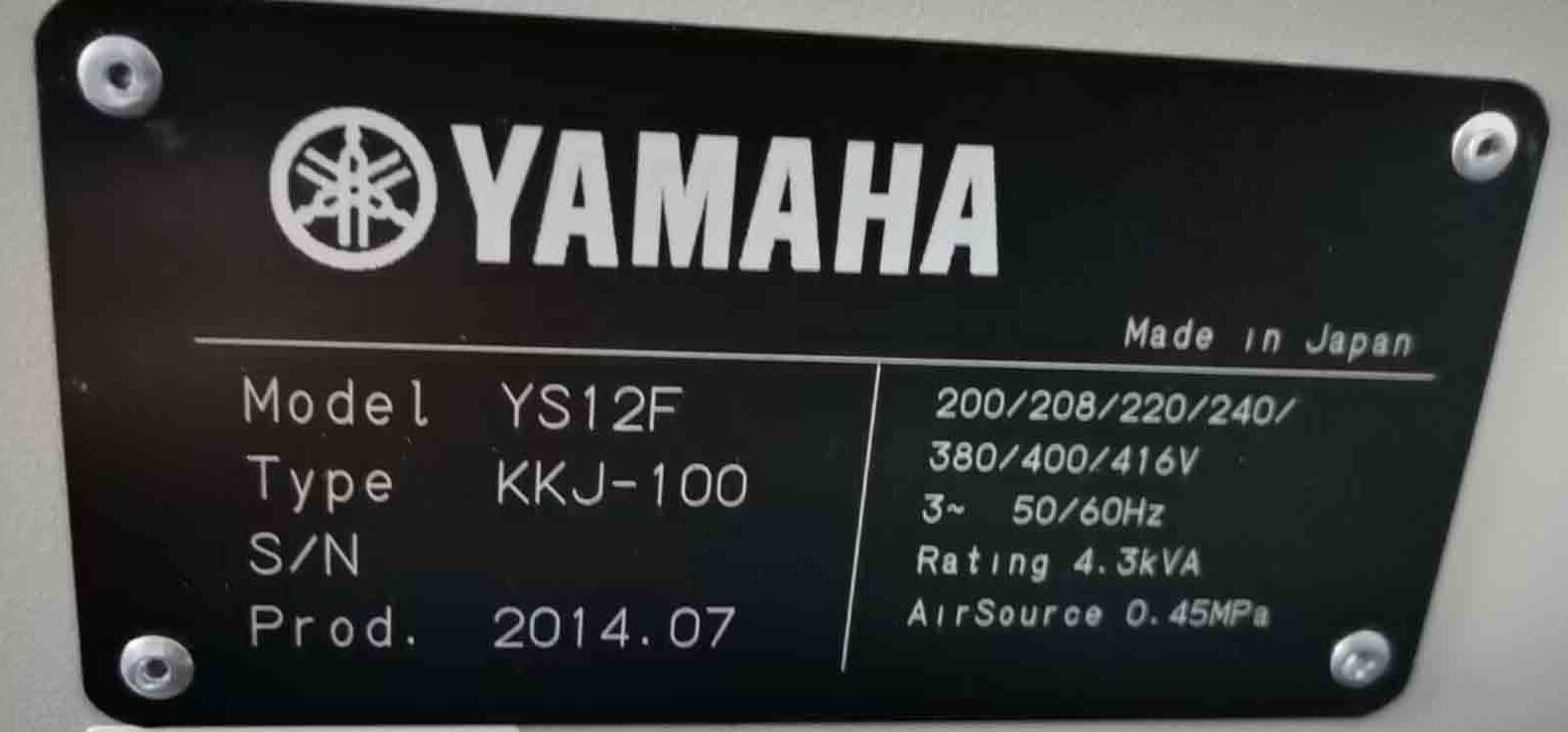

Used YAMAHA YS12F #293592380 for sale

URL successfully copied!

Tap to zoom

YAMAHA YS12F is a highly efficient and versatile PC Board assembly and manufacturing equipment. It is capable of delivering rigid and flexible PC board manufacturing and assembly. The system is equipped with an air bearing XY table, vision and laser-guided pick and place, conformal coating, and reflow soldering. It has a 1.2mm solder-printing thickness and 0.8mm placement capability. YAMAHA YS-12F is capable of placing over 30,000 components per hour on a single board. It also offers advanced assembly kind of capabilities, allowing for front and back-end assembly of each board. The unit is designed to meet the latest objectives of high speed, high quality and high efficiency. It makes the best use of head-on vision combined with a vision-guided pick-and-place tool and a multi-motor robot that can place more components in a single pass. This allows for higher throughput, even for very complex designs. The machine offers a wide range of advanced functions, and is capable of mounting as many as four connectors and wire-harness components onto a single board. It also supports reflow soldering, with its lead-free capability to prevent environmental and health hazards. YS-12 F provides a wide range of visioning options and accessories, including a high-resolution, area-array vision tool, 3D vision, laser-beam length and laser-beam mark detection. These tools improve the accuracy and precision of the assembly process, and enhance quality control. YAMAHA YS-12 F also offers optional parts feeders and auto-loaders that allow for high-speed automated part supply. This minimizes manual handling and operation time, which increases production efficiency. The asset is supported by an intuitive GUI and operation control model, which enables users to quickly and easily program board data and parameters. This reduces production time and increases accuracy, reliability, and productivity. YS-12F is ideal for high volume, precision assembly and manufacturing processes. It is highly flexible, efficient, and cost-effective, and is an excellent choice for those seeking to improve their current PC board production and assembly capabilities.

There are no reviews yet