Used YAMAHA i-Cube II #9059627 for sale

URL successfully copied!

Tap to zoom

ID: 9059627

Vintage: 2005

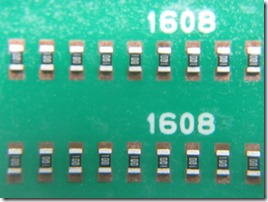

Hybrid placer

Model #: YHP-2

Flow direction: Right to left (front rail fixed)

4M type

PCB: Max: 300 mm (L) x 200 mm (W); Min: 50 mm (L) x 30 mm (W)

Carriable feeder quantity: Max (28) pcs.

Auto nozzle changer

3D Mounting function

High resolution digital camera for I-Cube II

Recognition for all ball of flip chip

Multi recognition camera (20 mm Field of view)

Parts: 0.3 ~ 15 mm

Includes: ~(13) CL Feeders

Running hours: 842h

Warehoused

2005 vintage.

YAMAHA i-Cube II is a fully automated pc board assembly and manufacturing equipment that combines the advantages of conventional line array technology and high-mix low-volume production capability. YAMAHA I-CUBEII is capable of fulfilling both full-volume and variant-production demands. Its versatile functions can meet different customer requirements in multiple industries. I-CUBE-II system utilizes advanced high-performance machinery and peripherals. It incorporates a conveyor unit for loading and unloading the boards, PC board loading and unloading jigs, and a robot for handling components ranging from fine-pitch to large-scale. The machine further has the ability to store multiple stocks of components which can be supplemented via automatic component feeding. YAMAHA I-CUBE-II is equipped with an intelligent platform incorporating graphically programmed software, enabling a quick and hassle-free changeover from one job to another. This highly efficient production control feature speeds up tool set-up and minimizes downtime. Additionally, a safety implementation asset is in library for all production activities. Furthermore, the model is constructed to fit a limited space; thereby conserving energy while saving room. Furthermore, i-Cube II equipment is designed with flexible manufacturing and quality assurance capabilities. It is capable of machining and assembling components of various sizes, and tracks the data of the motherboard parts for quality assurance. In addition, this system can be integrated with the optional Total Quality Assurance Unit, which uses machine vision to scan parameters and ensure quality assurance accuracy throughout the production process. Finally, the machine has the capability to provide realtime feedback to the user and various factory automation systems. This feature enables total control over all manufacturing processes and allows for quick troubleshooting in case of errors. In summary, I-CUBEII is a comprehensive, cost-effective, and efficient pc board assembly and manufacturing tool. Its flexibility, high-performance features, and intelligent platform provide users with a competitive advantage in the global market.

There are no reviews yet