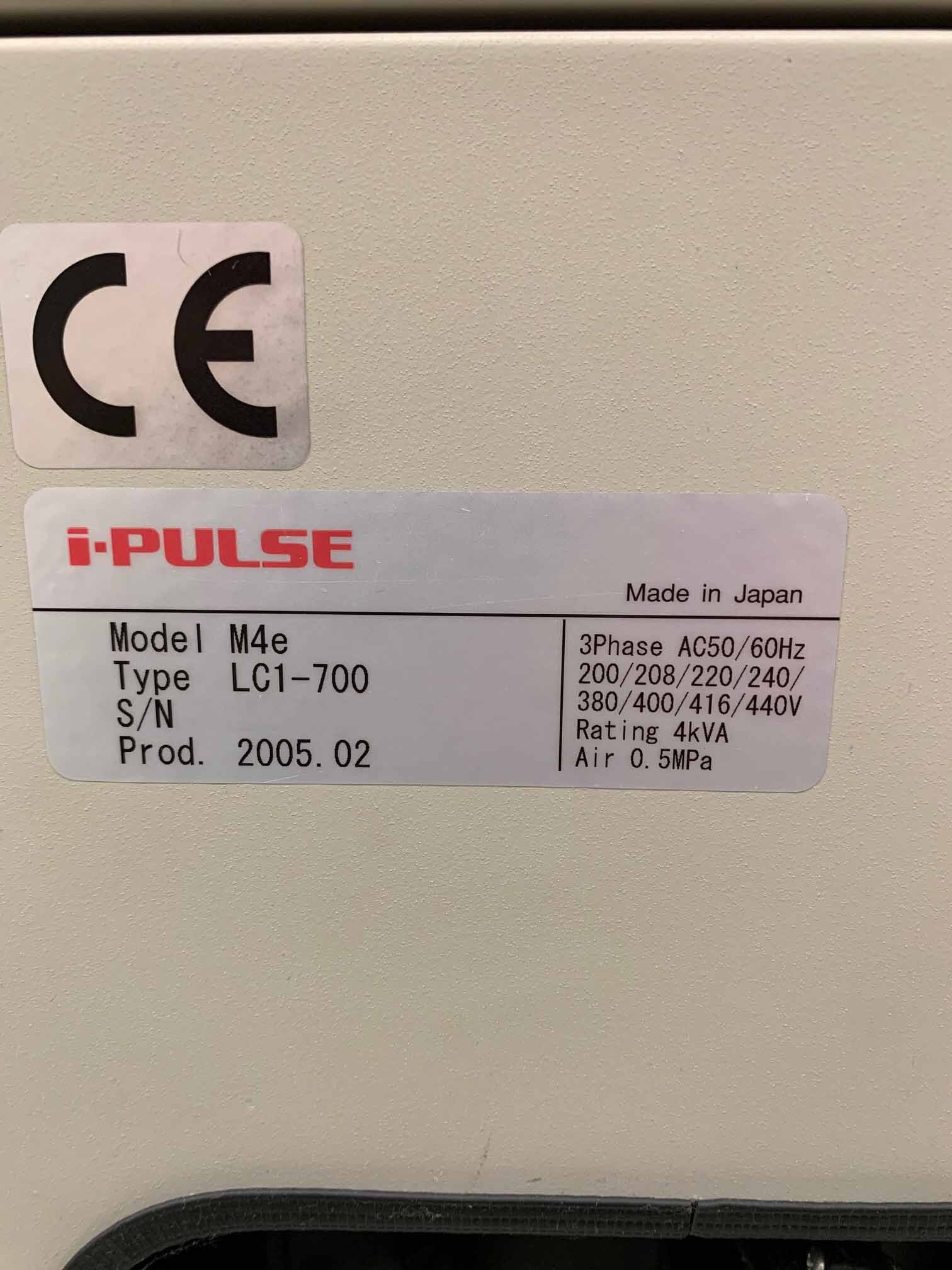

Used YAMAHA i Pulse M4E #9375734 for sale

URL successfully copied!

Tap to zoom

ID: 9375734

Vintage: 2005

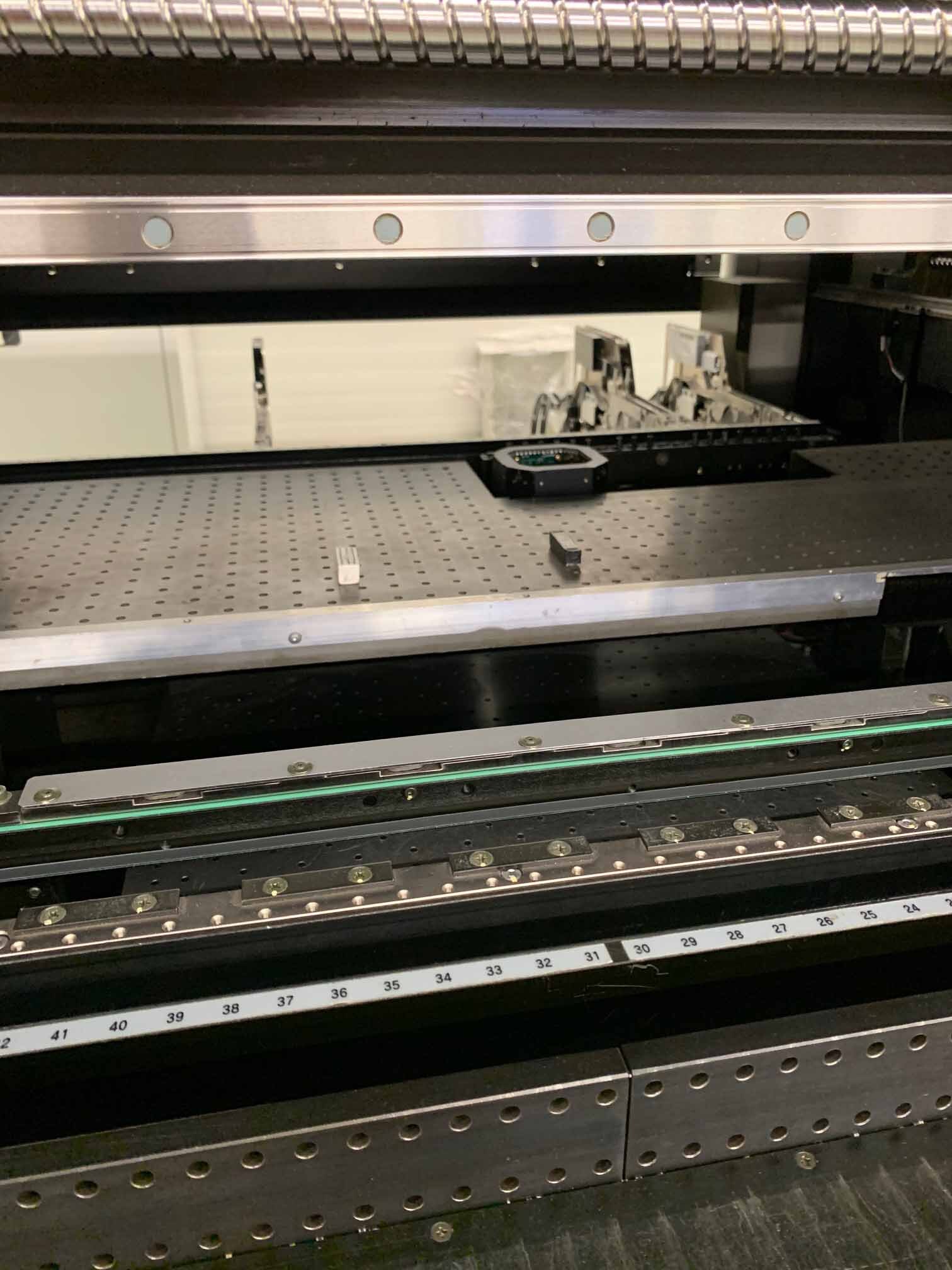

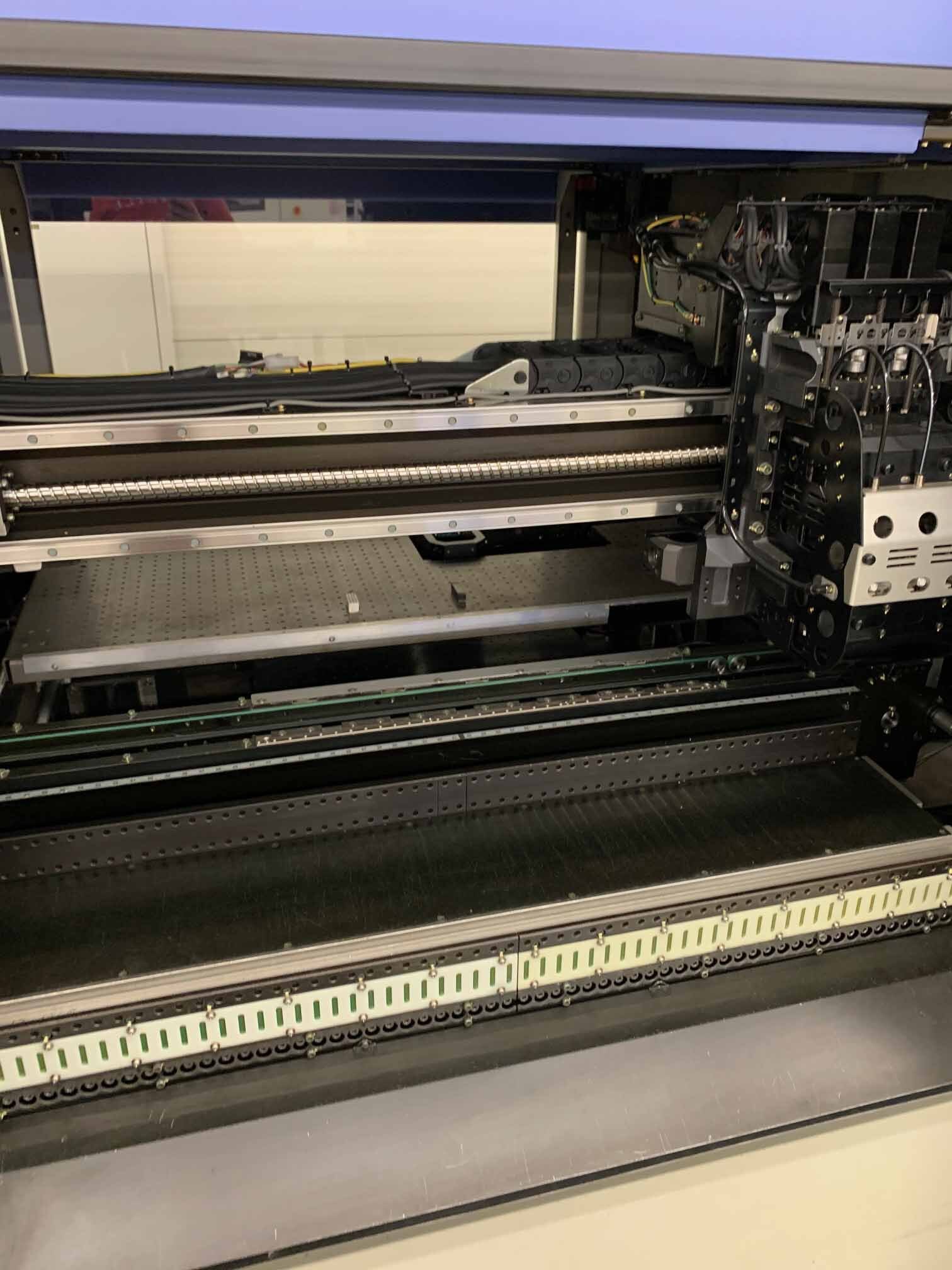

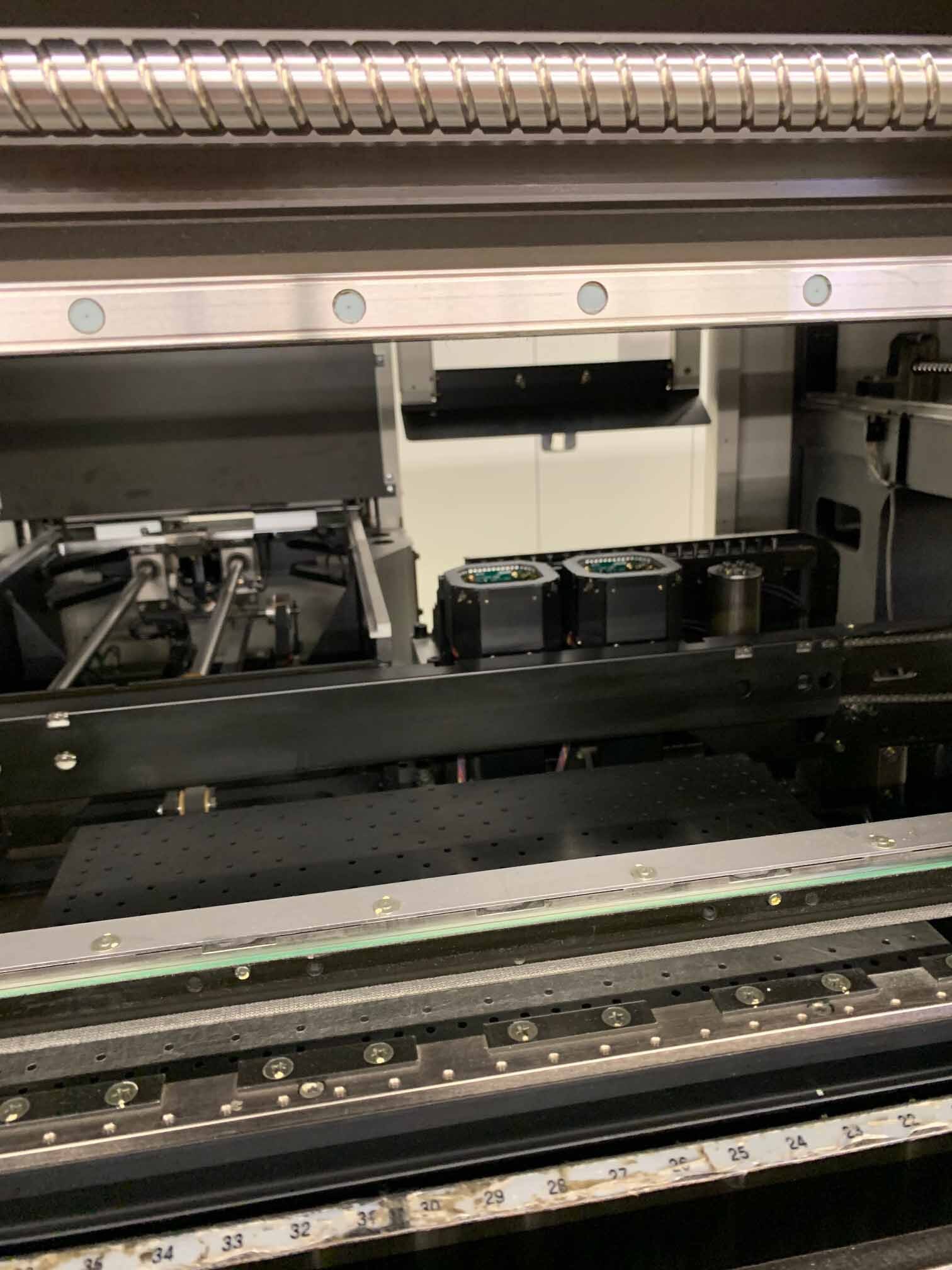

Chip mounter

FC05 Camera

CCA (90) Feeders

Vibratory feeder

2005 vintage.

YAMAHA i Pulse M4E is a complete production line equipment for advanced PC board assembly and manufacturing processes. This innovative system incorporates features such as three-dimensional inspection technology, digital image processing and automated opto-electrical alignments. The unit optimizes efficiency and accuracy in the overall manufacturing process, delivering superior performance that greatly increases production output. YAMAHA M4E features a high-speed vision camera that will capture analysis results and projections. This high-performance machine is capable of inspecting up to 4,096 individual components at once. The real-time processing speed and accuracy of the cameras enhances feedback and analysis results. The tool also includes speed upgrades, a 4-axis transportation platform for fine pitch and chip components, and an automated opto-electrical alignment asset. The onboard software includes a streamlined material traceability model that can determine material traceability down to component-level board assembly and manufacturing. Through this equipment, manufacturers can easily identify problems, track individual component progress and optimize the manufacturing cycle. The software also provides comprehensive production reports for high-level quality assurance. Additionally, YAMAHA offers a wide range of value-added options including a network of upstream inspection systems, an offline service for loading and unloading boards, and batch loading for higher-volume production runs. This network of integrated production systems reduces costs and saves time, giving manufacturers the capability to maximize production resources. All in all, i Pulse M4E is an incredibly powerful and reliable PC board assembly and manufacturing system. Its integrated three-dimensional inspection, digital image processing and automated opto-electrical alignment systems combine to create a streamlined unit that maximizes efficiency and accuracy. In addition, its onboard software and widespread availability of value-added options make it a cost effective solution for any modern production facility.

There are no reviews yet