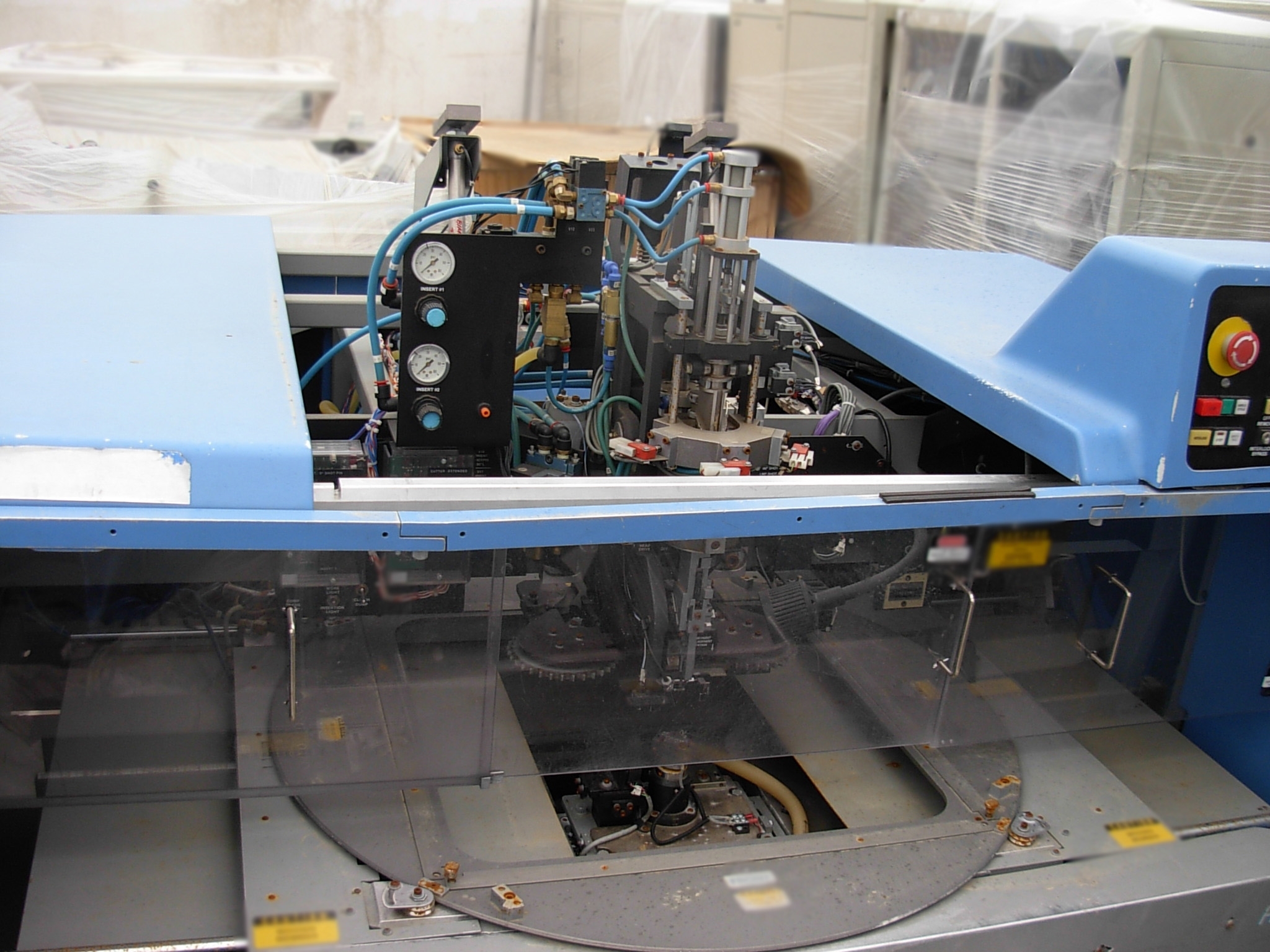

Used UNIVERSAL Radial 5 #9106024 for sale

URL successfully copied!

Tap to zoom

UNIVERSAL Radial 5 is an integrated platform for designing and building PC boards for assembly and manufacturing. It is a comprehensive equipment developed by UNIVERSAL Instruments, Inc. for use in the manufacture of printed circuit boards (PCBs). The system is designed to reduce the time and effort required to build constructive efficient assemblies with minimal waste. The unit is equipped with a precision robotic arm with three interactive and fully automated stations, along with a user-friendly graphical interface. The first station is the pick-and-place station which houses a high-speed, highly accurate gantry robot arm. This station is responsible for transferring components onto the production line. It is equipped with a vision machine to ensure the pinpoint accuracy of parts placement. Once the components are placed, the robot arm automatically moves them to the placements for the second and third stations. At the second station, the components are tested for quality assurance. Quality assurance software helps ensure that all components and components interactions are tested for accuracy and functionality. This helps to minimize potential problems associated with assembly and production. The final station is responsible for the welding of the components onto the board. This is accomplished using a CNC-driven laser welding tool that is capable of welding from one layer to the next, creating a precise and reliable assembly. Radial 5 allows manufacturers to rapidly design and make PCB assemblies in a streamlined and efficient manner. With a combination of hardware and software, the asset is able to incorporate parts into the robot arm, bring them to their proper placements, test and weld them, creating quality assemblies faster. This speeds up the process of production and helps reduce waste and cost associated with producing PCBs. Overall, UNIVERSAL Radial 5 is a comprehensive and streamlined model that offers a variety of features that makes it a viable option for PCB manufacturing and assembly. It provides precision, accuracy, and speed in the production process and it is easy to use. This makes it an ideal solution for anyone looking for an efficient and effective equipment for PCB assembly and manufacturing.

There are no reviews yet