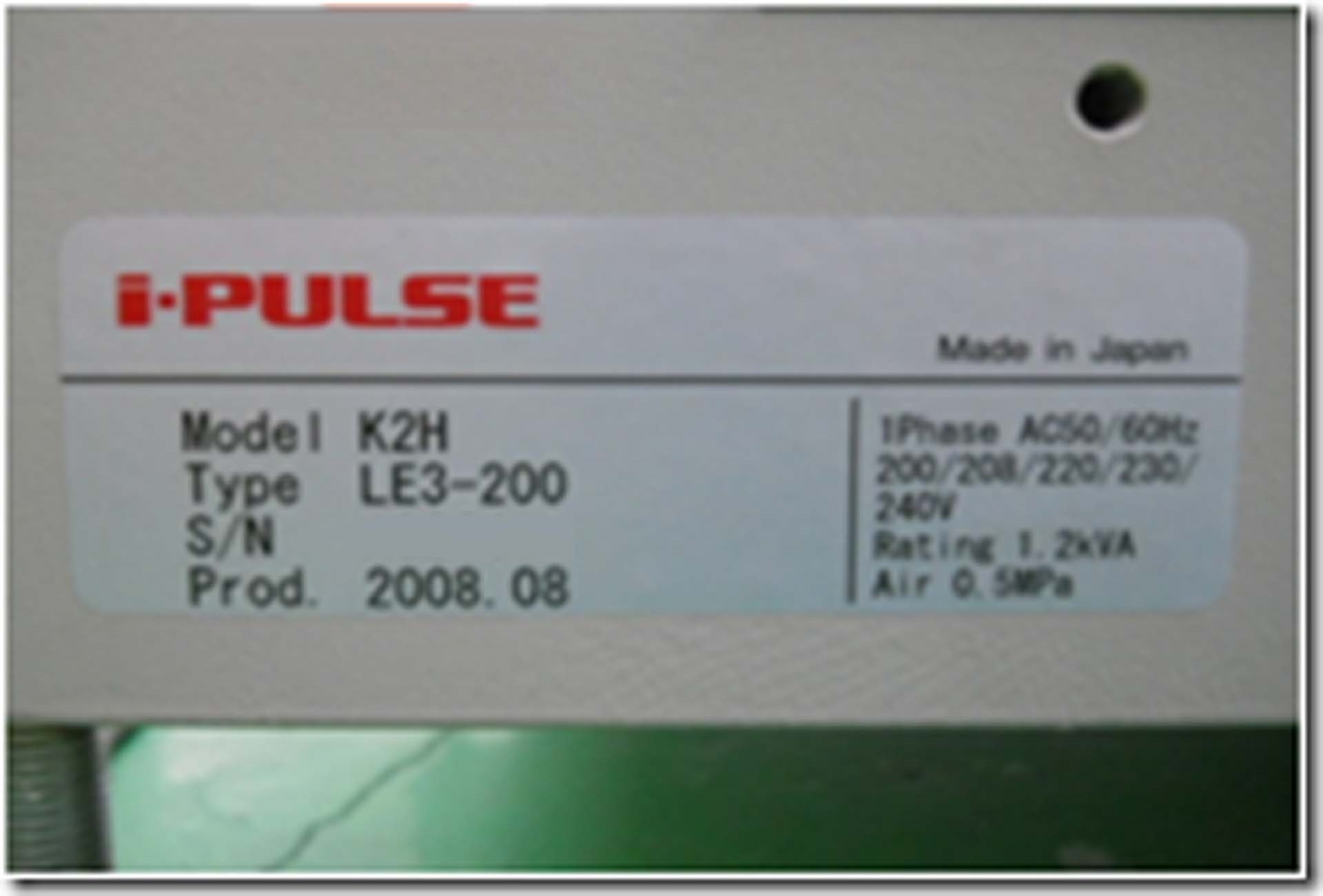

Used YAMAHA / I-PULSE K2H #9121558 for sale

URL successfully copied!

Tap to zoom

ID: 9121558

Vintage: 2008

Inline SPI / AOI system

Flow: Right to left

Front fixed

PCB: 50 x 50 mm to 250 x 330 mm

Tact: 0.19 sec

Resolution: 19 u

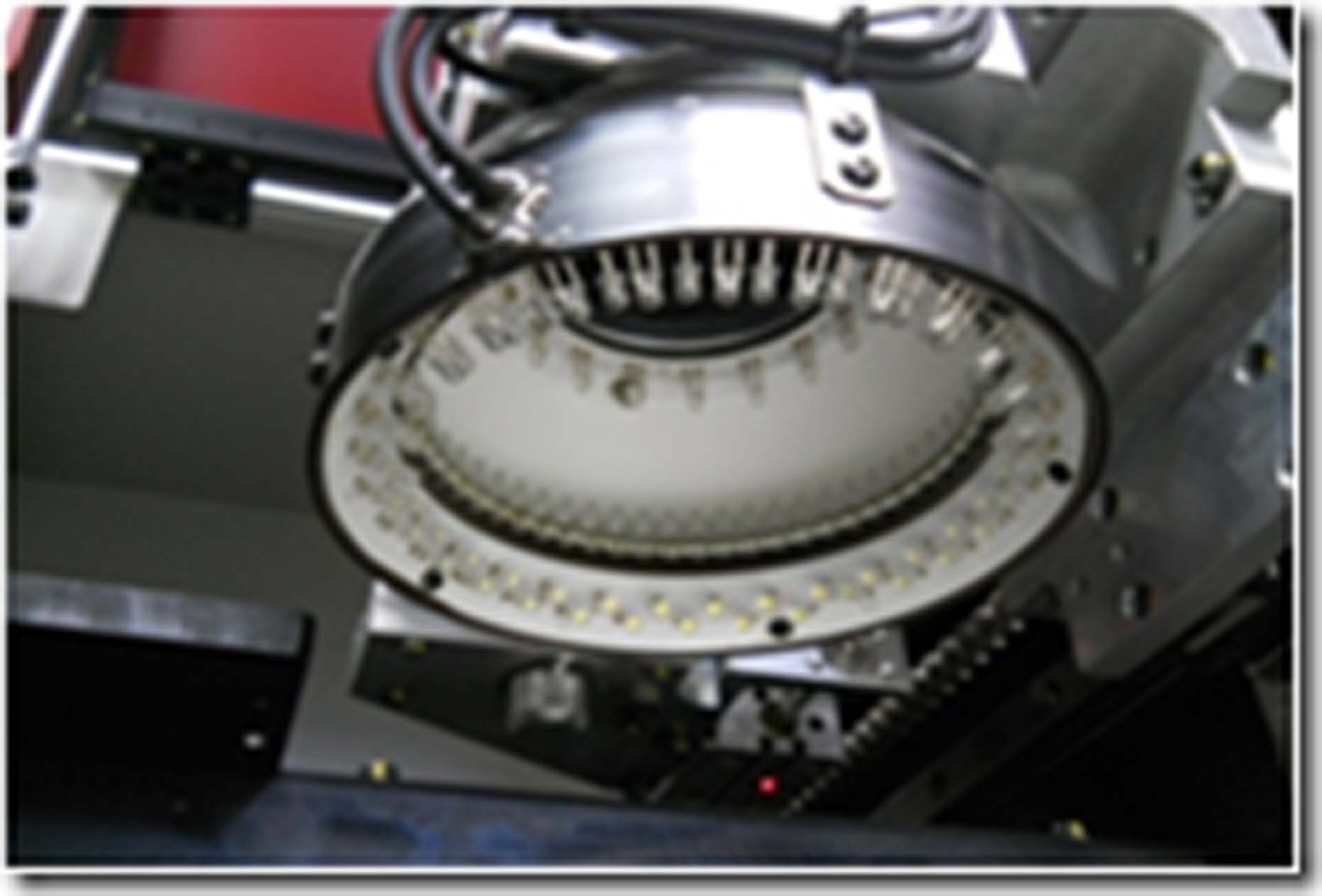

CCD Camera + white LED

PCB Thickness: 0.3-3.2 mm

3 Steps LED dome ilumination:

Upper / Red

Middle / White

Lower white

Maximum parts height:

Upper: 28 mm

Lower: 25 mm

2008 vintage.

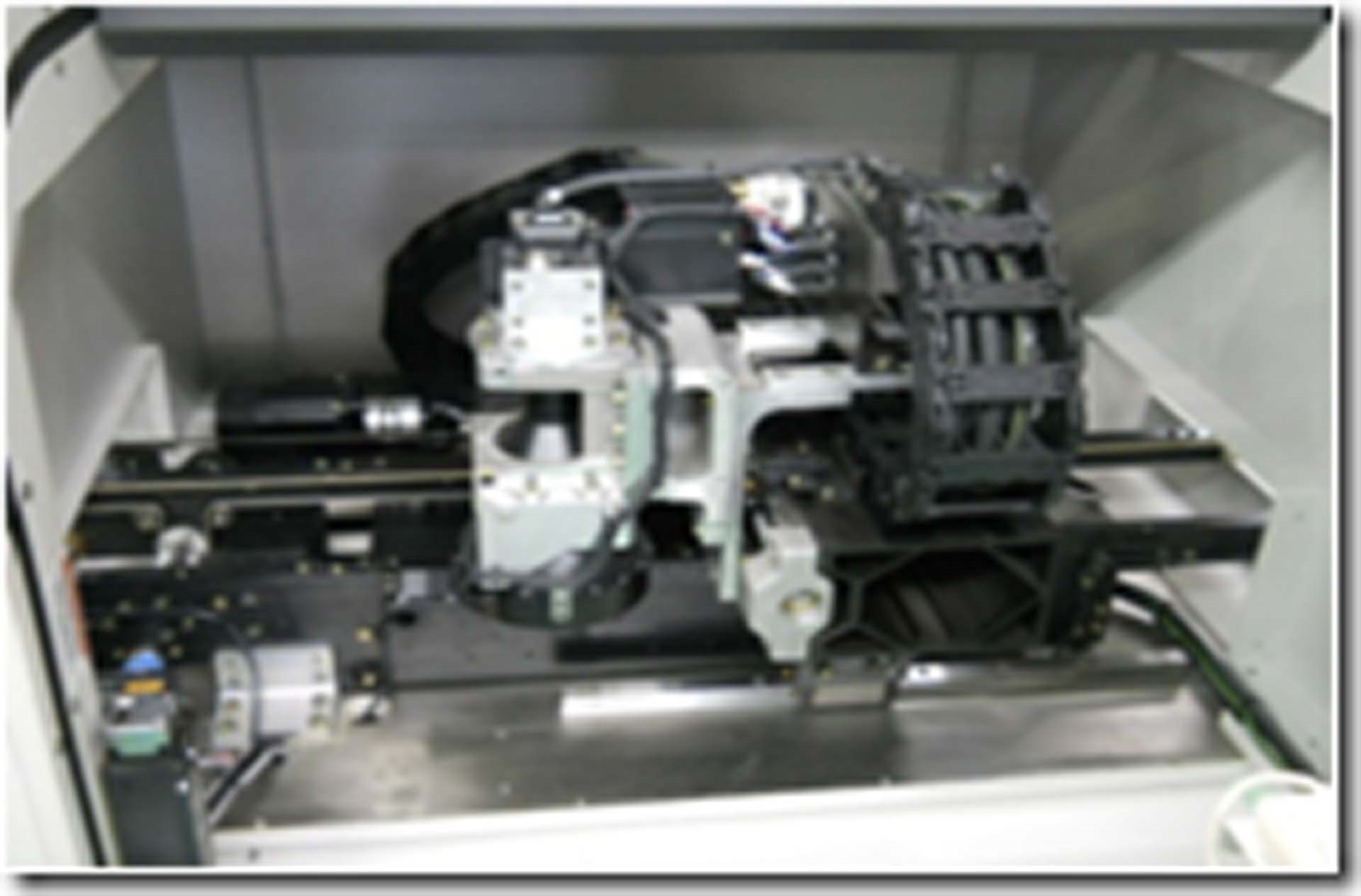

YAMAHA / I-PULSE K2H is an automated pick-and-place machine designed for high-precision, high-speed assembly of customised printed circuit boards. YAMAHA K2H offers advanced automation, with vision and measuring systems for accurate identification, placement, and registration of components, as well as final product inspection capabilities. It handles a variety of components, from 0.4mm to 60 mm long and 0.4mm to 25 mm thick. I-PULSE K2H is powered by a brushless direct-drive motor, and is capable of handling up to 20000 components per hour with a 12-spindle head for high stack operation. The equipment also features powerful, intuitive software with programming capabilities for rapid custom setup. K2H is fully automated, from component recognition to placement and firing. A built in "smart vision" system recognizes components and provides orientation to the placement head. Four vision cameras simultaneously verify the placement accuracy of components with straight, angled, and bottom mount options. YAMAHA / I-PULSE K2H also boasts a unique 3-Axis Force Monitors which constantly monitor and adjust nozzle force and pressure applied to components. This allows for the correct and consistent delivery of components to the board, ensuring accurate placement. In addition, YAMAHA proprietary Anti-Static Air Flow Unit further increases placement accuracy. The machine reduces static electricity, allows the component to adhere to the board, and increases transport efficiency - all of which help prevent component movement, rejects, and product damage. YAMAHA K2H also features a patented custom nozzle field that is designed to match the shape and size of the component for optimal placement. The tool also utilizes a patented force sensing technology which gauges the exact force applied to the board. A data recorder also allows the asset to store all pertinent information needed for traceability and quality assurance. This record also ensures parts can be identified and isolated in case of defective product and prematurely fired boards. I-PULSE K2H comes complete with a robotic arm and start-up kit so that the model is ready to produce your boards right out of the box. From servicing to support, I-PULSE is committed to providing their customers with the best experience possible.

There are no reviews yet