Used VI TECHNOLOGY VI 3000 II #9064259 for sale

URL successfully copied!

Tap to zoom

ID: 9064259

Vintage: 2006

Automatic Optical Inspection (AOI) system

Single lane

Operating system: Windows 2000

Manuals included

Voltage: 115 V

2006 vintage.

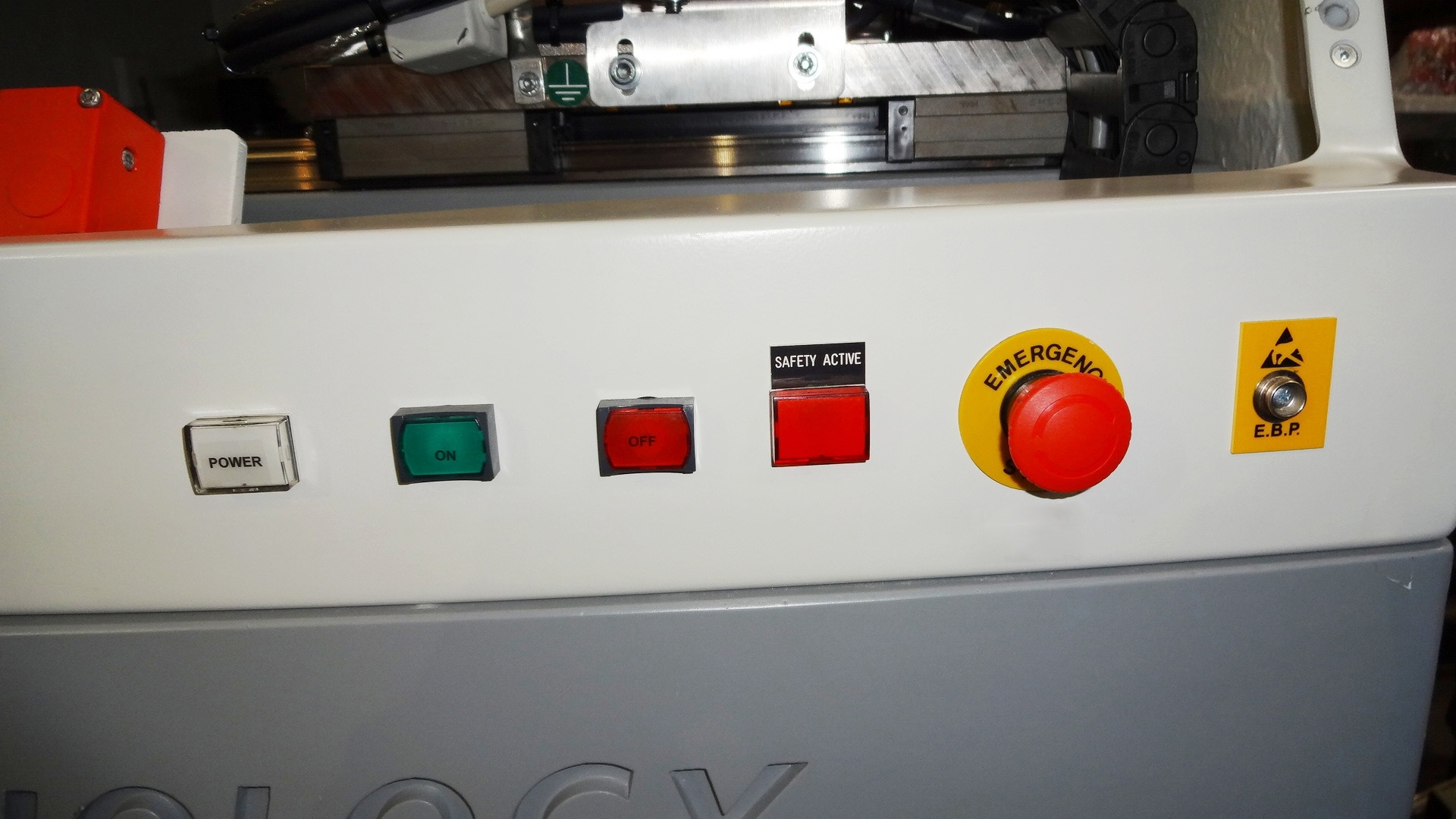

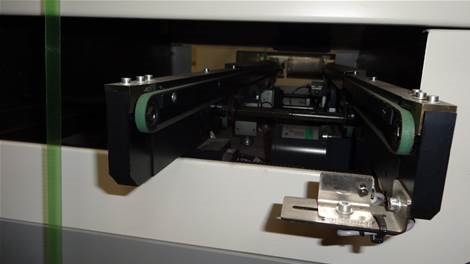

VI TECHNOLOGY VI 3000 II is a complete board assembly and manufacturing equipment designed for lean mass production of varied products including Base Boards (BBs), Feature Boards (FBs), Miniature Boards (MBs), Panelized Boards (PBs), and Multi-Layer Boards (MLBs). With its advanced and high-speed process capabilities, VI 3000 II facilitates high-precision placement and assembly operations with reduced material consumption, avoidance of waste material, and ultra-low reject rates. The comprehensive system has a wide-ranging 360-panel capacity and is dedicated to significantly improving efficiency. With automated processing that lets users customize their production lines to match their demand, it supports multiple production lines operating simultaneously. The unit offers flexible networking capabilities as well as real-time monitoring and reporting to ensure precise and cost-efficient operations. VI TECHNOLOGY VI 3000 II's capability to reliably handle large board sizes as well as complex panel design is made possible by its advanced vision machine and industry-leading insertion technology. It offers a 24-part registering station for consistent high-accuracy placement with its array of resources such as the automatic feeder selection, the raw material uploading station, and the tray/pocket selector. What sets VI 3000 II apart is its modular built, which aids in the easy integration with any production line thanks to custom configurations. Furthermore, the tool's user-friendly operating panel allows users to control and supervise their production processes. VI TECHNOLOGY VI 3000 II offers continuous improvement in cycle times, productivity, and cost savings for complete board assembly and manufacturing. With its cutting-edge technology, it optimizes, simplifies, and speeds up the board manufacturing and assembly process while minimizing material waste.

There are no reviews yet