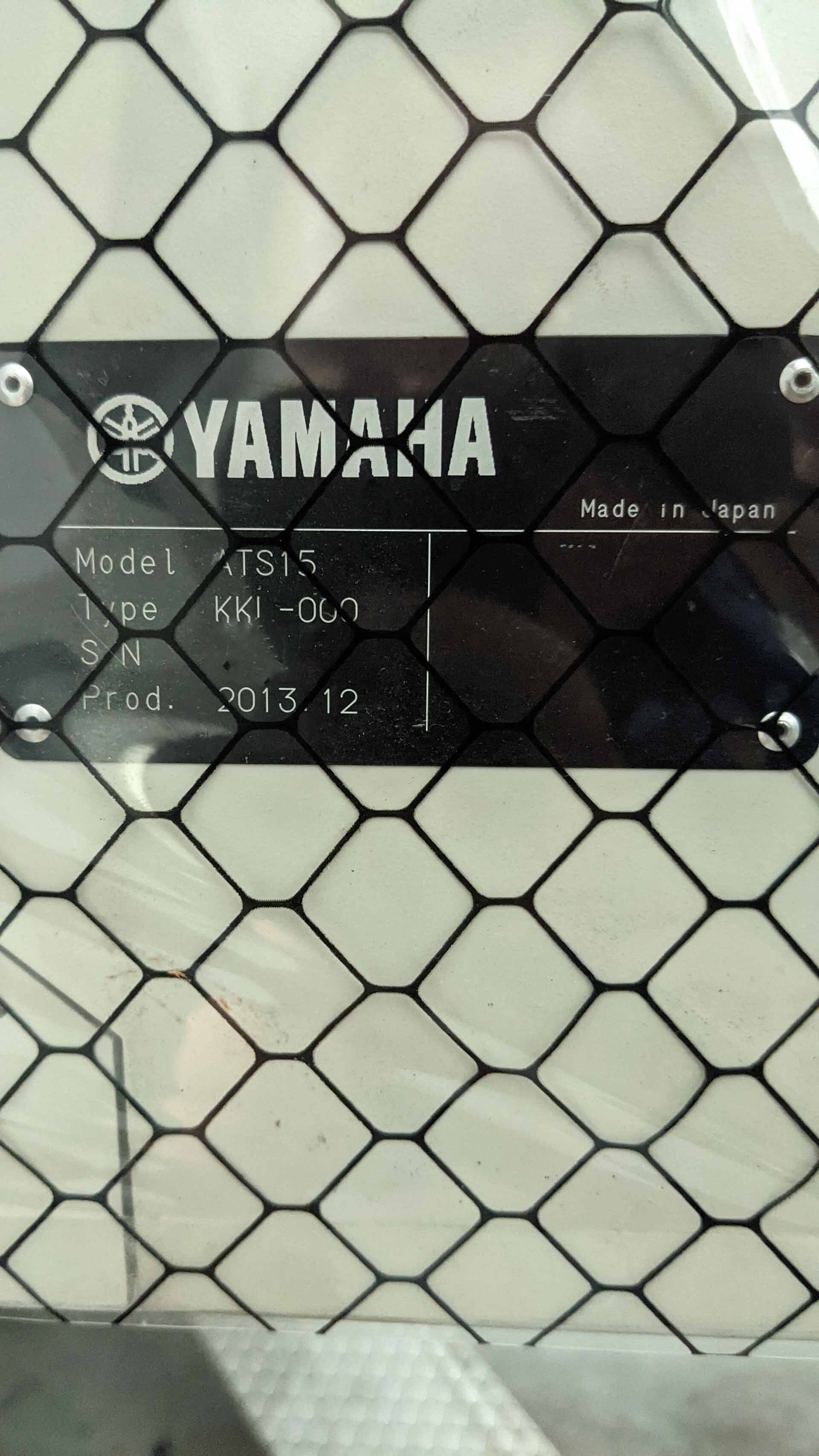

Used YAMAHA YS12F #9392299 for sale

URL successfully copied!

Tap to zoom

ID: 9392299

Vintage: 2013

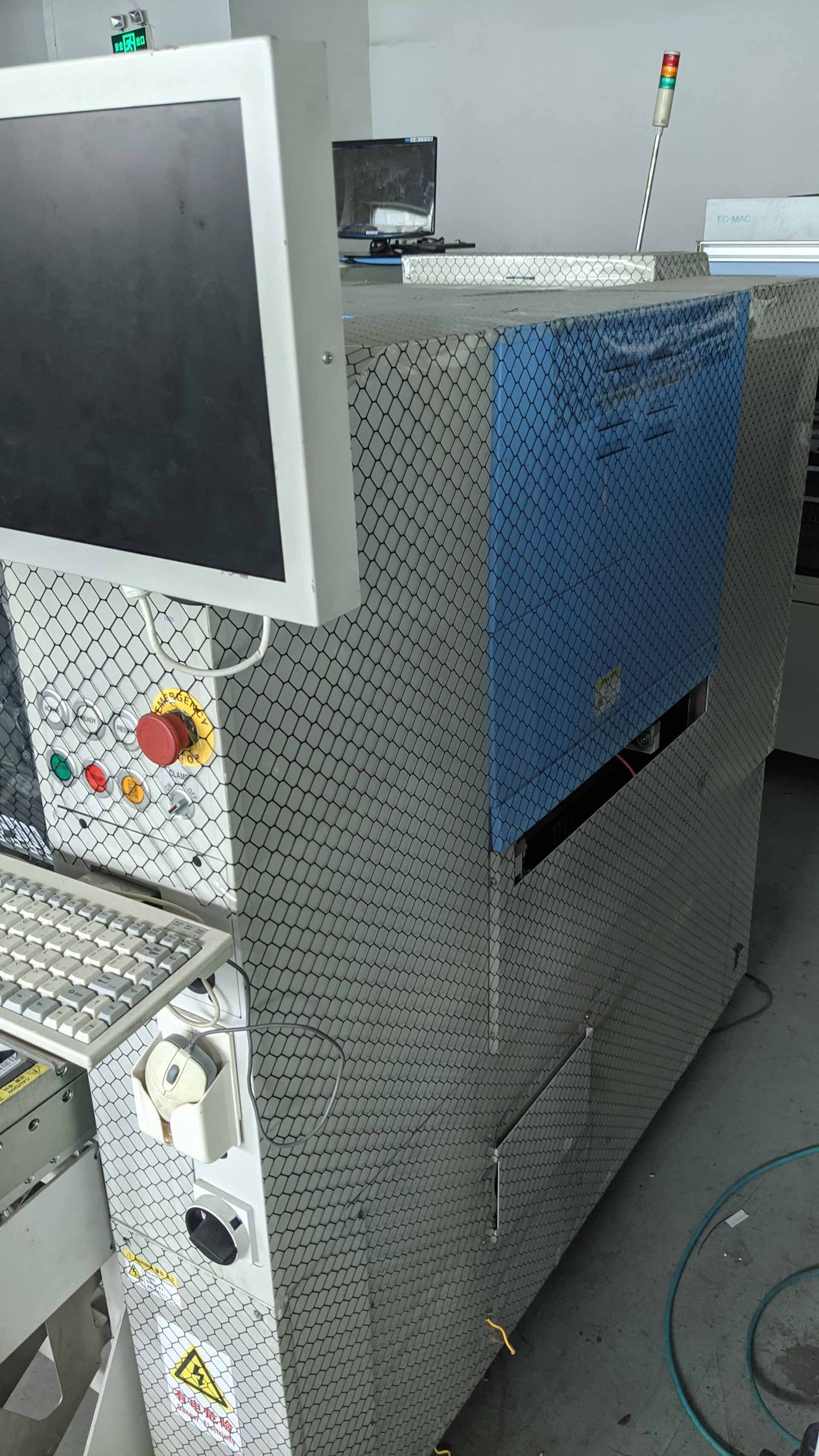

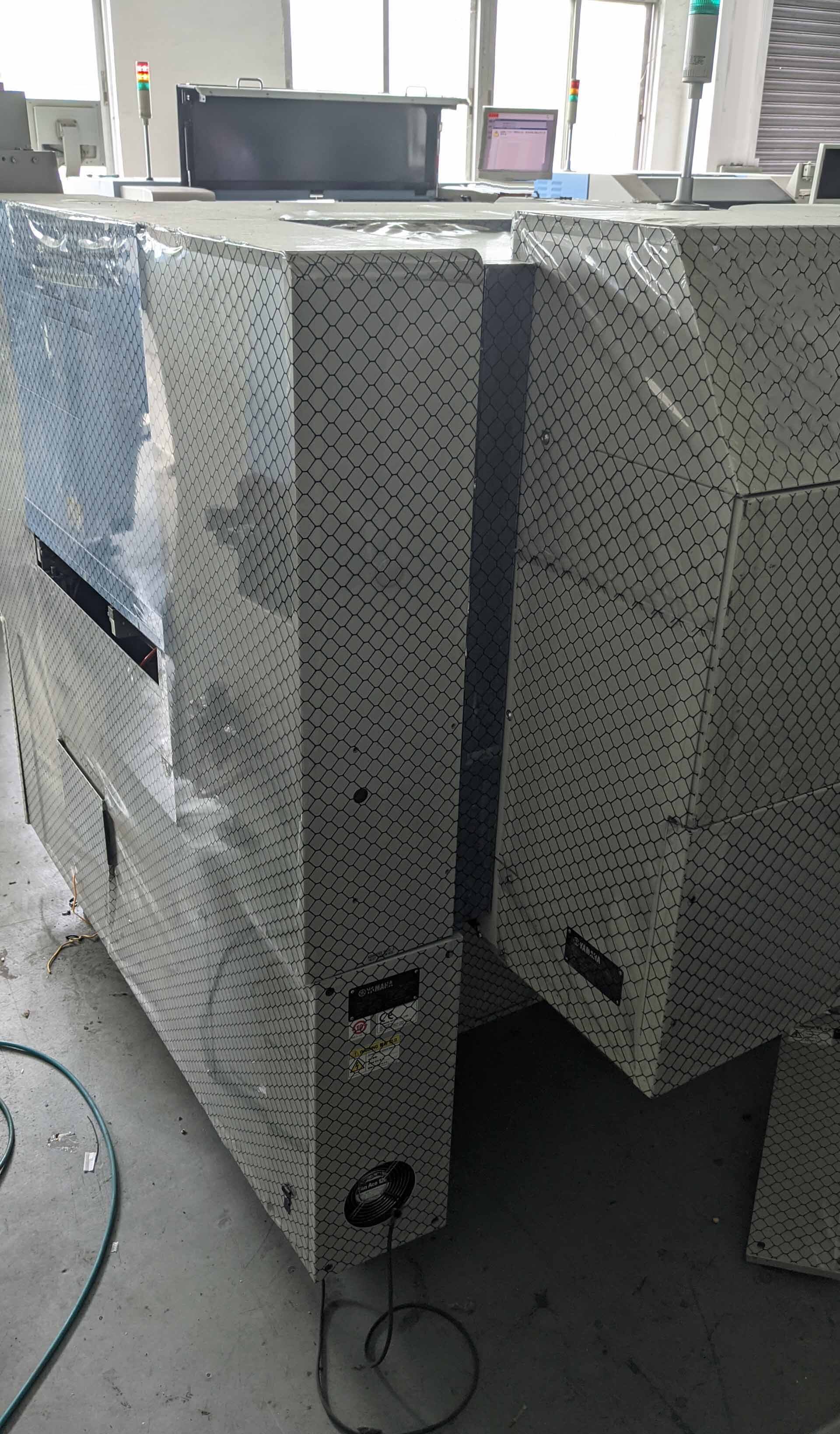

Pick and place machine

With backpack

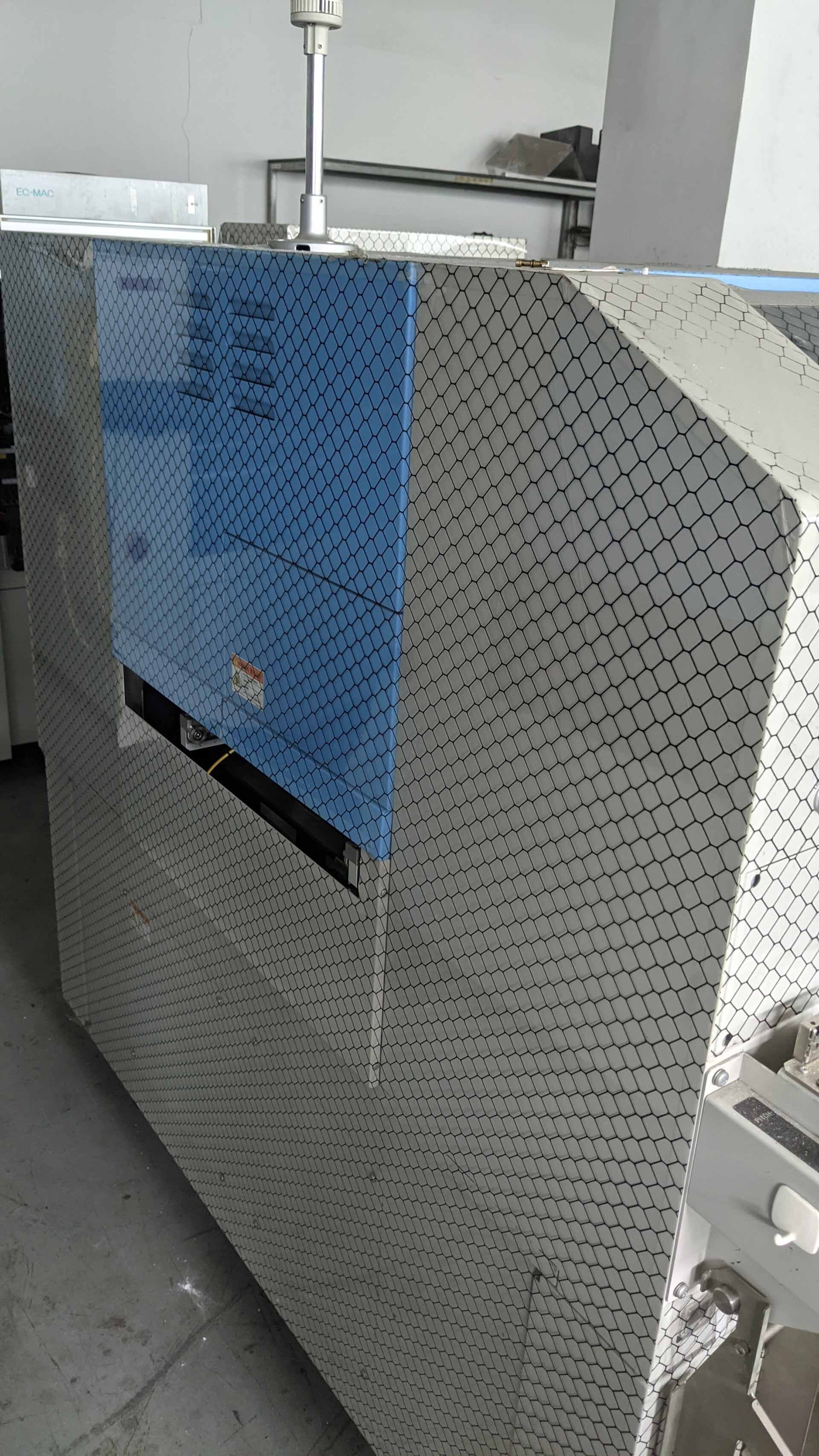

Peripherals / Accessories: YAMAHA AT S15

2013 vintage.

YAMAHA YS12F is a professional quality, pc board assembly and manufacturing equipment made by YAMAHA Motor Corporation. The system itself is highly customizable and cost-effective, allowing customers to tailor it to their exact production needs. It is one of the most reliable and stable production systems in the market. YAMAHA YS-12F offers enhanced performance and high productivity to meet the increasing demand for better quality and advanced technologies. This highly integrated production solution comes integrated with advanced features. It has a powerful motor and an intuitive control panel, which features a touchscreen 7-inch LCD display. The unit features an air bearing machine, feed wheel, and a high precision, servo-driven indexing mechanism. It offers a maximum processing capability of up to 48,000 boards per hour. The tool also features a powerful and programmable vision asset, enabling board manufacturers to perform fully automated lead inspection and form-in-place electronic testing. It includes a robot arm, capable of accuracy and repeatability up to 0.2 millimeters, as well as an optional integrated PC board handling model. The equipment includes an integrated high performance cooling system that works to keep heat within the desired range. This unit comes with a strong customer service team ready to offer setup assistance and technical assistance. With training provided by YAMAHA team, the customer can obtain the support needed to set up and operate the machine. Other features of YS-12 F tool include improved trace diagnosis, full trace rework ability, and allowing high speed line integration. This production asset is designed to be expandable and allows for customization. Due to its versatility and flexibility, it can adapt to any situation with minimal effort. YAMAHA YS-12 F is an excellent choice for companies that need to meet demanding production requirements and improving product quality. It is easy to use, and provides consistent and reliable operation. With its advanced features and versatility, this model can help companies remain competitive and productive in their production processes.

There are no reviews yet