Used Various Line #9062048 for sale

URL successfully copied!

Tap to zoom

ID: 9062048

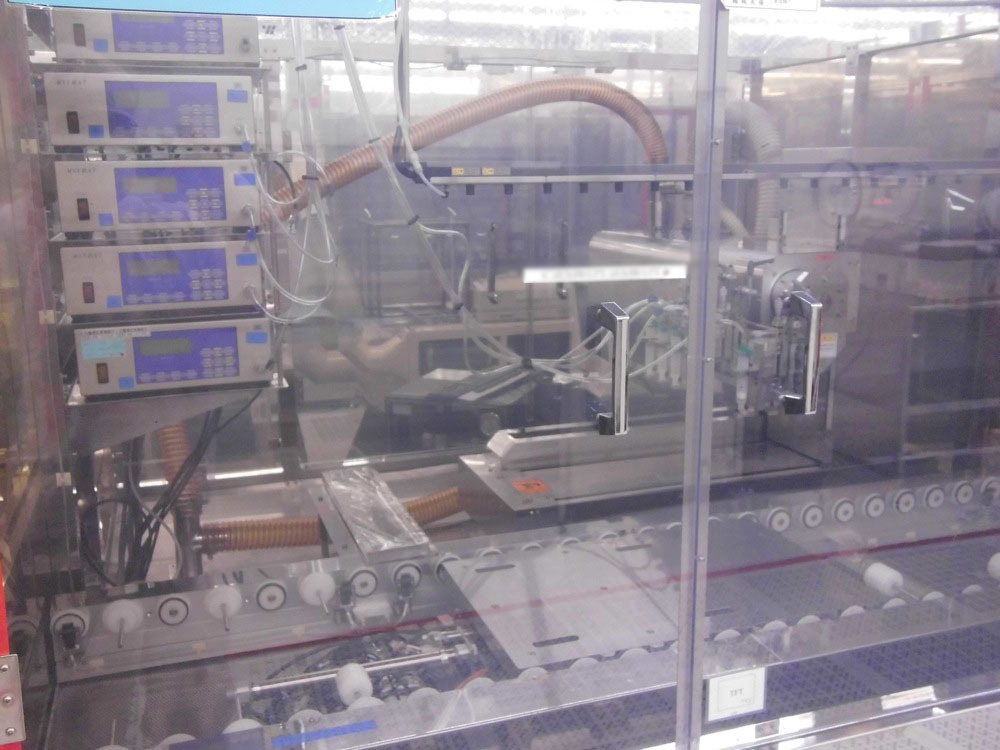

Line of equipment:

Substrate Cleaner EVATECH PVI-16930-OR

PI COATER/PRE BAKE NAKAN A-45

PI MAIN CURE: gold leaf H/P18 furnace, furnace cooled 4 NAKAN

RUBBING MACHINE FUJIOKA FS-45RU-ALL

RUBBING MACHINE FUJIOKA FS-45RU-ALL

AFTER RUBBING CLEANER TESCOM TA-9502

EPOXY PRINTER / PREBAKE NEWLONG LZ-9518

SPACER SPRAYER/DRY CLEANER NISSIN TA-9503

AG PASTE DISPENSER NEWLONG LZ-9518 DIS

PANEL ALIGNER ShinEtsu SE-LCAS-T

(2) NISSHIN SPACER SPRAYER DAIHEN SPR-90

(2) EVATECH Substrate Cleaner L/D SANKY SC3000.

Various Line is a PC board assembly and manufacturing equipment that enables customers to quickly and easily produce assemblies of high-quality printed circuit boards. This system provides a wide range of production flexibility, allowing customers to quickly switch from one production task to another. Line includes a comprehensive workflow software unit that helps customers manage all their production data. This includes tracking data for material usage, production processes, inventory cost, and customer requirements. The software also features customisable views to provide a unique and customised experience for each customer. The PC board assembly Various Line utilises cutting-edge technologies to increase productivity. Tooling jigs, carrier pins, and fixtures are made from high-grade materials to ensure that the produced products are of superior quality. Various fixturing systems help increase throughput and maintain accuracy during the production process. Additionally, custom robot arms are used to automate the printing, assembly, and repair processes. The machine utilises a highly reliable transformer assembly process to quickly complete large batches of orders. Heat-resistant equipment and fast frequency tuners help maintain a consistent output level for assembling large batches of transformers on the PC board assembly Line. The Printed Circuit Board Manufacturing process Various Line is designed to be fully automated, reducing the need for manual intervention. Automated compatibility testing helps ensure that all the components are functioning together correctly. The production regulator provides a self-regulating environment that is capable of maintaining consistent temperatures and levels of pressure. Process analysis tools are also provided to ensure customers get the best value from the tool. This includes quality metrics such as frequency scans, temperature rating asset, and model operational notes. Additionally, the equipment provides an advanced analysis suite that lets customers further analyse the effect of their designing. Line produced PC board products have error detection capabilities that ensure that any errors are detected and fixed before the final assembly. Error correction techniques are used to further improve the overall reliability and durability of the products. The system also features a repair station for repairing and improving any assemblies that may have multiple defects. Overall, Various Line is an advanced PC board assembly and manufacturing unit that offers a wide range of benefits to customers. Its advanced technology, automated processes, and quality analysis tools help customers save time and cost. Additionally, its innovative design features and repair station reduce the risk of errors and increase product reliability.

There are no reviews yet