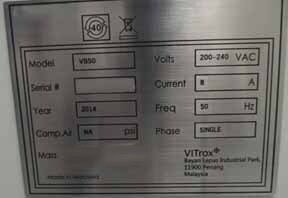

Used VITROX VB50 #9308369 for sale

URL successfully copied!

Tap to zoom

VITROX VB50 PC board assembly and manufacturing equipment is a high-speed SMT component placement and inspection platform designed for the production of high-quality printed circuit boards (PCBs). The system is uniquely capable of performing both single- and dual-sided component placement. VITROX VB 50 is an advanced high-speed vision inspection unit equipped with the latest camera technology and advanced illumination. This provides excellent machine accuracy for both component placement and presoldering defect detection. The tool's semi-automated component placement operation has the ability to pick from 8 or 16 component reels simultaneously. The high-speed gantry motion control allows for the accurate placement of components on PCBs with a high degree of accuracy. VB50 also features an advanced defect detection asset with advanced vision inspection. The model can detect many common PCB defects in real-time, such as missing components, improper component orientation, and insufficient solder connections. VB 50 also has a powerful graphical user interface (GUI) for easy, setup, operation, and maintenance. The intuitive GUI makes programming of the machine a breeze. The GUI allows users to easily select components, program placement movements, input component and inspection data, and control SPC data collection. This significantly reduces setup and development time. VITROX VB50 is designed for high throughput and high production yields. Its advanced technology and automation capabilities make it the ideal platform for PCB assembly and inspection. The equipment is designed for reliability, durability, and versatility, making it a perfect choice for PCB assembly and manufacturing.

There are no reviews yet