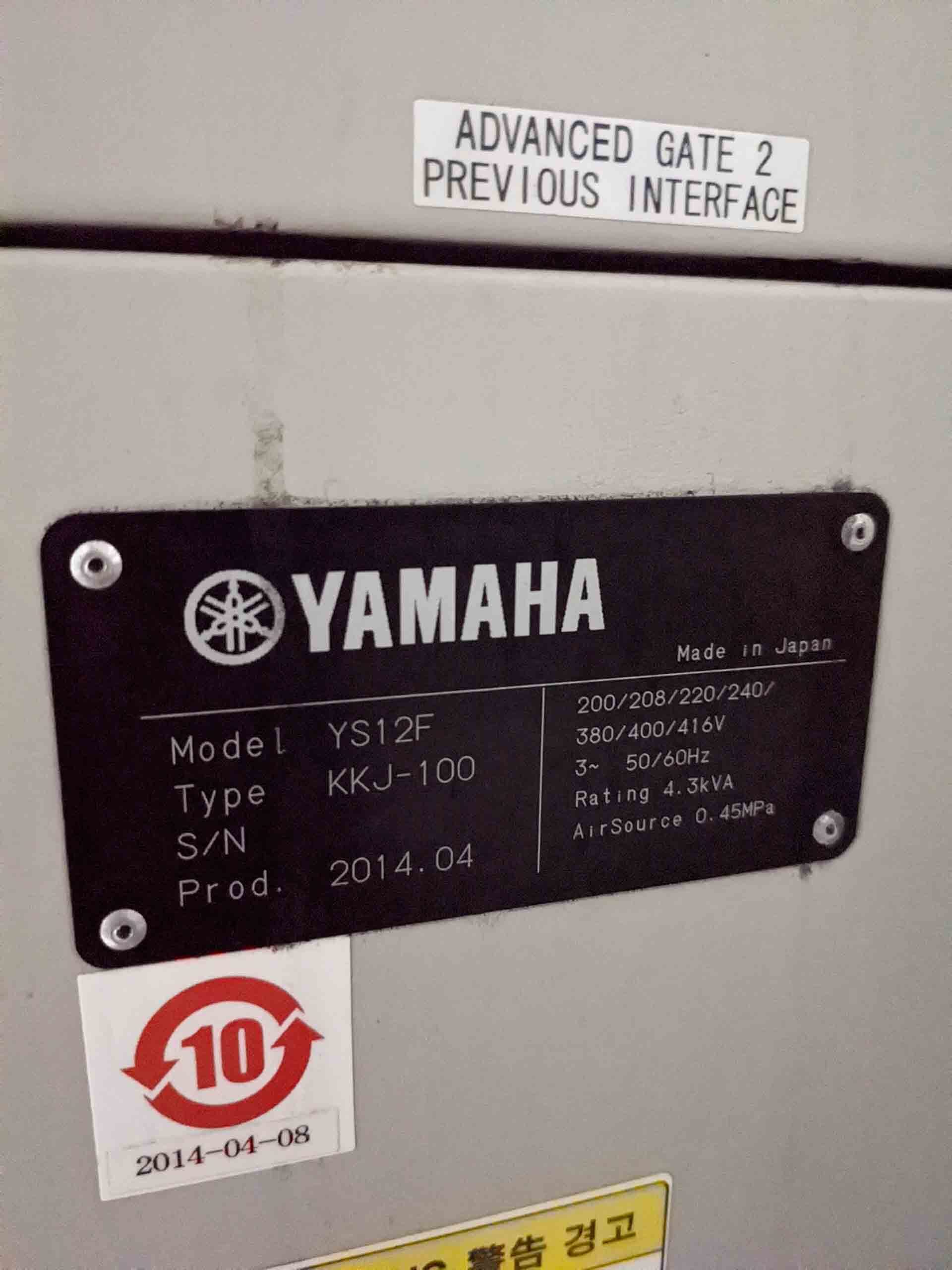

Used YAMAHA YS12F #293605000 for sale

URL successfully copied!

Tap to zoom

YAMAHA YS12F is a highly automated SMT (Surface Mount Technology) assembly line that is widely used for the production of high-volume electronic assemblies. This equipment offers a complete turnkey solution for pc board assembly and manufacturing that includes all the necessary components for a fully automated assembly. YAMAHA YS-12F system is equipped with an intelligent image recognition unit that allows for automatic setup of parts placement, optimal board design, and precise parts placement. It is also equipped with a high-placement accuracy feature that enables it to place the parts with a precision of 0.05 mm. In addition, YS-12 F is designed with a seven-axis robotic arm that allows for movement across three axes when placing and positioning the parts. YS-12F is outfitted with a high-efficiency soldering unit that uses micro-fine tip soldering and prevents unwanted flux build-up. This soldering machine also offers a precise temperature control mechanism that ensures the right temperature is maintained to avoid over-heating. In addition to its complex robotics, YAMAHA YS-12 F is designed with seven degrees of freedom mechanical vision tool. The asset is capable of recognizing and stacking components with a height discrepancy of 0.2mm maximum, thus allowing for precise alignment of parts and precise placement of parts. YS12F also incorporates leading-edge control technology for improved accuracy, reliability, and safety. Component placement and soldering speed can be controlled by electronic or software patterns, as well as a proprietary auto-adjust mechanism that automatically adjusts process parameters according to conditions. YAMAHA YS12F is also incorporated with a maintenance model that allows for easy and convenient service and maintenance. Various tools are available such as parameter software or a laptop communication interface. This equipment also includes a built-in self-diagnosis mode that can detect and detect and solve problems before they occur. YAMAHA YS-12F also has an integrated safety system that prevents incorrect parts placement and over-heating during the manufacturing process. This unit uses an independent environment control board and distortion monitoring unit to provide safe and stable production process. YS-12 F is an extremely efficient and reliable machine and is an ideal choice for high-volume production. Its sophisticated design and cutting-edge technology ensure that the pc boards manufactured through this tool will exceed the most demanding industry standards.

There are no reviews yet