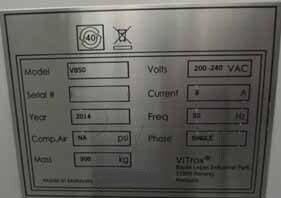

Used VITROX VB50 #9308372 for sale

URL successfully copied!

Tap to zoom

VITROX VB50 is a PC board assembly and manufacturing equipment that is designed to provide end-users with comprehensive control over the entire production process. This system is ideal for users in need of high-precision and rapid component placement on both single- and double-sided PCBs. VITROX VB 50 provides a variety of features that enable users to ensure efficient and precise component handling, including: a high-resolution vision unit which aligns components, a dual-head Panasonic chip shooter, a vacuum flux coating machine, a precision placement head, an air nozzles for cleaning, and an automated optical inspection (AOI) module. VB50's vision tool can be used to precisely align and locate components utilizing the asset's 2xM zoom lens. This lens can be used to accurately calculate component height and rotation measurements, as well as helping to verify the accuracy of the placement location. The dual-head Panasonic chip shooter is equipped with an enhanced placer head, enabling precise placement of components up to 16mm, as well as a ball-screw and servo motion control that ensures accurate and repeatable placement results. VB 50's Vacuum Flux coating model allows for efficient component preheating while also applying a uniform layer of flux on the surface of the component prior to placement. This eliminates the need for manual flux application ensuring accuracy in each cycle. An advanced placement head is also included in the equipment that allows for rapid and accurate component placement with ultrasonic vibration and improved force control. In addition, VITROX VB50 is equipped with a module for automated optical inspection of placed components to ensure accuracy in each step of the production process. This AOI module is integrated into the system and can be accessed from any PC that is connected to the internet. Overall, VITROX VB 50 is a comprehensive unit that allows users to get complete control over their entire production process. This machine provides high sensitivity, as well as outstanding throughput rates and overall flexibility, to ensure efficient and reliable component placement.

There are no reviews yet