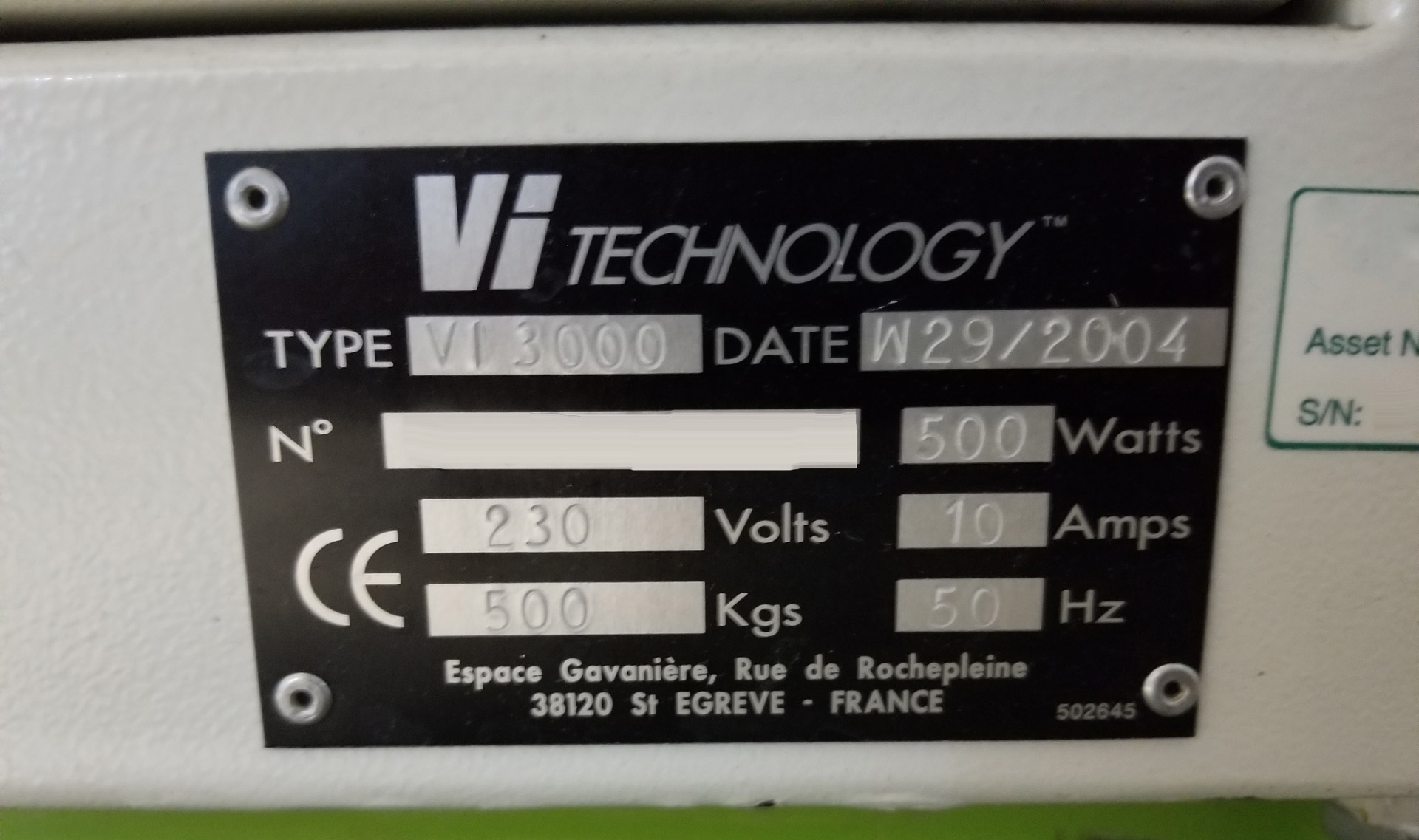

Used VI TECHNOLOGY VI 3000 #9261623 for sale

URL successfully copied!

Tap to zoom

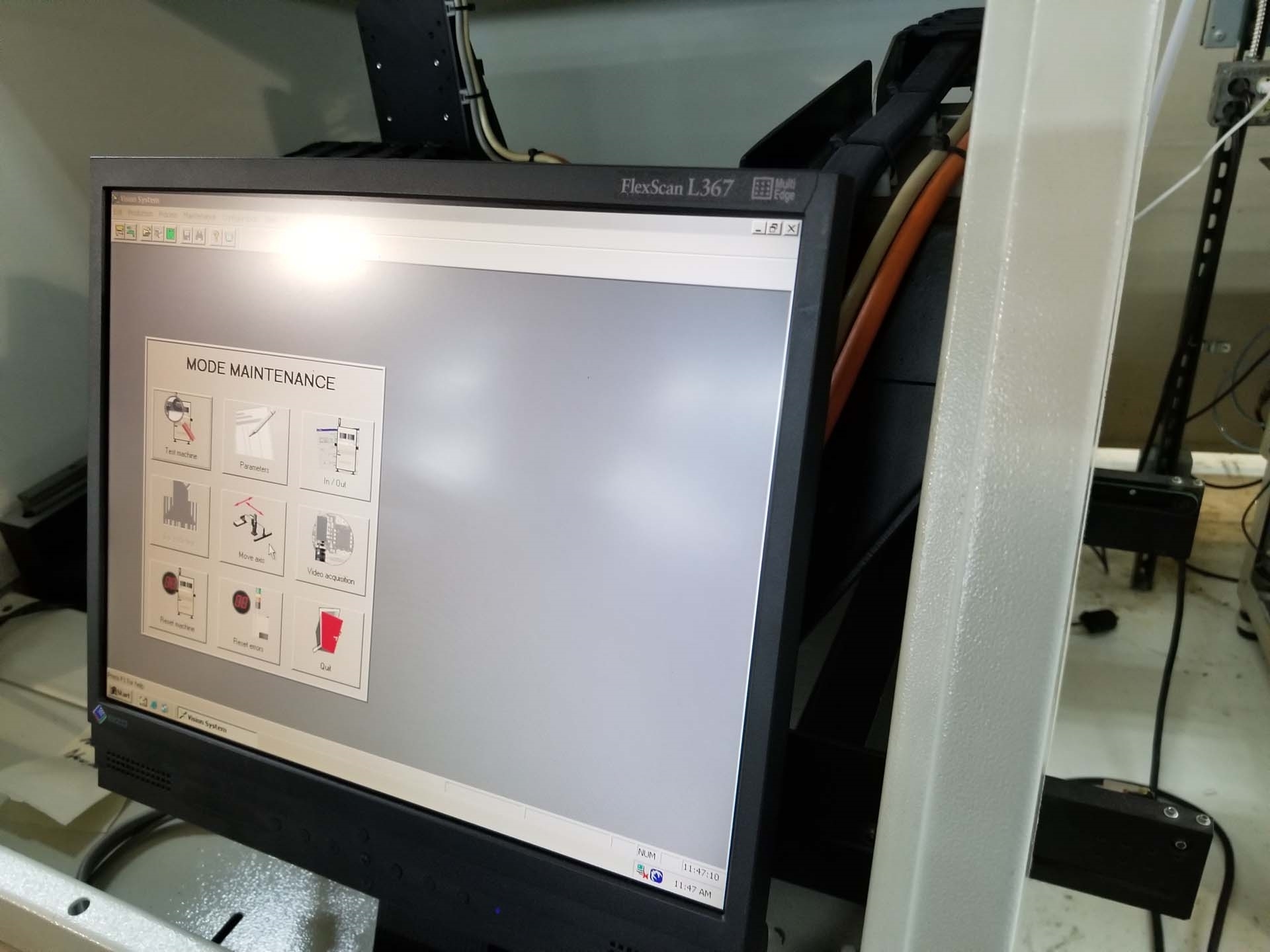

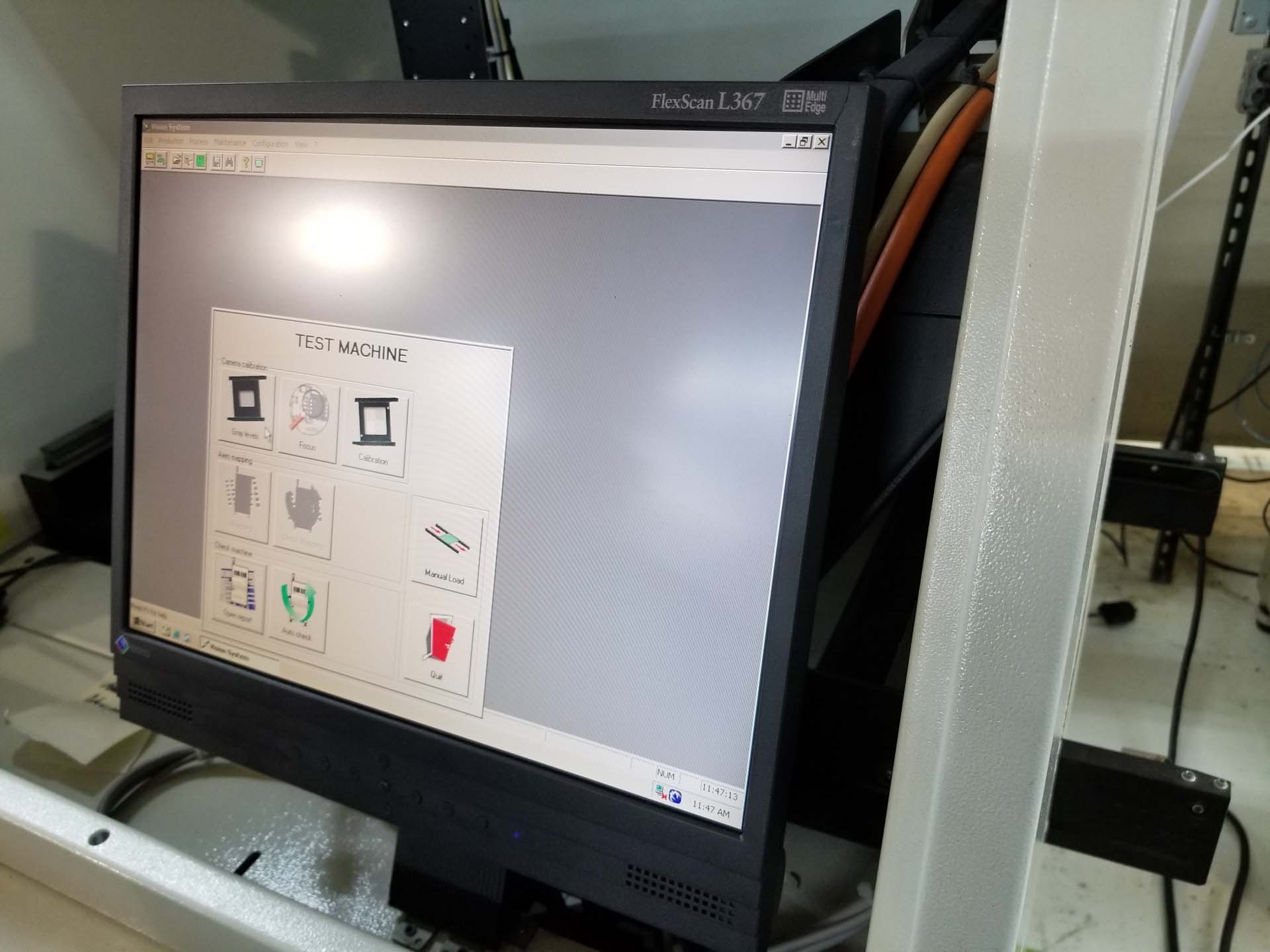

VI TECHNOLOGY VI 3000 is a robust and comprehensive automated PC board assembly and manufacturing equipment. It provides a complete and continuous process from the placement of components to the reflow soldering of the board, without any manual intervention. The system consists of several individual modules including a Pick & Place module, an Inspection module, and two Reflow Ovens. The Pick and Place module uses vision-guided robots to pick components from the feeders and accurately place them onto a PC board. It also verifies the polarity and precise placement of each component before moving to the next component. The Inspection module checks the LED performance, quality, and placement of components after each placement. It also carries out electrical tests on the boards before they are sent on to the next stage of the process. The Reflow Ovens are used to heat-solder the components in place. They feature advanced high-precision temperature controls and provide accurate heating of the components to ensure reliable performance. The unit also provides integrated software for production control and process data analysis. This software allows users to customize the process parameters and monitor the entire process. A variety of auxiliary equipment is available for different process operations such as tempering, flying probe testing, and cleaning. VI TECHNOLOGY VI-3000 provides high levels of performance and reliability. It can process multiple types of components at speeds of up to 800 components per hour and can accommodate boards up to 410mm x 450mm. The machine is also easy to use and maintain, with color display for easy operation and quick troubleshooting. Overall, VI 3000 is a reliable, powerful, and cost-effective PC board assembly and manufacturing tool. It provides a complete and continuous production cycle starting from component placement to soldering. It features innovative and advanced technologies to ensure accurate operation, and its integrated software makes it easy to customize the parameters and monitor the entire process.

There are no reviews yet