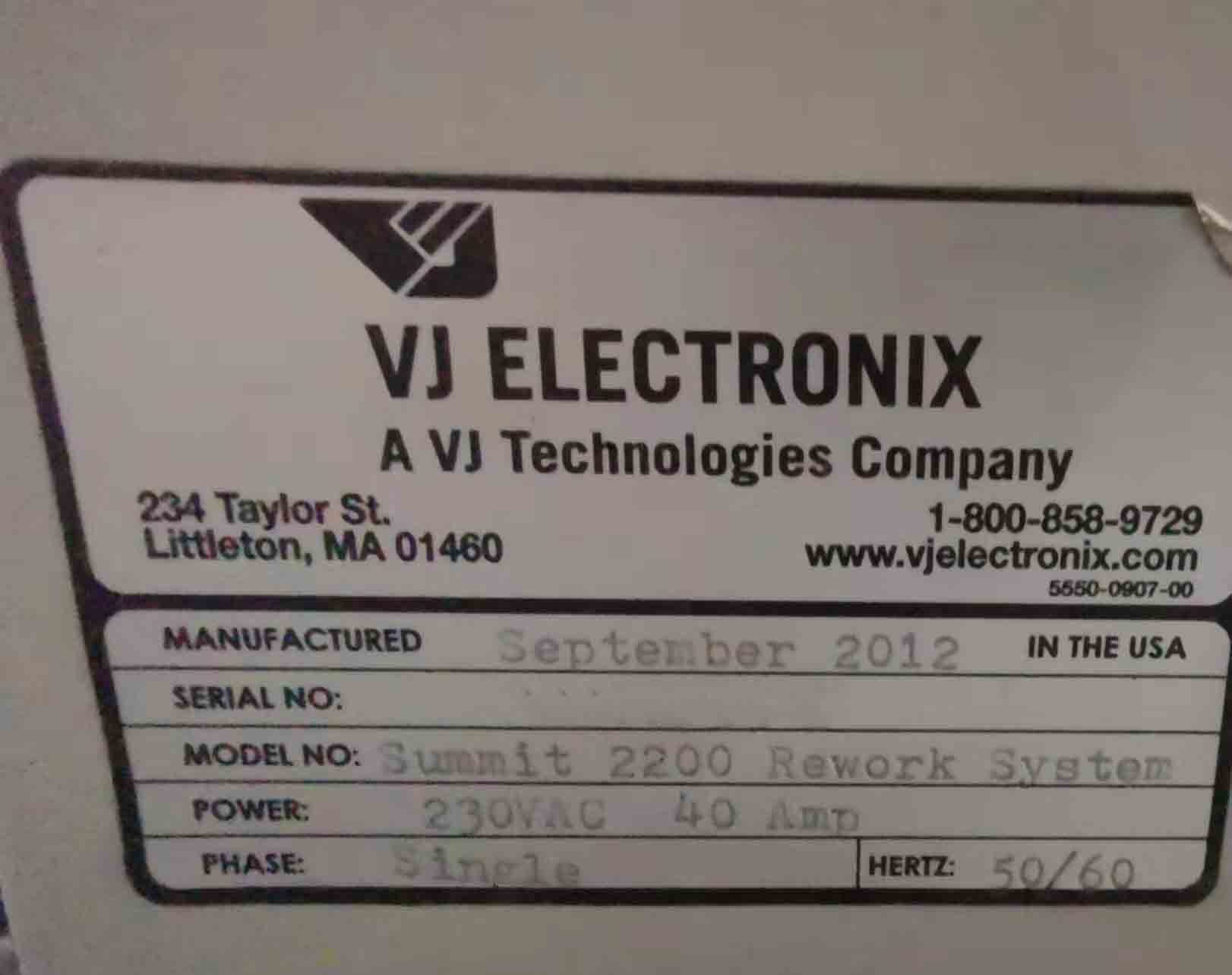

Used VJ ELECTRONIX Summit 2200 #9411239 for sale

URL successfully copied!

Tap to zoom

VJ ELECTRONIX Summit 2200 is an automated pcb assembly and manufacturing equipment that allows for high-volume production of even the most complex board designs. Summit 2200 utilizes its four-quadrant vision system to identify placement components and to ensure their accuracy. Additionally, the machine can print solder paste and place components to a printed circuit board. Utilizing its pioneering vision camera unit, VJ ELECTRONIX Summit 2200 has the capability to inspect components during the assembly process. The machine is capable of handling components up to 80mm in width and 130mm in length. Summit 2200 can be integrated with other SMT machines, helping optimize the assembly process and increase manufacturing efficiencies. Advanced feeder stations are available, each with their own independent vision machine that can identify what parts are currently in the assembly process. The machine also features an adjustable dual-lane tool to achieve greater throughput. VJ ELECTRONIX Summit 2200's 4-axis robotic arm helps with placement and accuracy of the parts, ultimately increasing production quality. It is capable of placing components in various angles and locations. Furthermore, the robotic arm is able to place parts with 0.005mm accuracy. Summit 2200 also offers a full range of successful placement on leaded and leadless components, helping to ensure quality assembly. The machines can place 25,000 parts per hour and are capable of batch placement of components with 0.03mm accuracy. VJ ELECTRONIX Summit 2200 allows for easy programming via its user-friendly GUI, and offers time-saving features such as its autoAdjustSMRT and autoAlignSMRT software which automatically adjust and align components from various sources. The machine also includes an advanced traceability asset to track components placed by the machine. Summit 2200 is a sophisticated pc board assembly and manufacturing model that allows for high-volume production of even the most complex board designs. Its features and technologies allow for efficient, accurate, and reliable placement of components and ultimately helps to increase production quality and overall efficiency.

There are no reviews yet