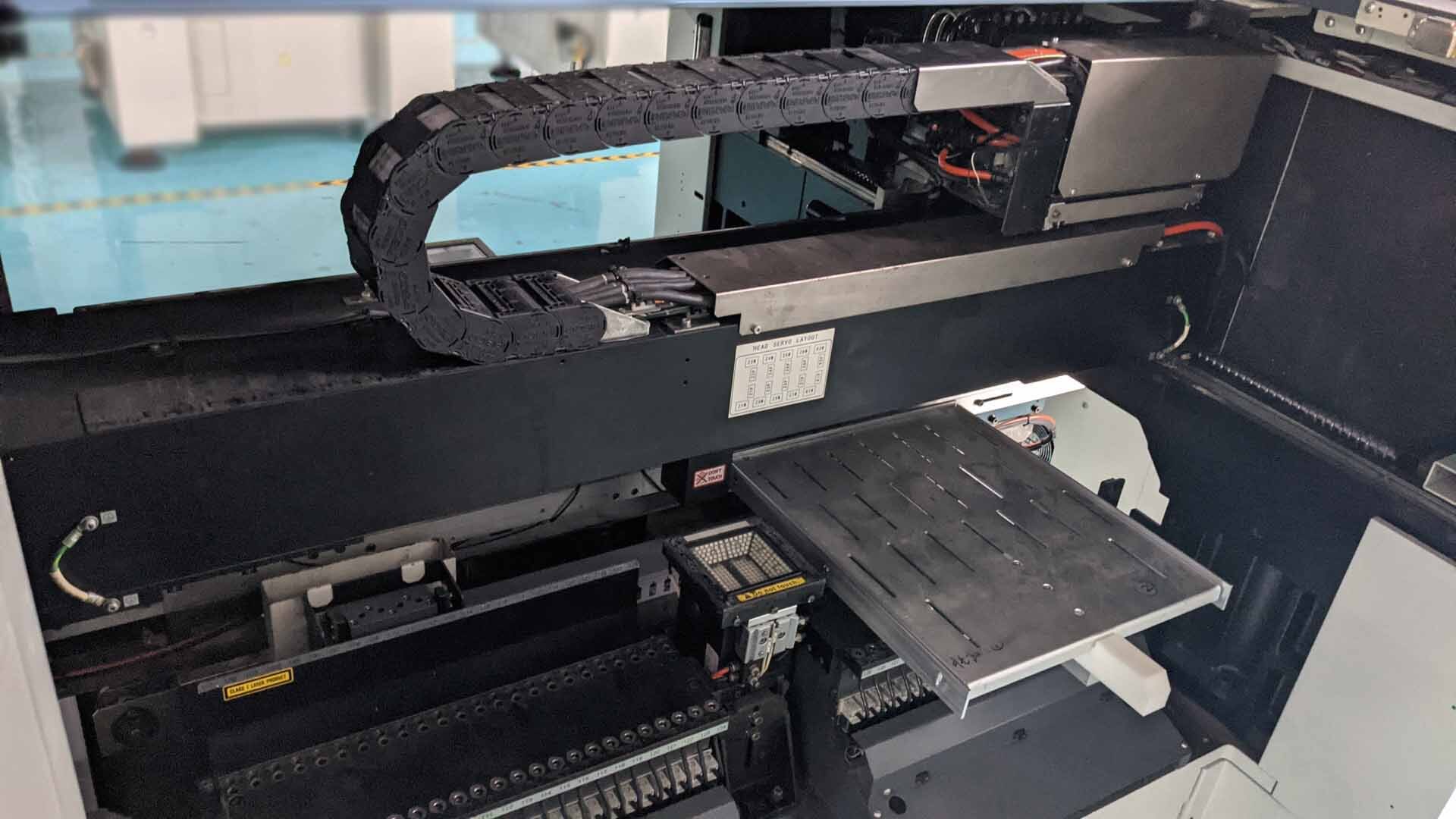

Used YAMAHA YG-100B #9390522 for sale

URL successfully copied!

Tap to zoom

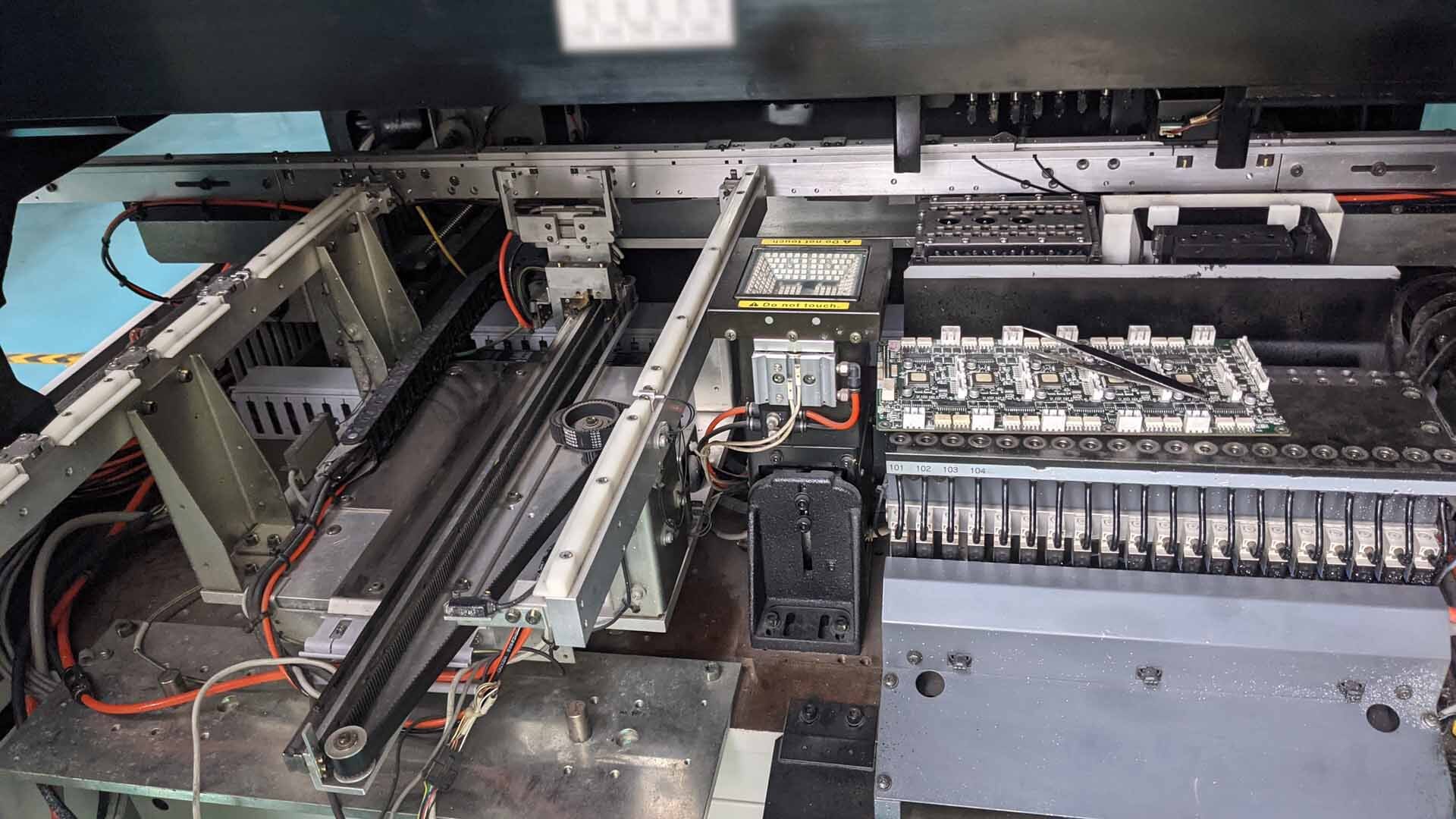

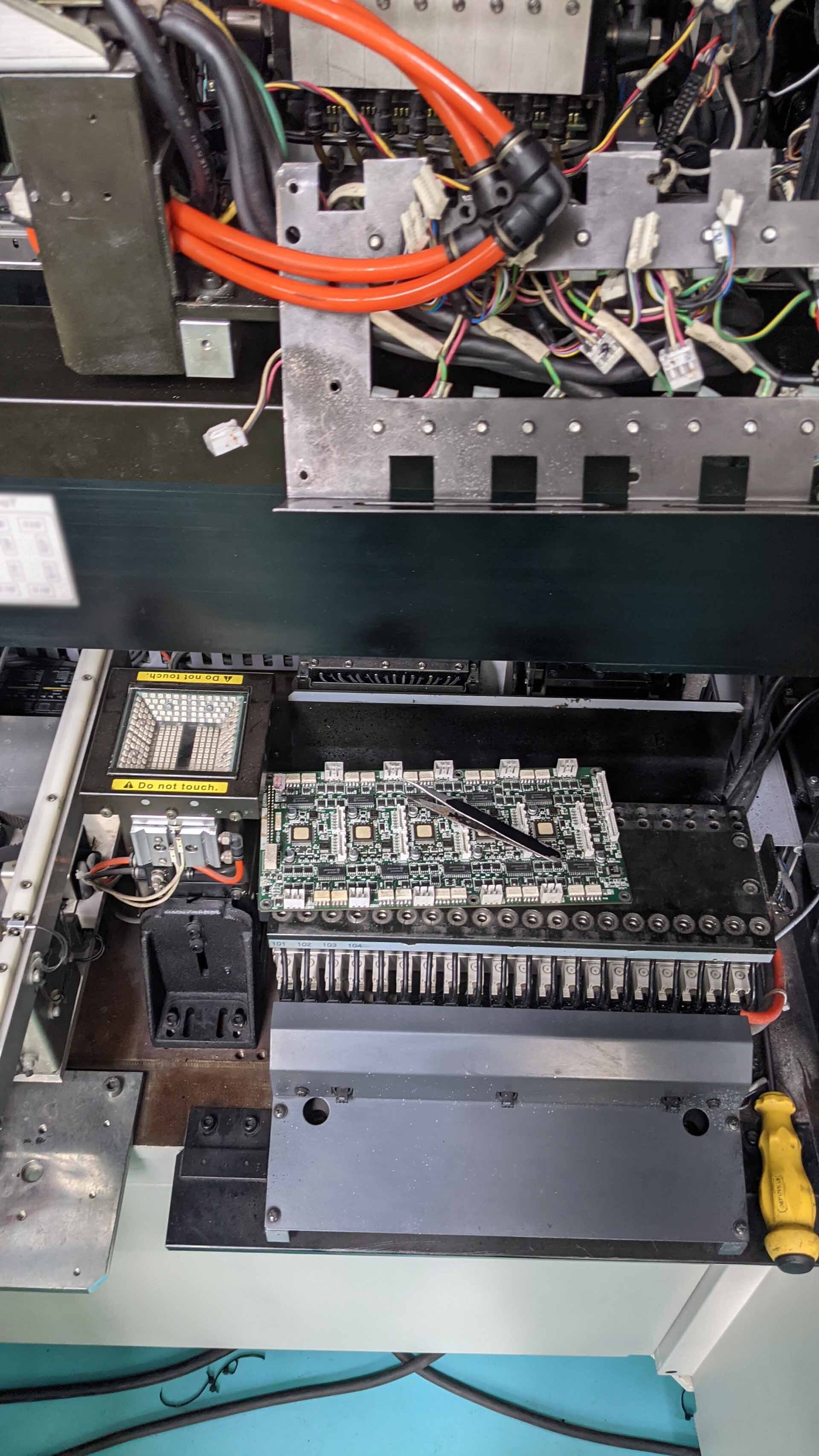

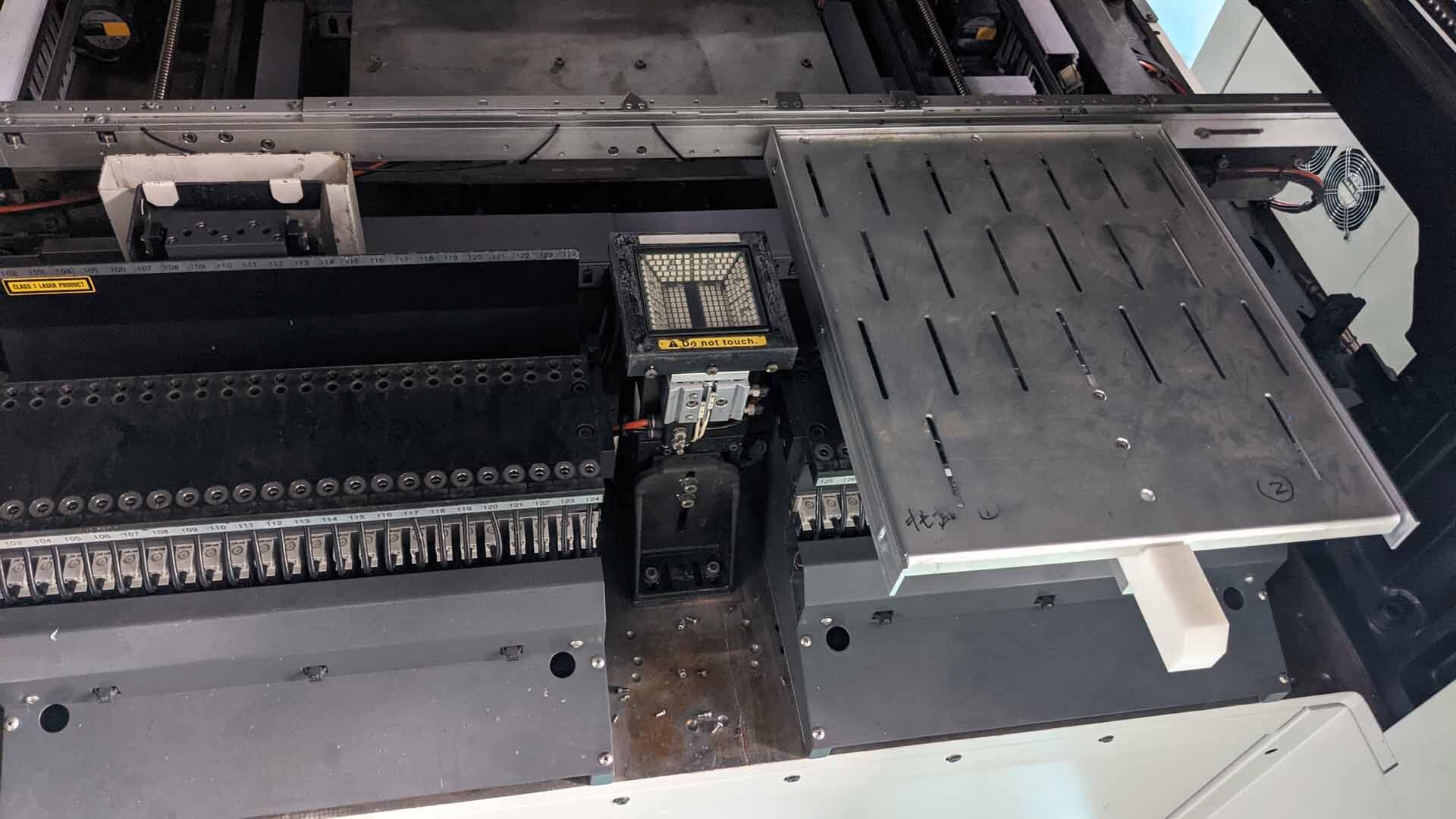

YAMAHA YG-100B PC Board Assembly and Manufacturing Equipment is an automated printing and assembly system that is designed for rapid assembly and production of printed circuit boards (PCBs). It is a multifunctional unit which offers the capability to screen, solder, assembly, and inspect PCBs. The machine comes with a number of advanced features such as programmable motion control, an integrated vacuum tool, vision sensing capabilities, an inverted scan head design, a high speed pick-and-place function, real-time performance monitoring, and automated light indicators. YAMAHA YG-100 B asset is a highly versatile and customizable PC board manufacturing model that has the capability to produce a wide range of PCBs with varying component sizes and configurations. The equipment is able to accommodate single-sided, double-sided, and multi-layer boards, as well as diverse array of component packages such as surface mount technology (SMT), through-hole, and mixed technology. A single destination may be selected for all components, or a separate destination may be dedicated for each component type. The programmable motion control feature of YG-100B enables users to customize the production of PCBs to their own specific needs. By loading component location and size data into the system's memory, users can easily create custom configurations and the unit will then assemble the boards accordingly. The integrated vacuum machine offers a high performance solution for retrieving and placing components, allowing users to increase production speeds and reduce component loss. In addition, an inverted scan head design helps improve the accuracy and reliability of component placement. The tool also features an advanced vision sensing tool which is used to ensure accurate placement of components and inspects board quality and appearance. The high speed pick-and-place feature allows for rapid movement of components from the pick-up point to their respective locations on the board. Real-time process information, such as the number of components placed, production data, and time elapsed, can be monitored and adjusted as needed. Furthermore, the automated light indicators help to alert operators when maintenance is required and when components need to be replaced. Overall, YG-100 B PC Board Assembly and Manufacturing Asset is an ideal solution for creating high quality PCBs. With its advanced features, the model offers unprecedented precision and speed, and is able to easily and quickly adapt to a wide range of production demands. The equipment's intuitive design, comprehensive functionality, and comprehensive maintenance and inspection capabilities make it a great choice for companies looking for efficient and versatile PCB assembly and production systems.

There are no reviews yet