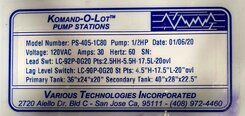

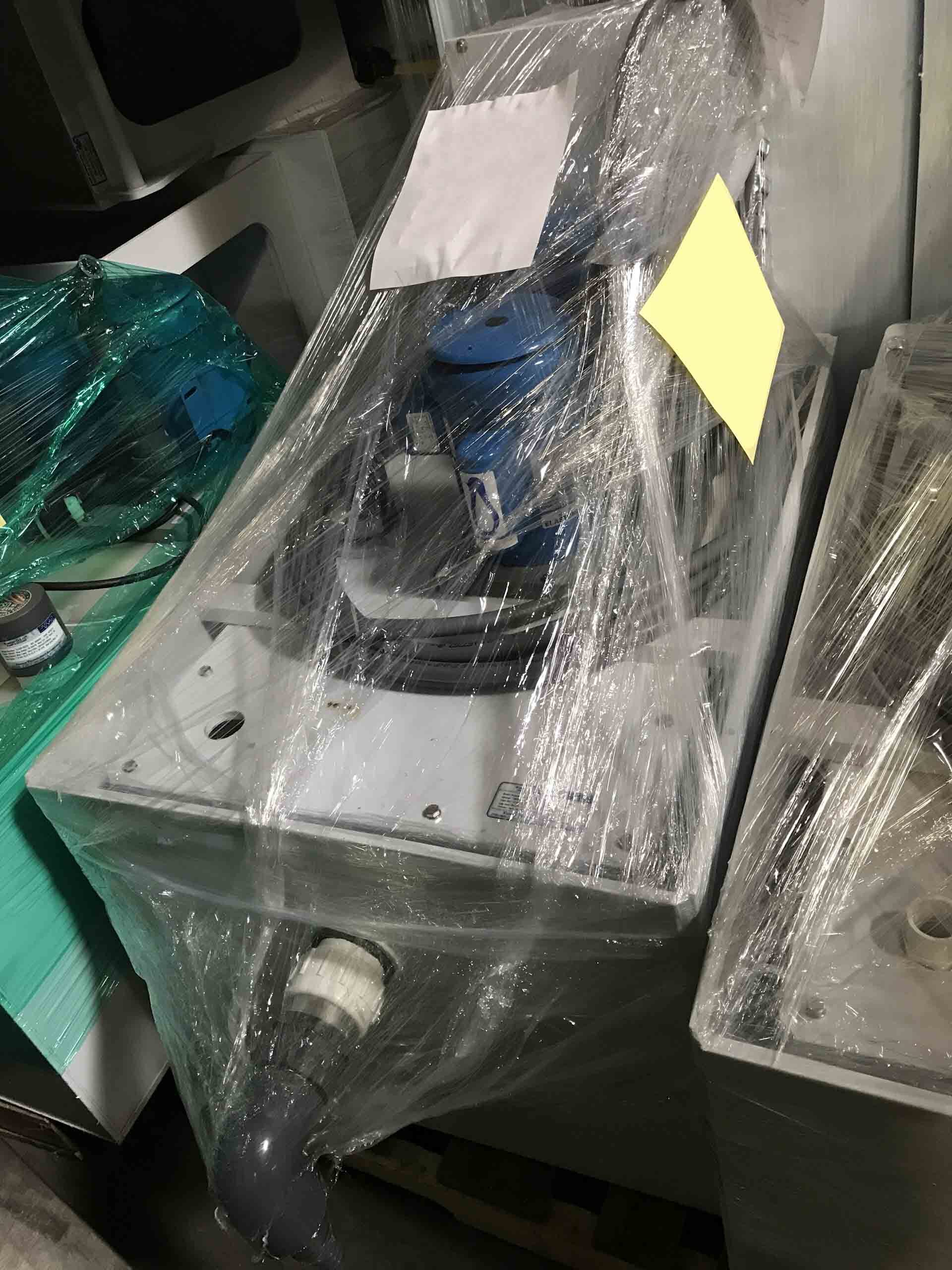

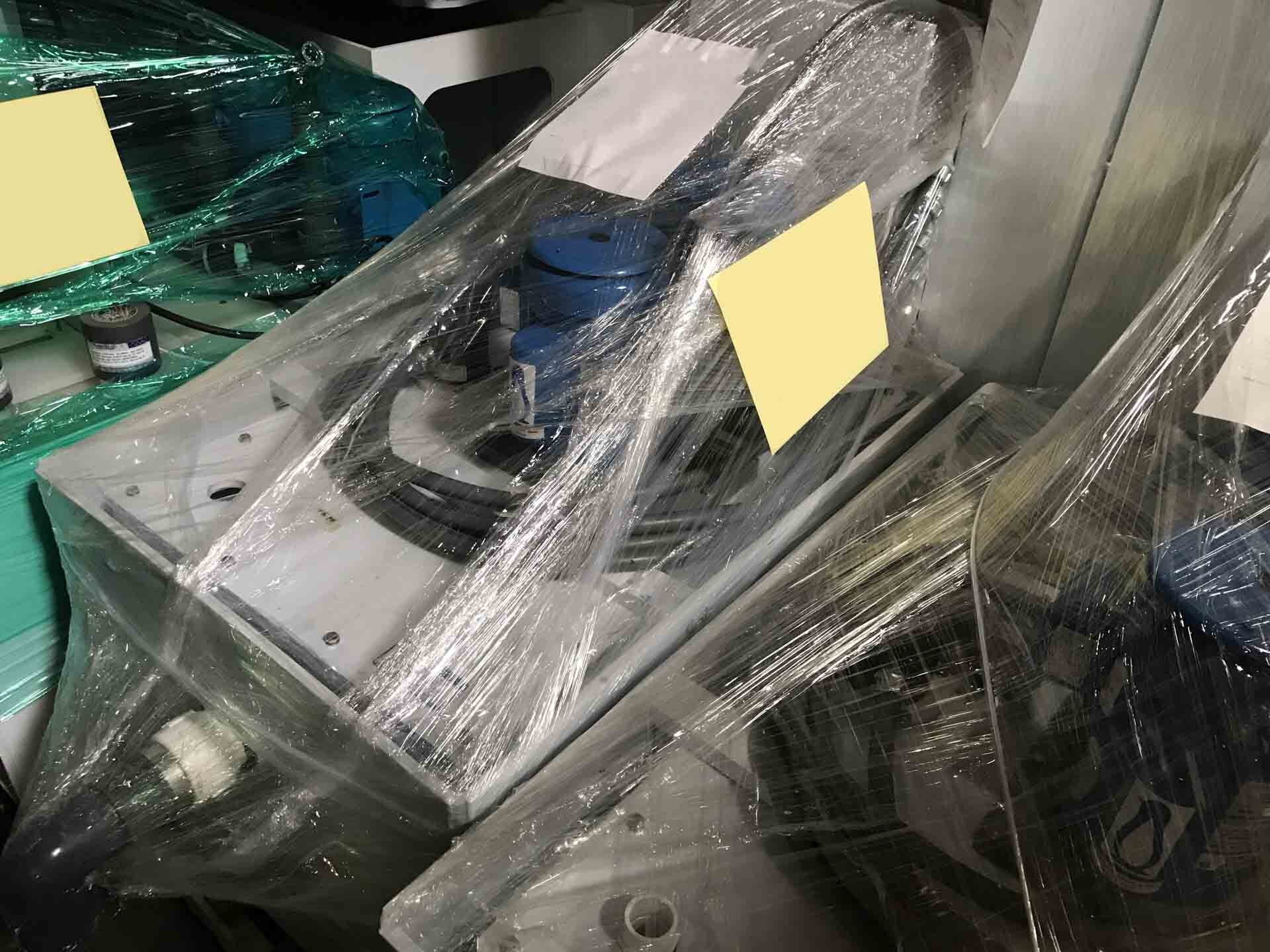

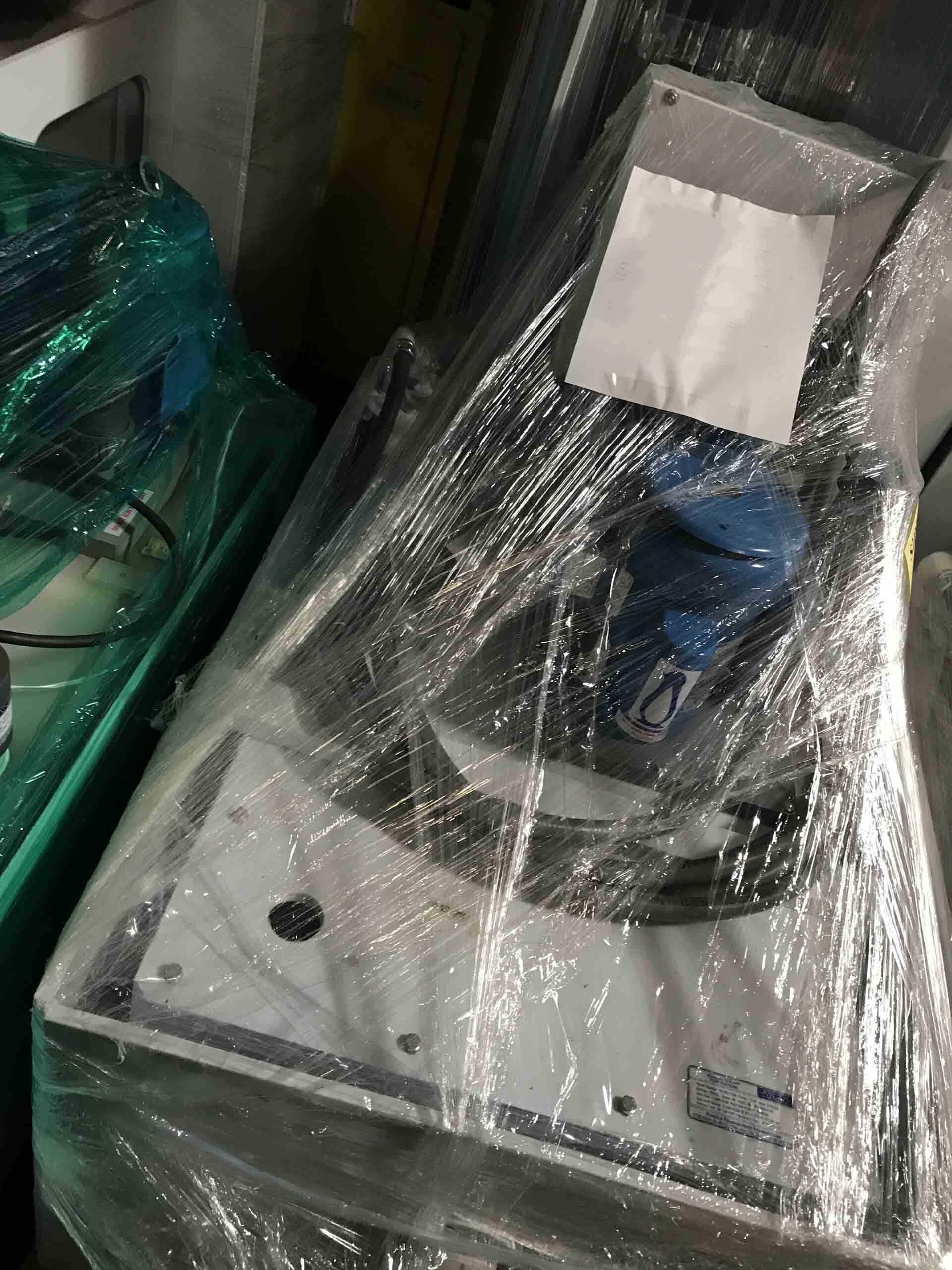

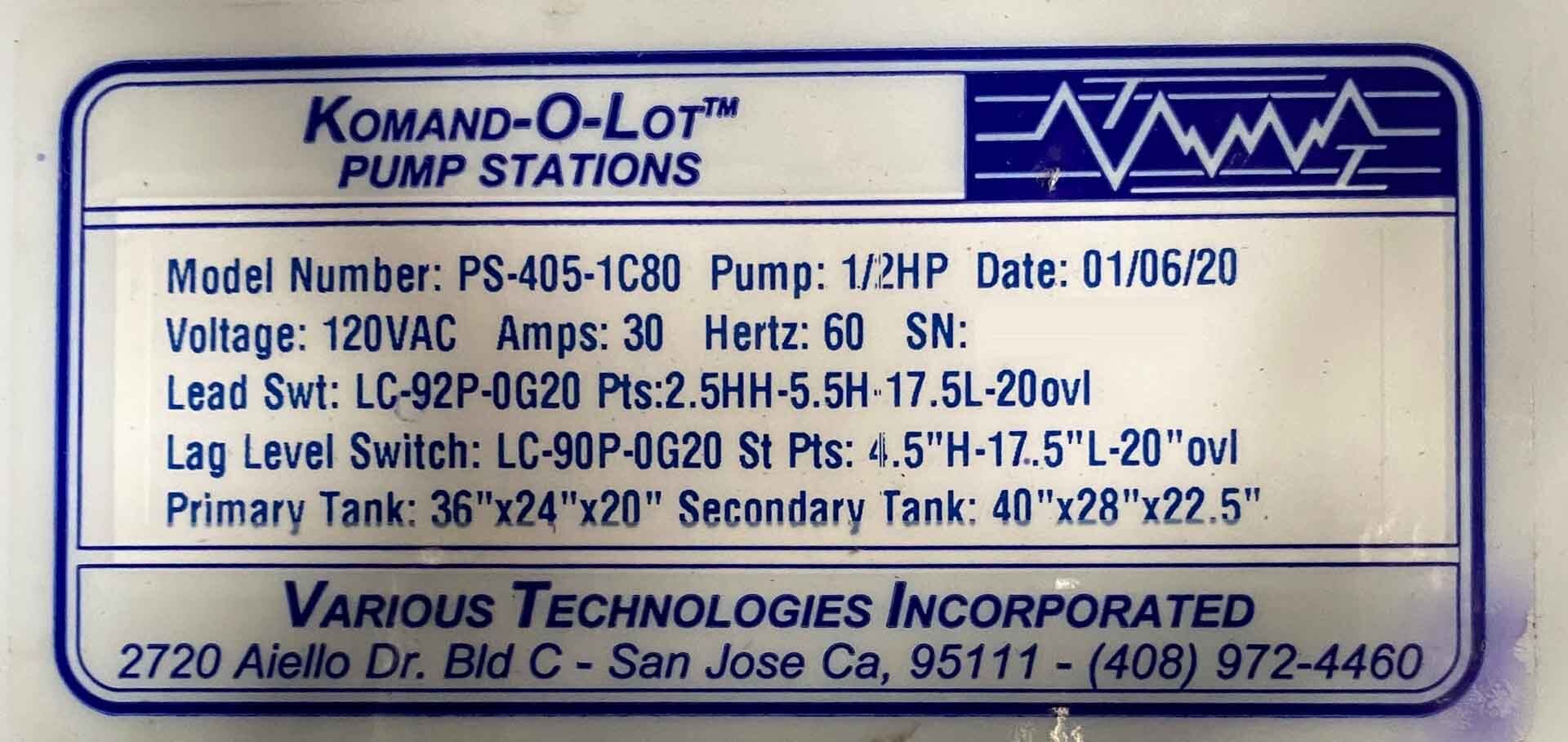

Used VARIOUS TECHNOLOGIES PS-405-1C80 #293597619 for sale

URL successfully copied!

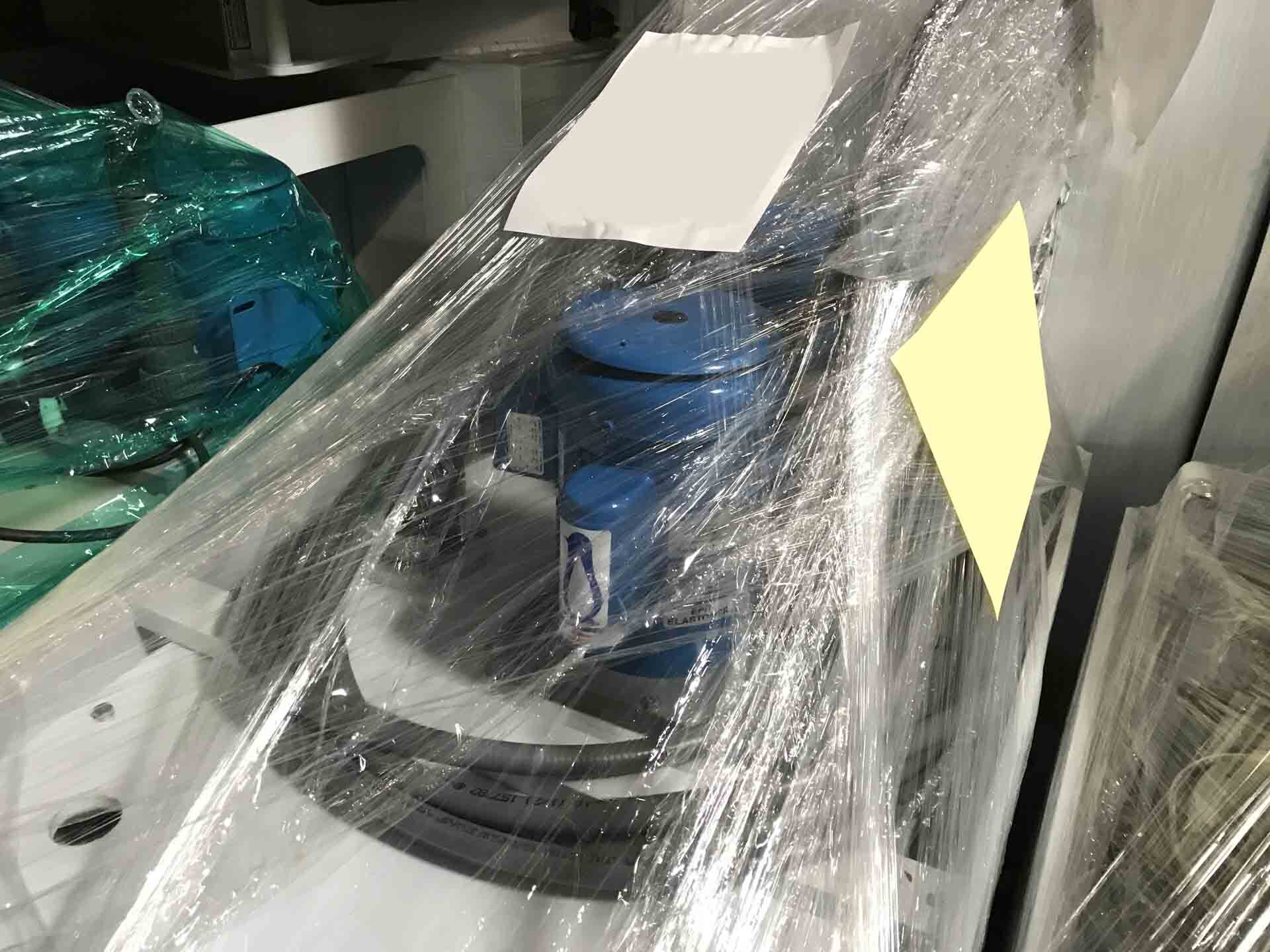

Tap to zoom

VARIOUS TECHNOLOGIES PS-405-1C80 PC Board Assembly and Manufacturing Equipment is a powerful, flexible and reliable manufacturing solution for high-volume production of printed circuit boards (PCBs). The system is designed to provide maximum efficiency, flexibility and cost savings for high-volume PCB assembly and manufacturing. PS-405-1C80 PC Board Assembly and Manufacturing unit features a modular design, allowing users to configure the machine to best suit their needs. The tool is based on a four-axis CNC machine, allowing for automated routing of component mounting and component insertion. This includes precision placement of component leads. The asset also includes an Image Recognition and Imaging Model (IRIS) to visually confirm component placement. The equipment includes a fully automated component placement system, capable of dispensing paste, screening and component placement. The unit is also capable of handling automated optical inspection and flying probe testing, to ensure accuracy and quality. It also includes automated soldering and reflow. A fully automated component mark storage and retrieval machine is also included. The tool can be configured with a variety of component feeders, stencil printers, and placement heads for optimal performance and flexibility. Additionally, the asset supports the creation of compound stencils, to simplify printing and component placement of complex designs. The model is designed to run both manual and automatic programs and can be integrated with other technologies, including material handling systems and LabVIEW Control Systems. It also supports data collection and analysis, as well as basic process control. In addition, the equipment can be used to program and run automated test equipment, to ensure maximum product quality. Overall, VARIOUS TECHNOLOGIES PS-405-1C80 is an innovative solution for printed circuit board assembly and manufacturing. The system offers a modular design, precision component placement and automated soldering and reflow processes, to ensure high-quality and cost-effective production of printed circuit boards. The unit is well-suited for high-volume production applications requiring high degrees of accuracy and precision.

There are no reviews yet