Used YAMAHA V-100 XGP #9035876 for sale

URL successfully copied!

Tap to zoom

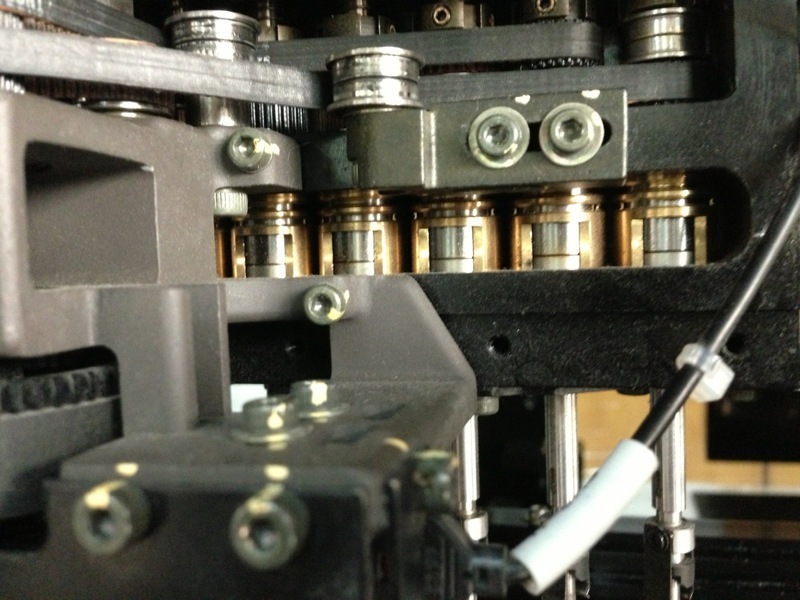

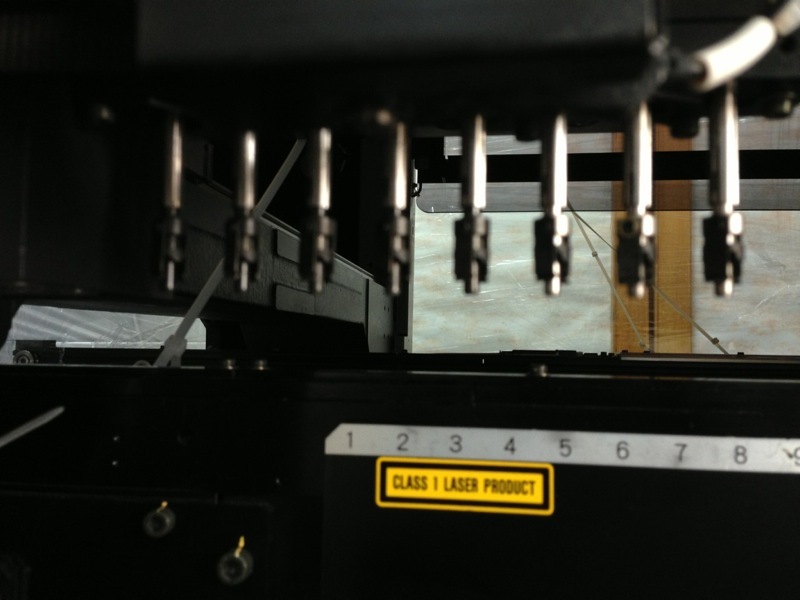

YAMAHA V-100 XGP is a high-performance professional production line for small parts assembly and board manufacturing. Developed and manufactured by YAMAHA, V-100 XGP is designed to reduce the time and labor required in board manufacturing processes, providing precise and fast results. The XGP equipment consists of a highly sophisticated system of automated components. YAMAHA 'Uni-Form Design' positions the x-axis track and linear body in a straight line, making the unit strong and efficient. For effective component placement, YAMAHA V-100 XGP features a particle-measuring head which scans the surface of the board using a pin array. The pin array detects the position of the components' leads and the x-axis accurately moves the head to the desired location for accurate placement. The head can also detect component alignment and directly center components before attaching them to the board. The V-100 also features a sliding print head which ensures precise or complex component movements. It uses an adjustable arm to move components without manual intervention, which reduces production time and labor. The XY-axis machine also covers a wide range of movement and is designed with a minimum height of 60 mm, giving higher component placement capacity. The rotating capability provides a 360-degree range of movement, allowing you to place parts accurately and quickly. V-100 XGP board mounting tool is designed with a minimum component distortion of 0.01mm, making it suitable for a variety of board sizes. The asset is also capable of processing components of varying sizes and provides quick and accurate placement of components with a maximum accuracy of 0.08mm. YAMAHA also provides an automatic nozzle exchange model, enabling multiple nozzle types to be installed and the automated selection of the nozzle size for different component sizes. Overall, YAMAHA V-100 XGP board mounting equipment is a highly advanced automated production line for small parts assembly and board manufacturing. It uses sophisticated sensing and positioning systems, ensuring accuracy, high speed production, and quick component placement. The system is also versatile, accommodating components of varying sizes while providing a simple operation process.

There are no reviews yet