied!

Tap to zoom

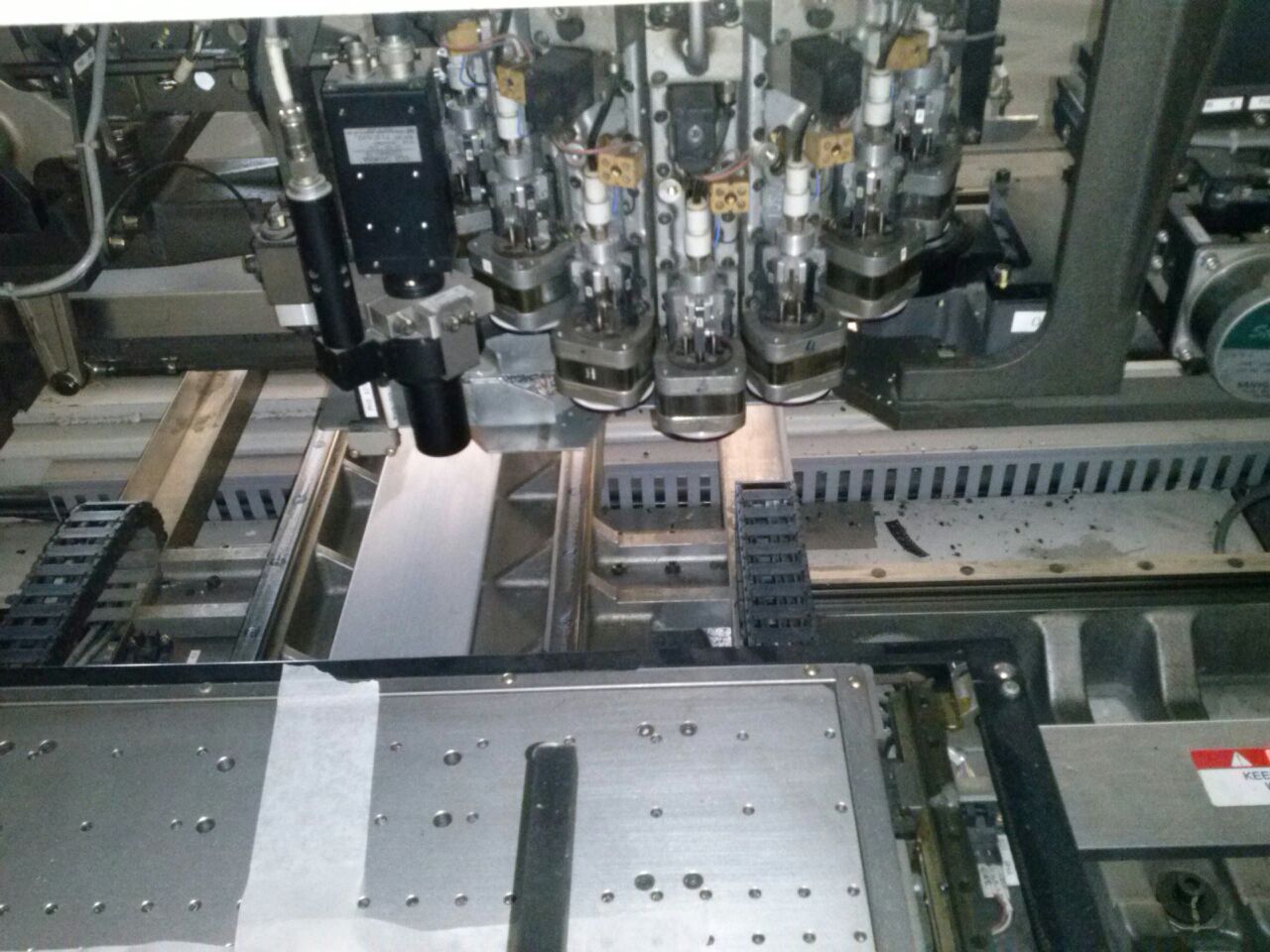

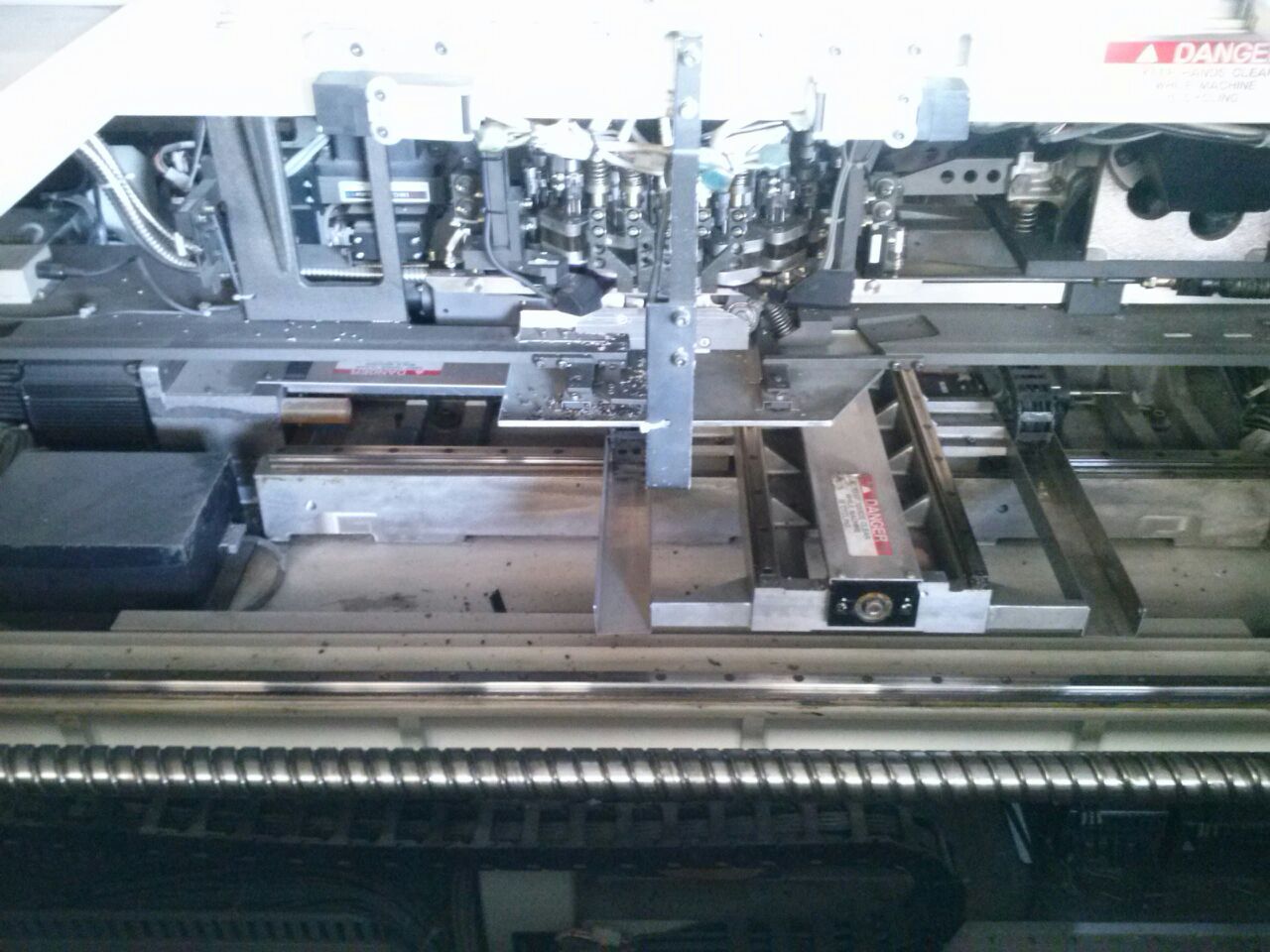

UNIVERSAL HSP 4796R is a PC board assembly and manufacturing equipment that can effectively handle the needs of high-volume production lines. The system consists of a variety of components, including a flexible-design multi-tasking controller, two modular multi-axis robots, and a conveyor unit that can sort and move components, as well as manipulate them. This machine enables the assembly of complex boards with high precision. The controller at the heart of the tool comes with an intuitive and interactive graphical user interface, providing a robust set of programming tools and command functions to allow for precise adjustment of the process. The robots are capable of linear movements for picking up and placing components, and a rotary indexer is also available to allow for positioning of objects in three-dimensional space. The conveyor asset enables rapid transport of components and boards between stations, and makes sorting operations fully automated. HSP 4796R doesn't just support standard board assembly; it also offers a range of supporting functions, including optical alignment, component recognition, and barcode labeling. In addition, the model features double-deck technology, enabling two stages of operations to run concurrently. This gives the equipment a measure of flexibility that allows for the application of complex assembly sequences. Overall, UNIVERSAL HSP 4796R provides users with an efficient, reliable, and cost-effective solution for high-volume board assembly. With its user-friendly interface, capable controller, and excellent component manipulation capabilities, it is one of the leading process control systems for board assembly and manufacturing.

There are no reviews yet