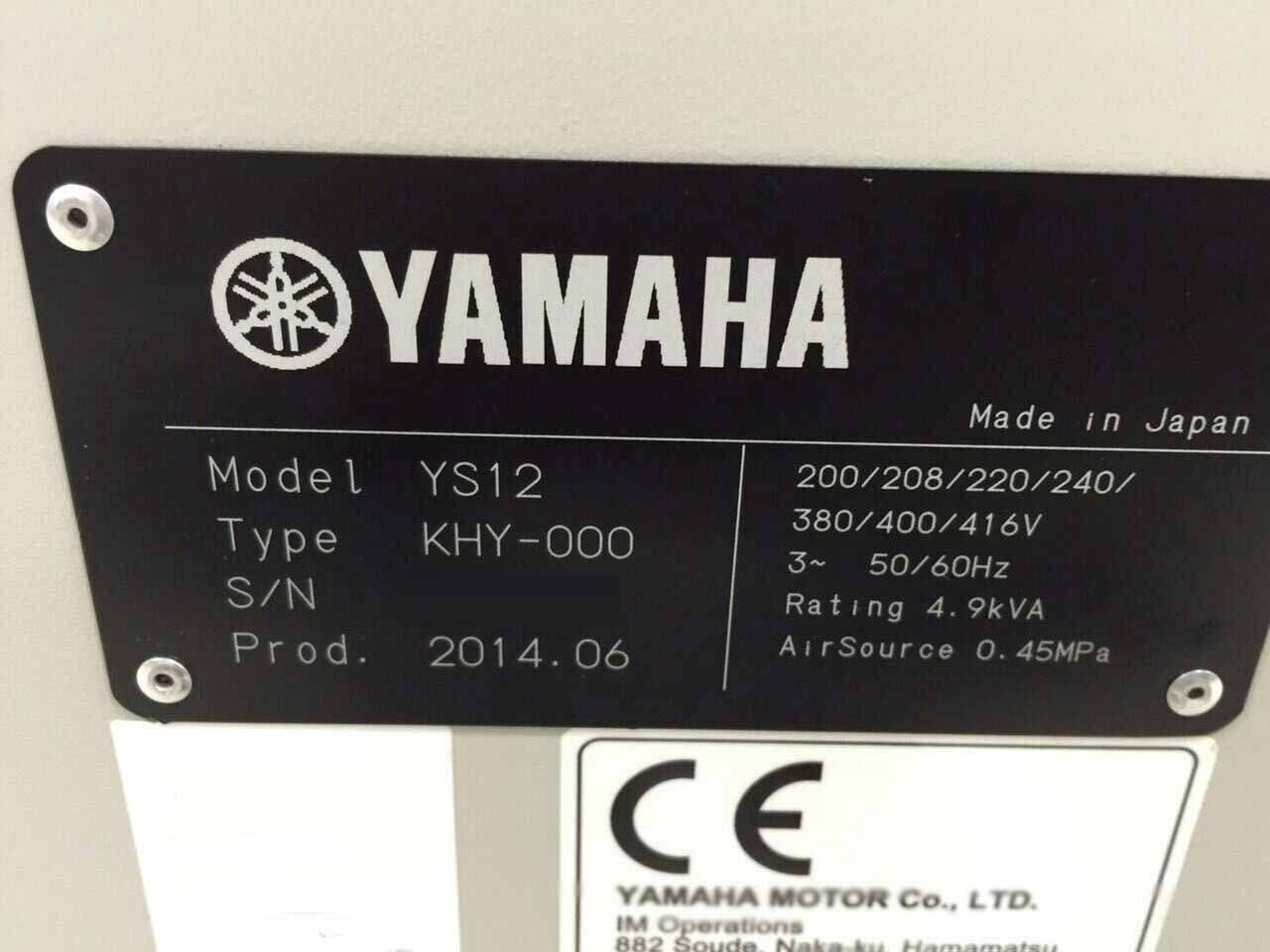

Used YAMAHA YS12F #9153913 for sale

URL successfully copied!

Tap to zoom

ID: 9153913

Vintage: 2014

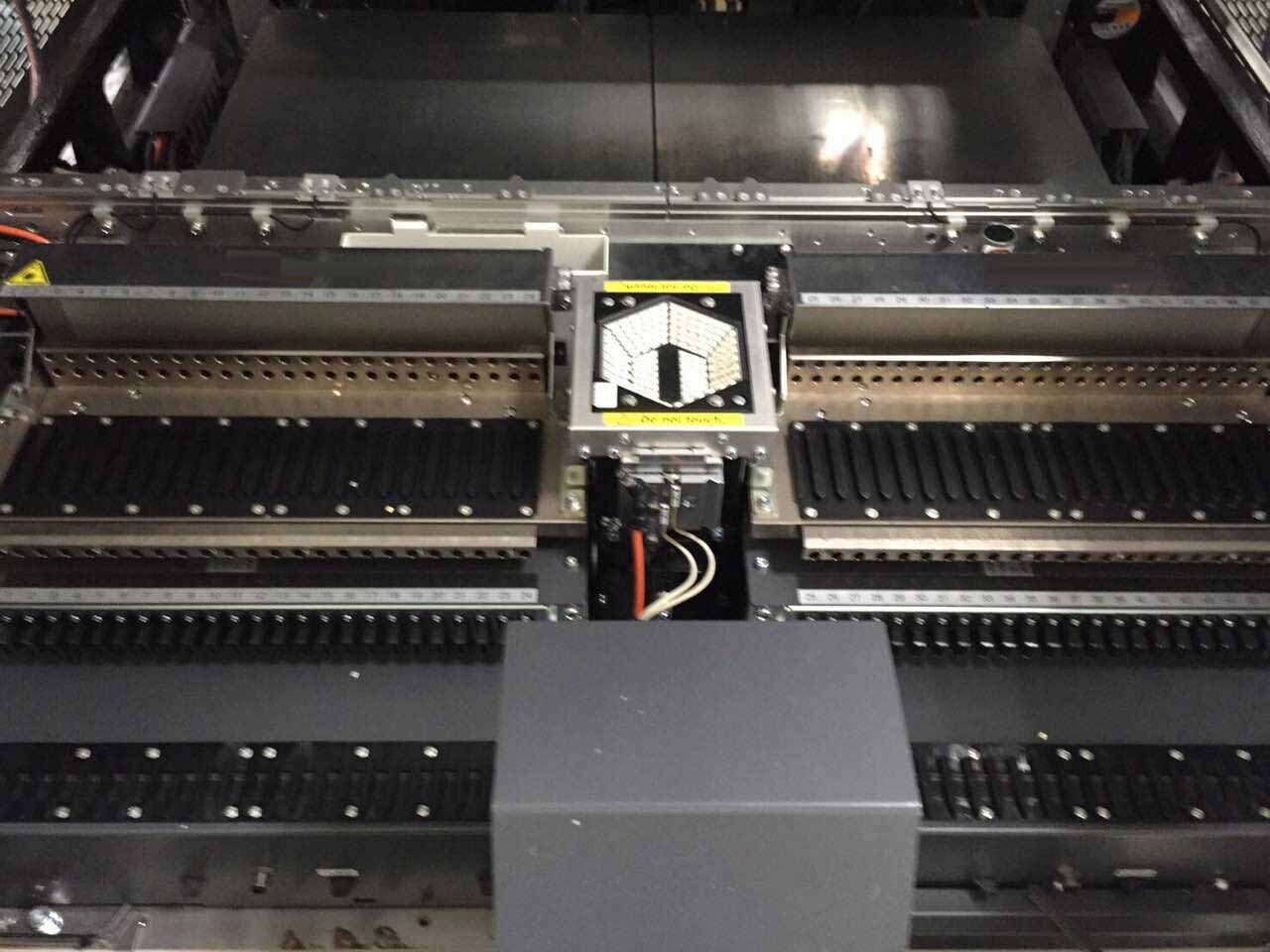

Chip mounter

Fix compact economy flexible modular

(5)MTF Heads

Fixed feeder plate:

Front (48 front, 8 mm feeder / ES (electrical) feeder)

Rear side 60 feeder slots

(5) Nozzle 301A

(5)Pcs of 312A to be selected, For narrow pitch mounting

Conveyor width auto adjustment

Clamp board positioning unit

(2) Splicing reel holder for fixed feeder bank (for 60 feeder positions)

(2) Feeder set-up station on machine

Rear side LCD panel

Tape cutter for feeder carriage 60 positions (built-in type) Front & Rear

2014 vintage.

YAMAHA YS12F is a highly advanced pc board assembly and manufacturing equipment designed for high-volume quality production and minimal maintenance requirements. This system has been proven to be a reliable and cost-effective solution for any customer's production needs. YAMAHA YS-12F is equipped with a fully automated production line, which includes a surface-mount machine, a die-attach unit, an oven, and a test and inspection machine. The surface-mount machine is designed for high-speed solder mounting of small components onto the board. It is capable of placing components with a range of 0402 up to 50mm-wide components. The die-attach tool is designed for die-attach of flip-chip components and BGA package components. The oven features a two-level uniformed heating asset that provides optimal temperature conditions for soldering and reliability testing. The test and inspection model is designed to detect any deficiencies in the board, such as bare wire joints, and to prevent submitted boards from further processing if any issue is found. YS-12 F's production line is monitored by a centralized supervisory computer equipment, which can be used for troubleshooting, maintenance monitoring, and data logging. The system includes an array of sensors that monitor the production line and notify of any faults or operating anomalies. The unit also features a computer board design and assembly library for loading board data and CAD drawings into the production line. In addition, YS-12F includes an operator-friendly interface, which allows for easy parameter setting and machine operation. The tool is also equipped with a host of safety features such as an emergency stop switch, and lead-sensing cameras to prevent personnel from coming in contact with exposed leads. YAMAHA YS-12 F is designed to satisfy the demands of both high-volume and custom production needs. The asset has been engineered to guarantee a high yield rate and ensure the highest quality standard. Furthermore, the model is highly reliable and cost-effective, providing a great value for customers.

There are no reviews yet