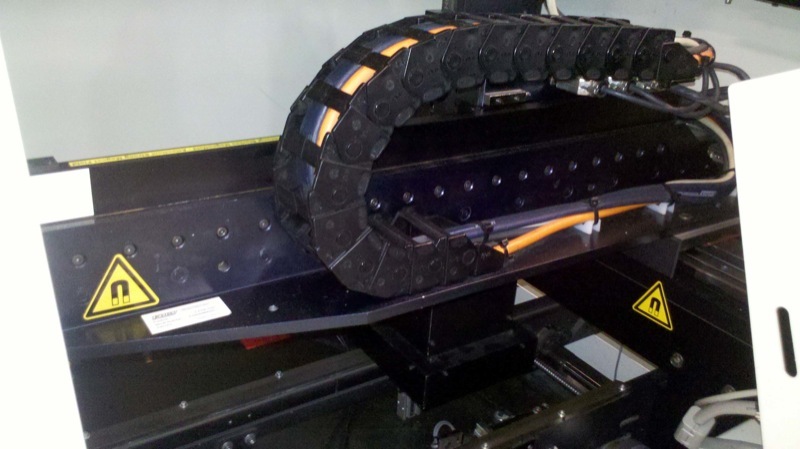

Used VI TECHNOLOGY VI 3000 #9004092 for sale

URL successfully copied!

Tap to zoom

ID: 9004092

Vintage: 2002

Automatic Optical Inspection (AOI) system

Cognex 8120 vision board

Teli camera

2002 vintage.

VI TECHNOLOGY VI 3000 is a fully automated pc board assembly and manufacturing equipment designed for low to mid-volume PCB assembly. It is a cost-effective and reliable solution for small to medium production runs requiring rigid component placement accuracy and a high quality output. The system features a complete SMT process capability, with component placement, soldering, optical inspection and testing capabilities. The unit provides a full-scale SMT process line, with two independent component placement heads, along with advanced automatic soldering and vision inspection. It includes a centralized material handling machine, along with a dedicated component storage and feeder tool. The placement heads can place and solder a wide range of components, from 0402 to large QFPs, and BGA, as well as a variety of specialty components. The vision inspection asset offers a semi-automatic or automatic vision inspection mode. It checks for component positioning, polarity, warpage, and solder quality, with automatic pass/fail verification. The model can accurately measure the correct soldering of components, including thermal distortion, heat sink distortion and joint integrity. It is also capable of performing Hi-pot testing, from 500V to 1000V, designed to detect weak solder joints, shorts and open circuits. For total process optimization, the equipment is equipped with a suite of software specifically designed for SMT process control. The system features an advanced graphical interface for easy set-up and programming. It also supports a wide range of data collection and analysis, such as job cost management, statistical process control, and in-process optimization. The unit just requires a small floor-space, with a production capability of up to 1,000 boards/shift. It has an increased productivity rate of up to 15,000 placements/hour, and can be integrated with other processes like wave-soldering. VI TECHNOLOGY VI-3000 is a highly accurate and reliable all-in-one solution for mid-volume PCB assembly operations. It is the perfect combination of accuracy, speed, and reliability for small to medium production runs. It is ideal for the production of complex architectures that require the utmost levels of accuracy and quality assurance.

There are no reviews yet