Used VI TECHNOLOGY 4000L #9118020 for sale

URL successfully copied!

Tap to zoom

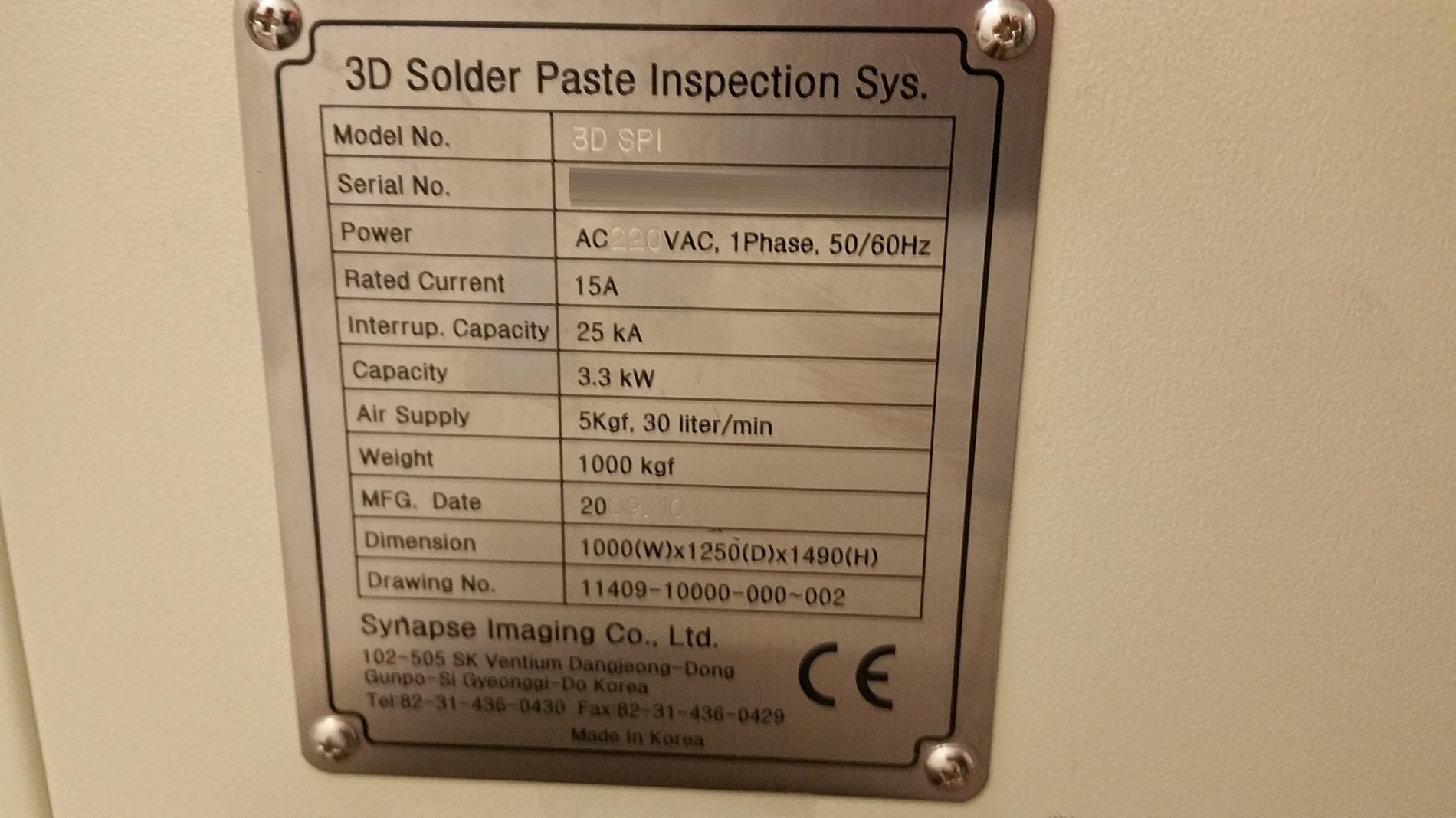

ID: 9118020

Vintage: 2009

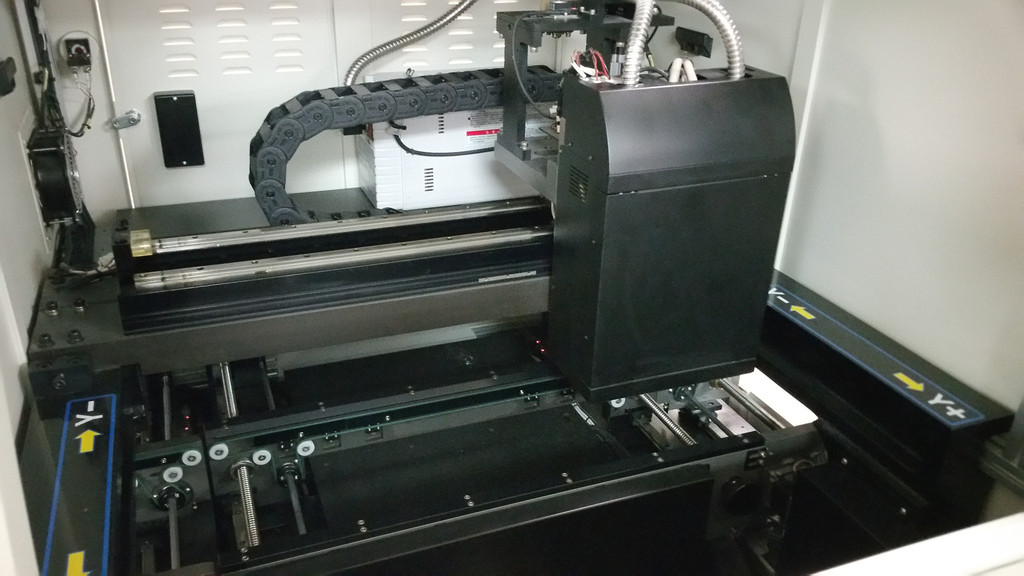

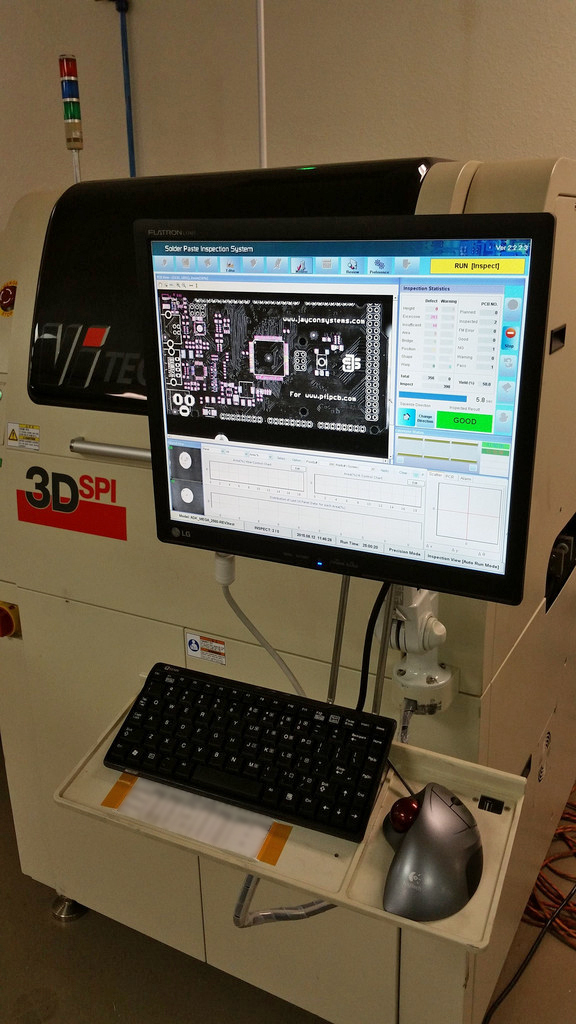

3D SPI System

Maximum board dimensions: 510 [20] x 460 [18]

Board thickness (minimum to maximum): 0.4 to 5 mm [0.01 to 0.19]

Clearance under camera: 25 [0.98]

Clearance under board: 25 [0.98]

Clamping system edge: 3 [0.12]

PCB warpage Maximum: ± 3.5 [0.13]

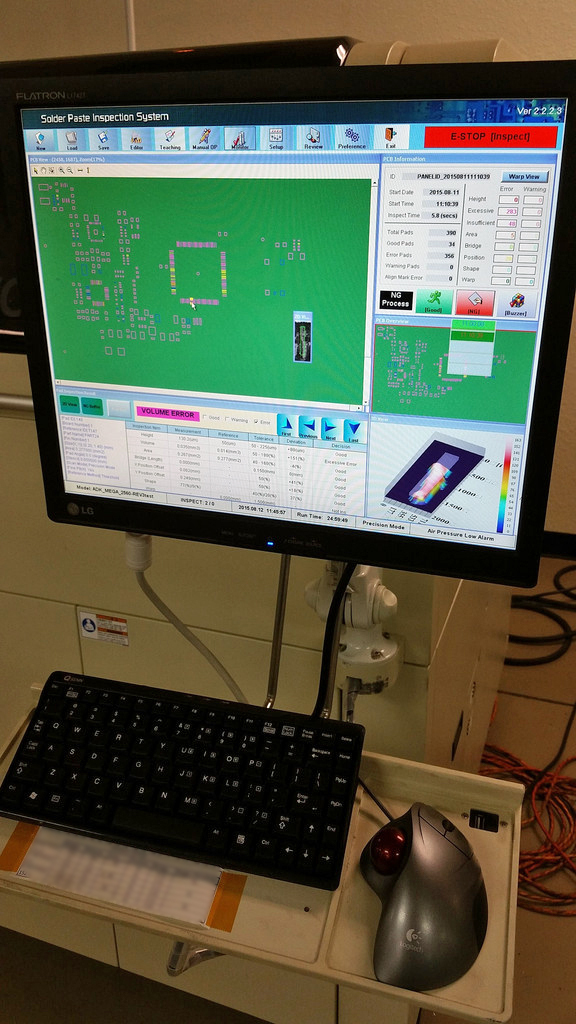

System accuracy and repeatability (measurement at 21°C ±- 1°C)

Measurement repeatability (3 s)

Height: < 1.5 µm at standard certification target

Volume: < 2 % at standard certification target

Measurement accuracy Height: < 3 µm at standard certification target

Measurement resolution: Height 0.1 µm

Area: 20 µm

% Gage R&R: < 10%

Average inspection speed

Inspection speed: 20 cm2/sec (without shadow effect)

Inspection items: Height, volume, shape, area, bridge, position

Measurable object size Length: 160 - 30 000 µm

Height: 50 ~ 500 µm

Power: AC 220 V, 22 A, 50/60 Hz

2009 vintage.

VI TECHNOLOGY 4000L is a high-performance pc board assembly and manufacturing equipment. It utilizes a variety of advanced technologies to provide precise and reliable automated manufacturing processes. With its high degree of modularity, flexibility, and scalability, 4000L is capable of performing many different tasks, including surface mount technology (SMT) assembly, wave and dip soldering, selective soldering, component identification, and optical inspection. VI TECHNOLOGY 4000L has a highly-configurable hardware platform and software interface, allowing it to be customized to a particular workflow and manufacturing requirements. It features a graphical user interface, which is designed to simplify operation by eliminating the need for a detailed knowledge of complex manufacturing processes. 4000L is equipped with advanced and accurate assembly capabilities. Its advanced 3D vision system and closed-loop feeder can precisely detect components on the printed circuit boards (PCBs) and accurately place them in the proper place. It is able to identify a wide range of components, including resistors, capacitors, connectors, and IC packages. This allows precise and reliable assembly processes to be completed quickly and with minimal errors. VI TECHNOLOGY 4000L also features an integrated optical inspection unit that provides real-time imaging of the assembly process. This ensures that the components have been correctly placed and that there are no defects in the finished product. Finally, 4000L is an incredibly reliable machine. Its modular architecture and robust design allow it to be used for long periods of time without needing to be serviced or maintained, while its reliable processes help to minimize downtime and reduce the costs associated with repairs. In conclusion, VI TECHNOLOGY 4000L is an advanced PC board assembly and manufacturing tool that can provide high-quality results with a minimal amount of time and effort. With its advanced features and flexibility, it offers a powerful yet cost-effective solution for any manufacturing requirement.

There are no reviews yet