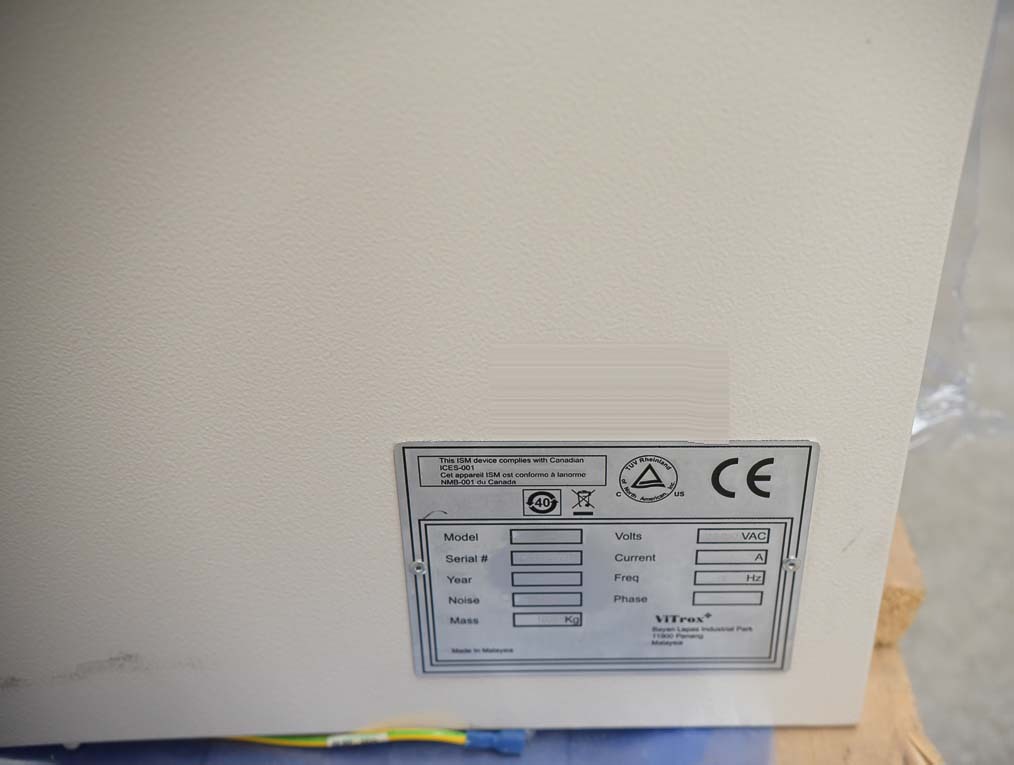

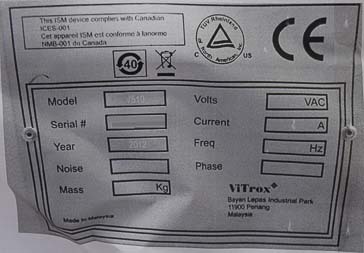

Used VITROX V510 #9170604 for sale

URL successfully copied!

Tap to zoom

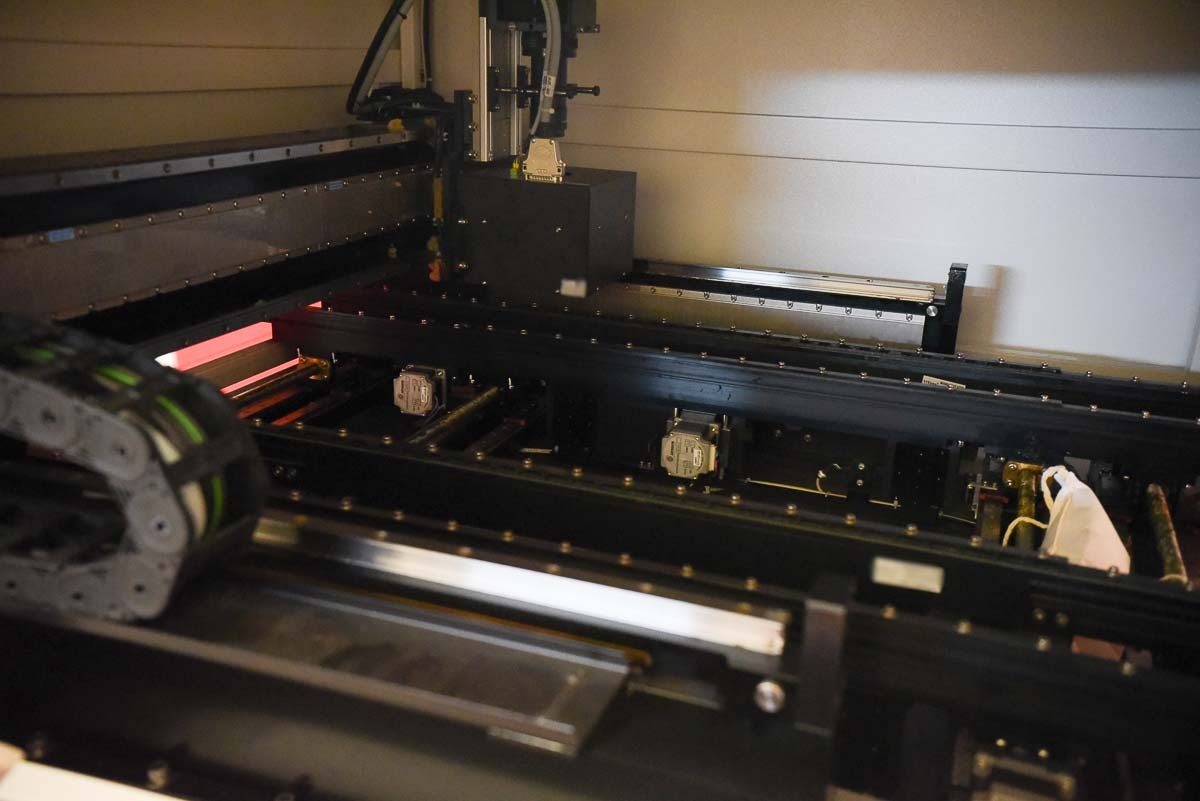

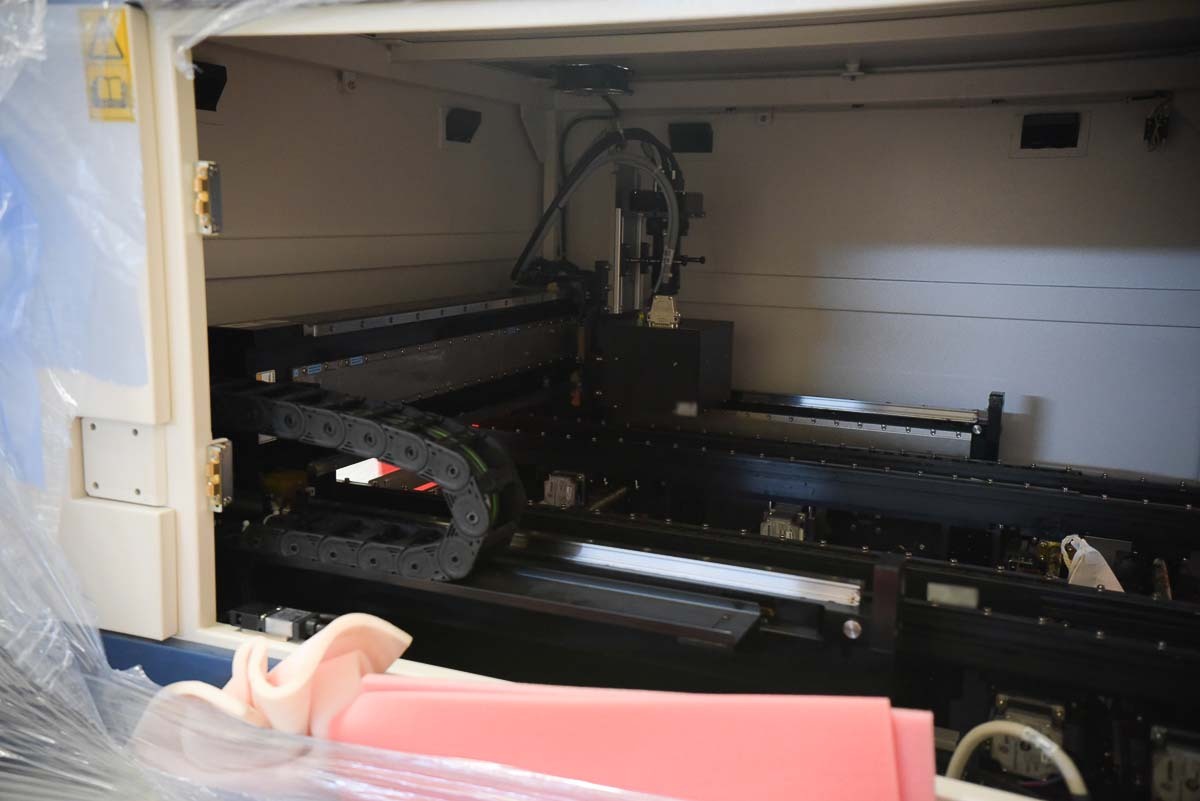

VITROX V510, is a high-resolution, cost-effective, PC board assembly and manufacturing equipment. This system is designed to deliver superior precision and productivity in the automated assembly of Printed Circuit Boards (PCBs). It is an advanced unit that incorporates the latest technology for a reliable and efficient production cycle. VITROX V 510 utilizes an ultra-high-speed vision machine that recognizes patterns on PCBs with great accuracy, coupled with a high-precision placement calibration tool and a multiple z-axis handling technique. All of these aspects allow the asset to place components accurately and reliably regardless of the height or position of the board. This ensures the highest quality assembly of the PCBs. V510 model is capable of supporting a variety of different component sizes and rotations. Its intelligent vision equipment recognizes and handles components with dimensions ranging from small 0402 chip components to large BGA components. In addition, its vision system can detect components with varying degrees of rotation, allowing for precise placement of components. V 510 unit also includes additional features such as multiple vision inspection points to detect incorrect components, misalignment, or missing components at multiple points in the assembly process. This feature helps to reduce potential errors or issues in the manufacturing process by quickly identifying any errors prior to the PCB's completion. The machine is also equipped with an advanced AOI tool that performs additional inspections as well as detailed verifications. This is especially useful for inspecting smaller components and other complex features on the PCBs. Additionally, the asset is capable of storing up to 2000 program patterns, enabling custom vision patterns and fixture set-ups to accommodate various board configurations. VITROX V510 is a powerful and intelligent tool for PCB assembly and manufacturing. Its combination of precision, accuracy, and advanced inspection and scalability capabilities make it an ideal choice for a wide variety of automated assembly applications.

There are no reviews yet