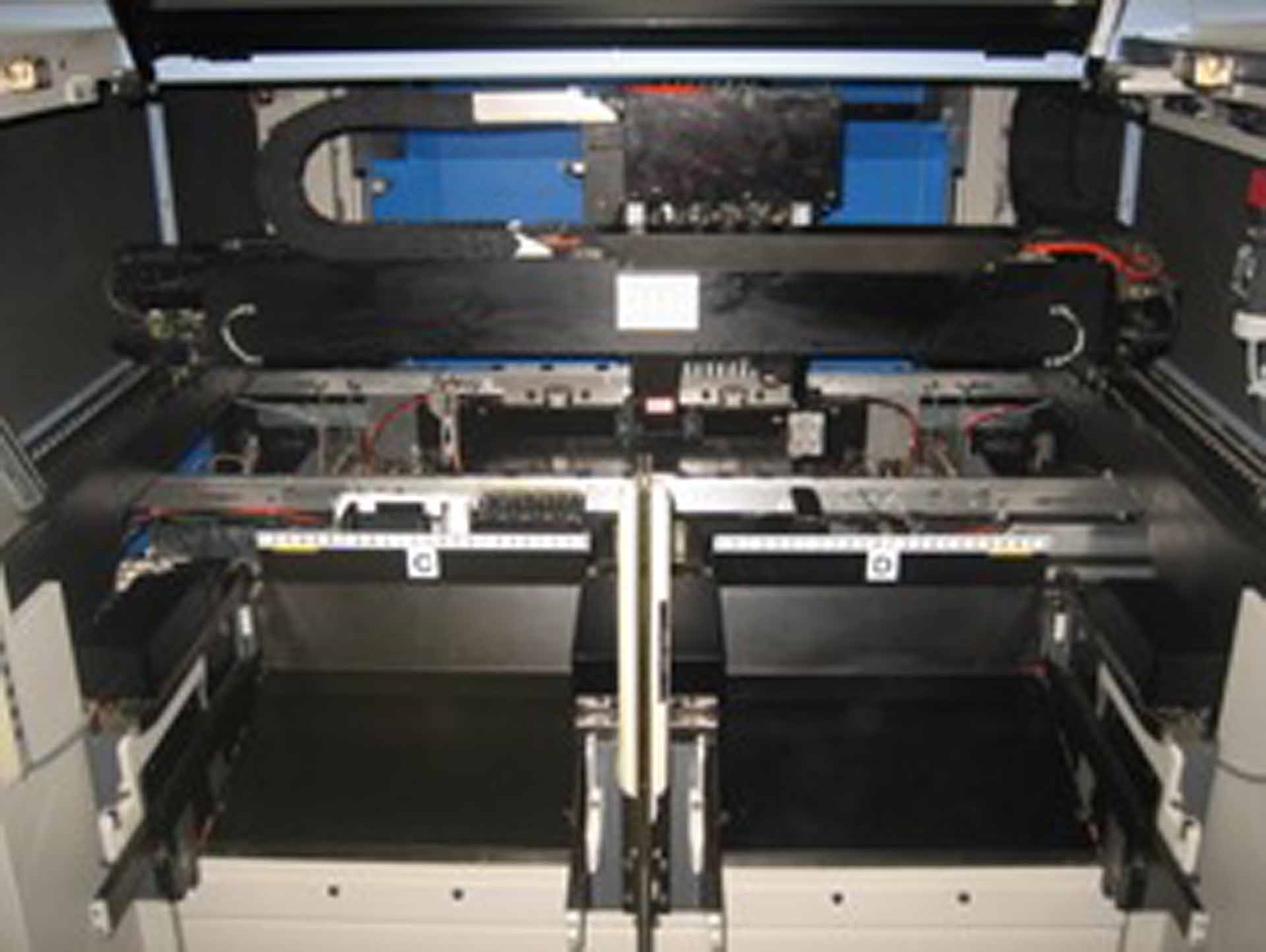

Used YAMAHA YG-100B #9247545 for sale

URL successfully copied!

Tap to zoom

ID: 9247545

Vintage: 2006

Chip mounter

Running hours: Above 16,803

Flow direction: Right to left (Front fixed)

(8) Inline multiheads: SF type

PCB Maximum: 510L x 440W mm

(24) Inline feeder changing cart type

Front multi camera: 31 Type (0402~31)

Rear multi camera: 45 Type (0603~45)

Side view camera

Feeder float detection function

Auto nozzle station

Multi tray D-YTF

(27) Feeders

(4) Feeder changing carts

2006 vintage.

YAMAHA YG-100B is a compact, high-performance, PC board assembly and manufacturing equipment for pick and place and soldering applications. Designed with high-speed and precision in mind, YAMAHA YG-100 B offers remarkable flexibility in its operation that is both efficient and economical. Focus is on the speed of operation with YG-100B, as it has a top speed of up to 1000 parts/minute, enabling it to keep up with increased productivity demands. The machine also boasts high accuracy with a repeatability accuracy of +/- 0.01mm and a minimum pitch of 0.25mm. Its dual heads also enable it to complete parallel processing, which allows for improved production times and increased throughput. The versatility of YG-100 B is something to consider when looking for a comprehensive PC board assembly and manufacturing system. It is able to accept multiple types of components and is capable of component attaching, solder paste screening, reflow soldering, and nozzle cleaning. Its flexible operation also allows for the use of standard, heavy-duty, or fine fiducial recognition. The optional DVP (Display Vision Processor) further enhances the flexibility of YAMAHA YG-100B, adding the visual inspection and additional component mounting capabilities to the machine. YAMAHA YG-100 B comes with a wide range of features, one major one being its industry-leading feeder unit. The machine includes up to sixteen universal (8mm) feeders, one non-stop continuous feeder mode, and a metal multi-contact feeder for large components amongst many others. This feeder allows for more efficient operation and is designed with durability in mind for long working life. YG-100B also features an energy-saving design. It is equipped with pneumatically operated components (as opposed to solenoid-operated) to reduce air consumption and noise levels. Additionally, low-temperature air ducts are used to cool the tool, further reducing noise while ensuring optimal temperature control. Overall, YG-100 B is a perfect choice for companies looking for a reliable and cost-effective PC board assembly and manufacturing asset. Its high-speed operation, high accuracy, and versatile features make it an ideal solution for increased production times and decreased turnaround time. Additionally, its energy-saving design ensures efficient operation, lowering costs and long-term energy usage.

There are no reviews yet