Used Various Line #190064 for sale

URL successfully copied!

Tap to zoom

ID: 190064

Line of Equipment

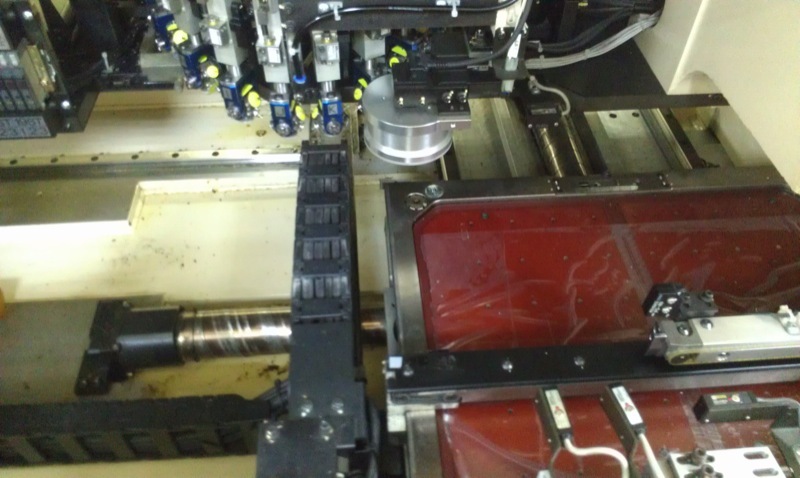

DEK Horizon O2i Printer, 2006 vintage

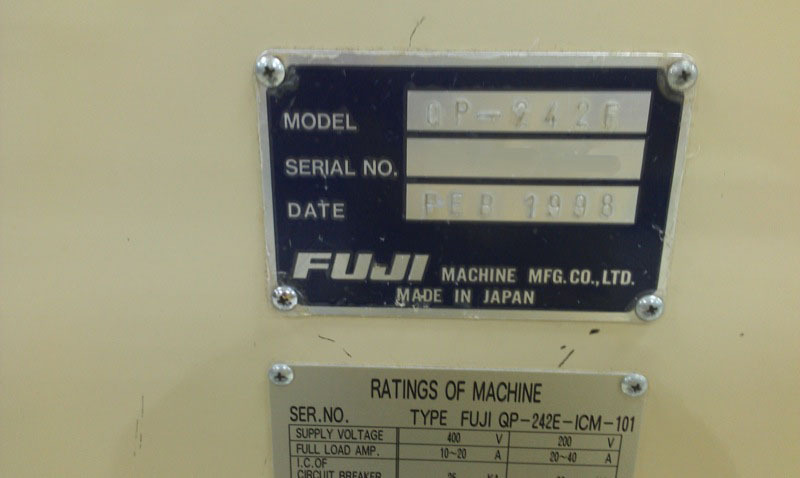

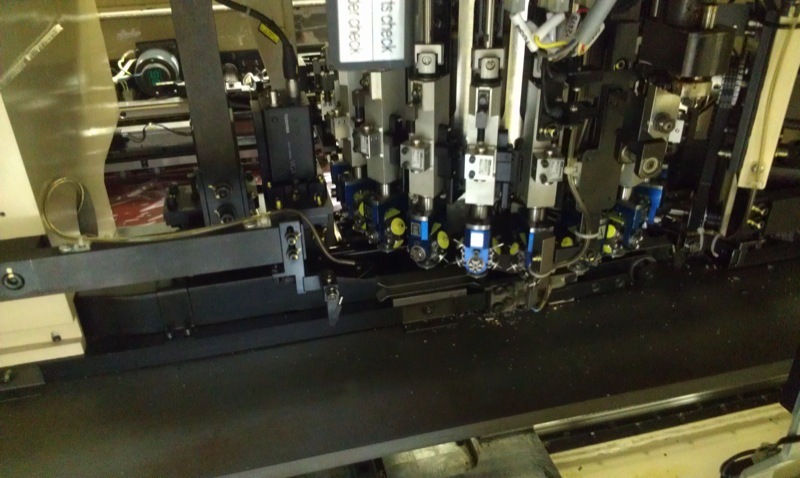

FUJI CP642 Mounter, 1998 vintage

FUJI QP242E Mounter, 1998 vintage

HELLER 1800EXL Oven (N2 system), 1999 vintage.

Various Line is an advanced and comprehensive pc board assembly and manufacturing system that specializes in quick turn-around and cost-effective solutions for a variety of industries. It combines the latest in industry-leading software and hardware technologies to provide high-speed, high-quality assemblies for a wide range of products, including medical devices, consumer electronics, aerospace, and industrial control systems. The system covers all aspects of printed circuit board (PCB) assembly, from part placement to soldering and inspection, to provide the highest quality products and the shortest lead times. At its core, Line offers advanced automated software and hardware solutions for the production, assembly, and inspection of a variety of PCBs. This solution includes pick & place technology, automatic and manual soldering, 3D inspection systems, process optimization tools, and more. The software solutions facilitate job setup, automation control, and quality assurance for a robust and efficient production process. These solutions have been developed over decades to offer a powerful, easy-to-use, and highly customizable solution for each customer's needs. Various Line also includes advanced hardware components to complete the PCB assembly process. Automatic pick & place machines can quickly and accurately pick up, place, and solder components onto the PCB while manual and robotic soldering systems ensure the highest quality solder joints. 3D inspection systems can also be used to verify that all components are placed accurately and that there are no soldering defects or electrical shorts. These solutions are designed to reduce labor costs, improve throughput, and ensure the highest quality products without sacrificing reliability. Line also offers innovative solutions to reduce waste, energy, and costs. Its advanced environmental management systems are designed to optimize energy use and reduce the environmental impact of PCB assembly. Its software solutions also allow for efficient material management to ensure that components and materials are only used when necessary, reducing waste and cost. Overall, Various Line is a comprehensive and comprehensive solution for PCB assembly and manufacturing. Its advanced software and hardware solutions provide a flexible, fast, and high-quality production process for a variety of industries. Its environmental management systems and material management solutions also support a responsible, environmentally friendly, and cost-effective production process. With Line system, customers are assured of the highest quality products, the shortest lead times, and the most reliable and cost-effective solutions.

There are no reviews yet