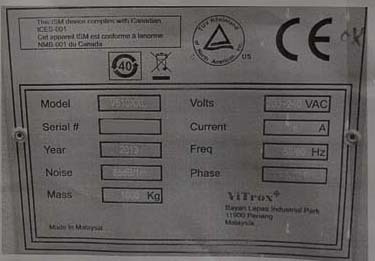

Used VITROX V510 XXL #9170610 for sale

URL successfully copied!

Tap to zoom

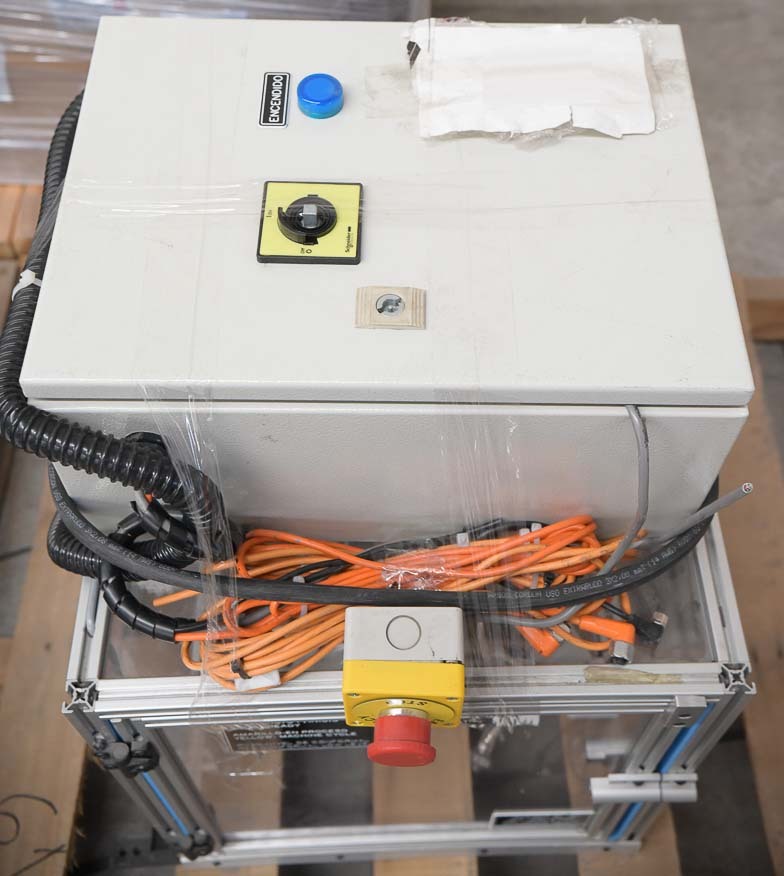

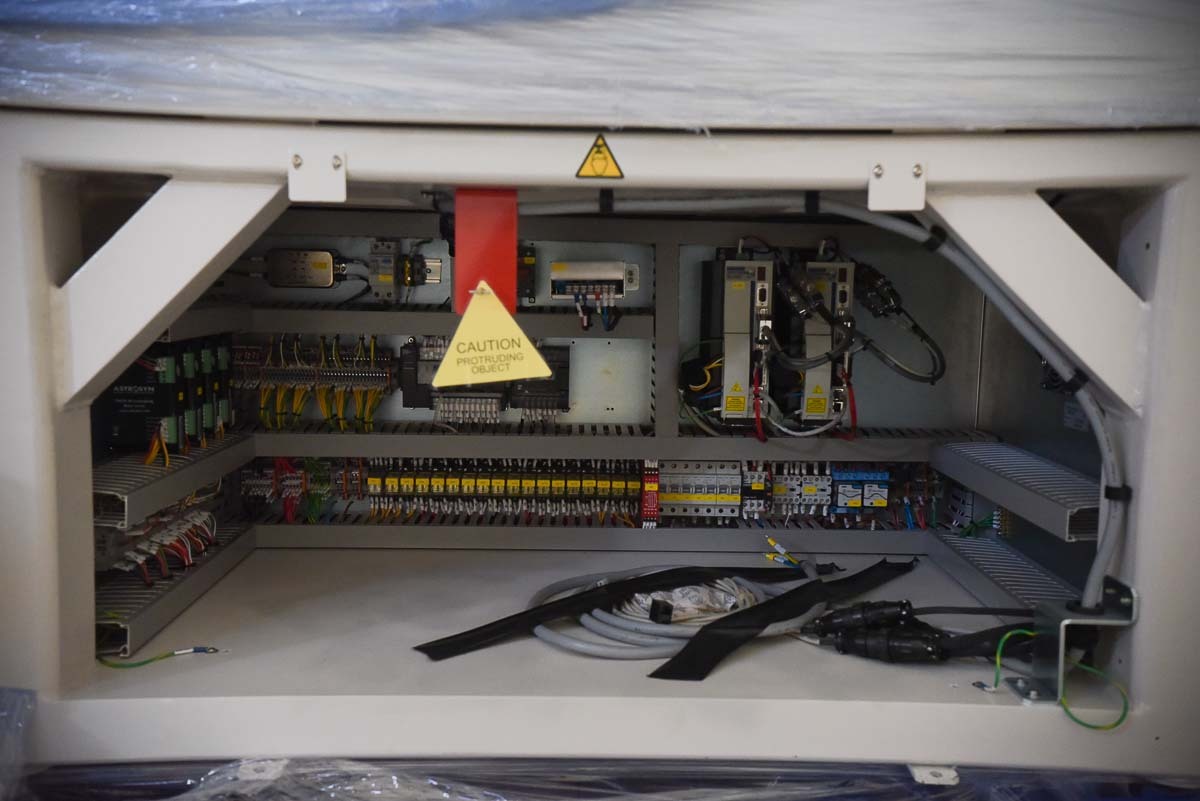

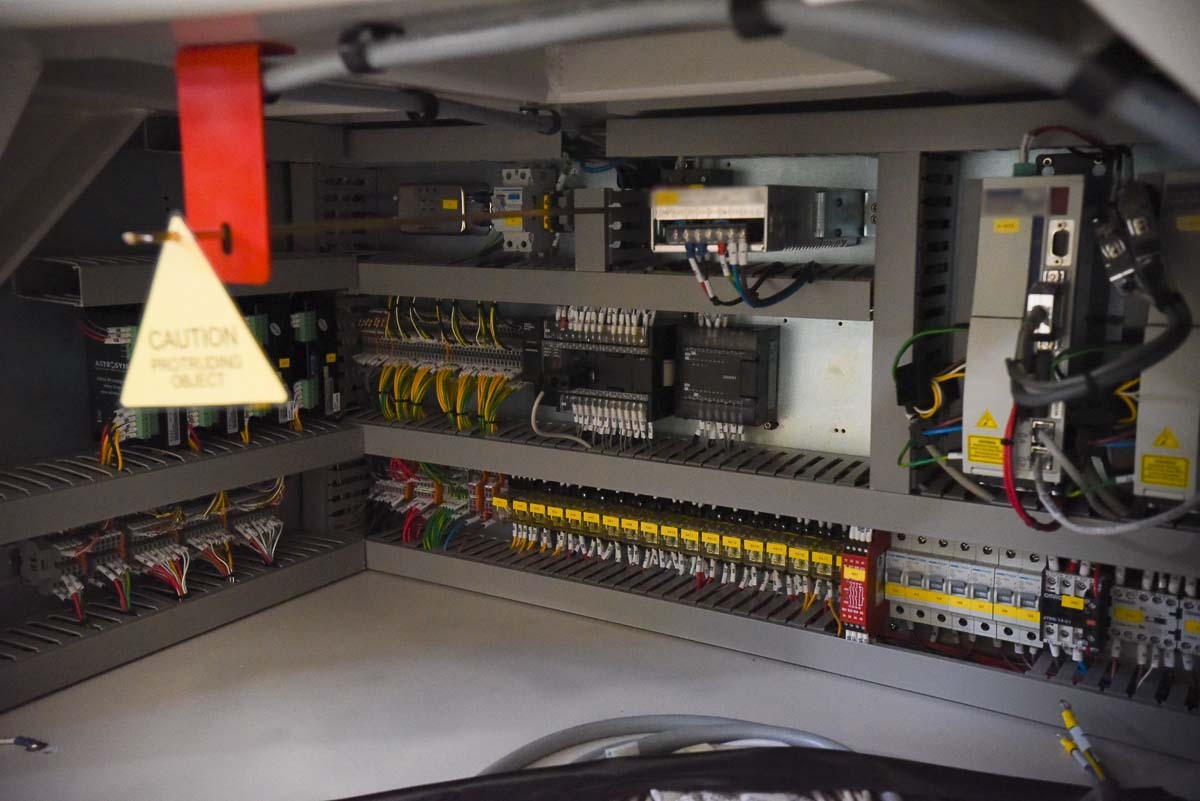

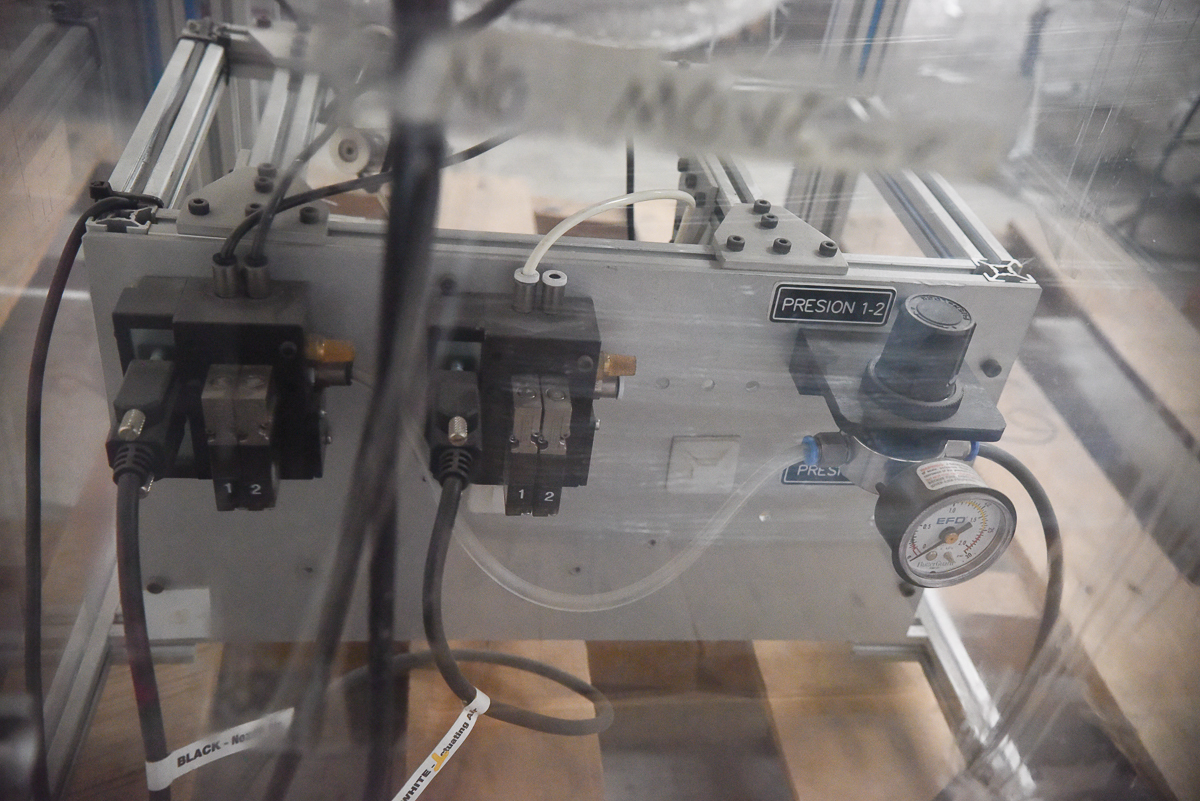

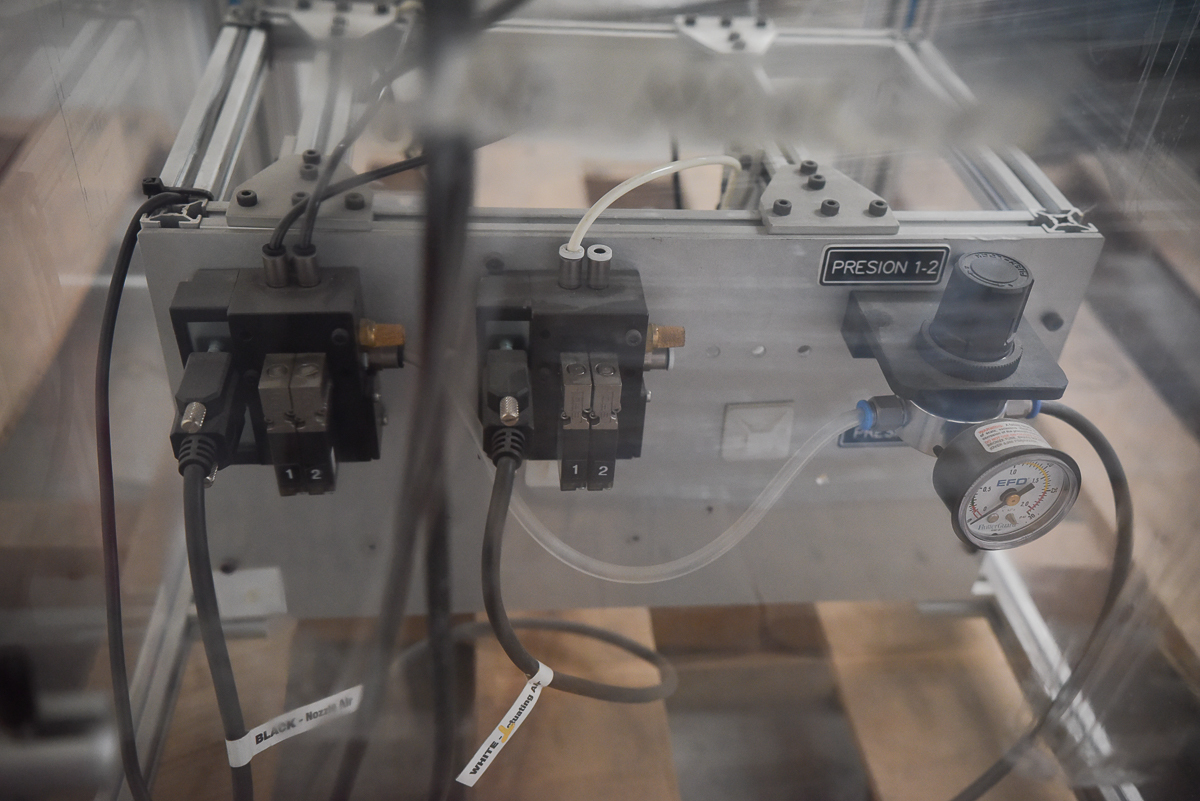

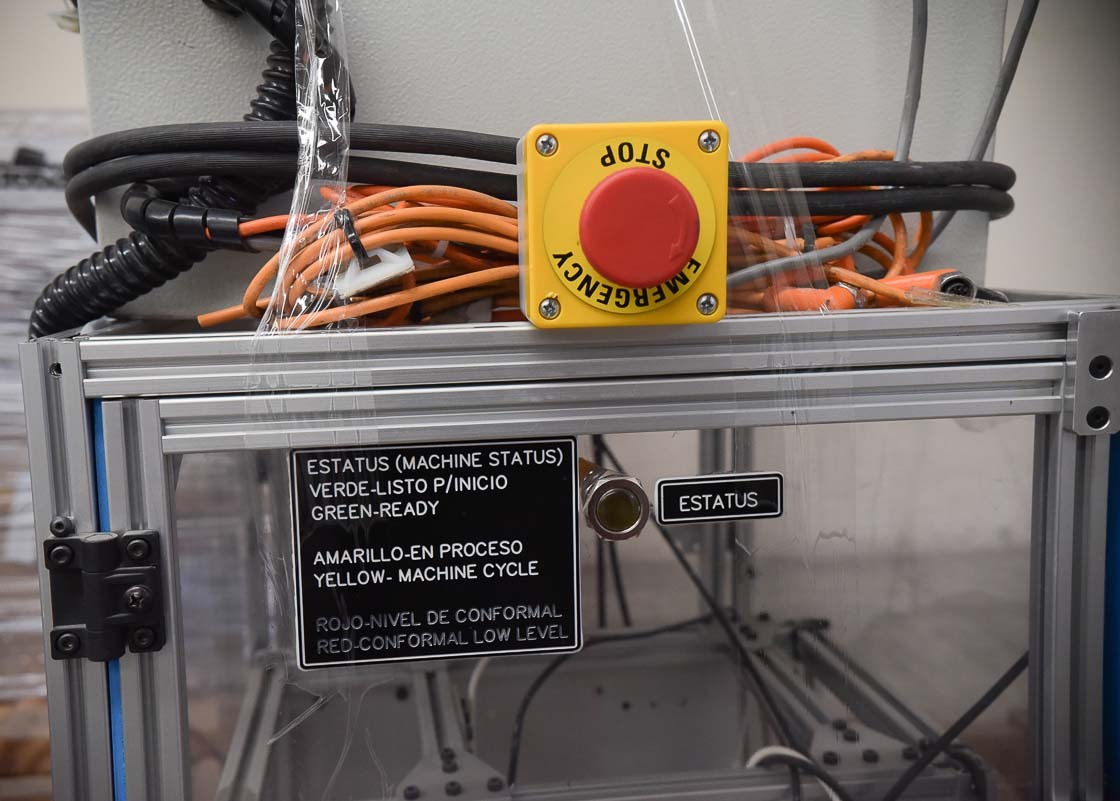

VITROX V510 XXL is a semi-automated board assembly and manufacturing equipment designed to help speed up the production process of surface mount and through-hole-assembly (SMT/THA) environments. This system includes a wide array of components that work together to create a highly accurate and reliable assembly machine. VITROX V510XXL has a tested throughput of over 10,000 components per hour and can handle PCBs up to 610 x 510 mm in size. It's industrial standard components and modular design allows for quick and easy reconfiguration and set-up times. The unit is equipped with a vision-enabled pick-and-place head that can accurately place components with up to 0.2 mm accuracy. It also has an integrated feeder that can accommodate up to 100 reels of components. The feeder is also equipped with a reliable vibratory wheel feeder for odd-shaped components. V510 XXL also has an executive feeder that allows for custom feeder requirements. The machine also comes with a soldering platform that is divided into four individual zones. It also has a board loader that is capable of connecting different boards at once, allowing for quick set-up for multiple configurations. V510XXL also has a line scan inspection tool that is capable of inspecting the board for errors in placement and alignment. The line scan asset also has an image analysis module for better accuracy. In addition, VITROX V510 XXL has an automatic optical control model (AOC) to drive the placement accuracy even further. This equipment will calibrate each axis for perfect precision. It also has vacuum cleaning stations to reduce the amount of smoke and dust created during the manufacturing process. The system also includes a supervisor computer with a user-friendly interface. This will allow the operators to adjust the unit settings directly from the operator's panel. Overall, VITROX V510XXL is designed as a highly reliable and accurate assembly and manufacturing machine, that will help reduce production lead times and reduce manufacturing errors.

There are no reviews yet