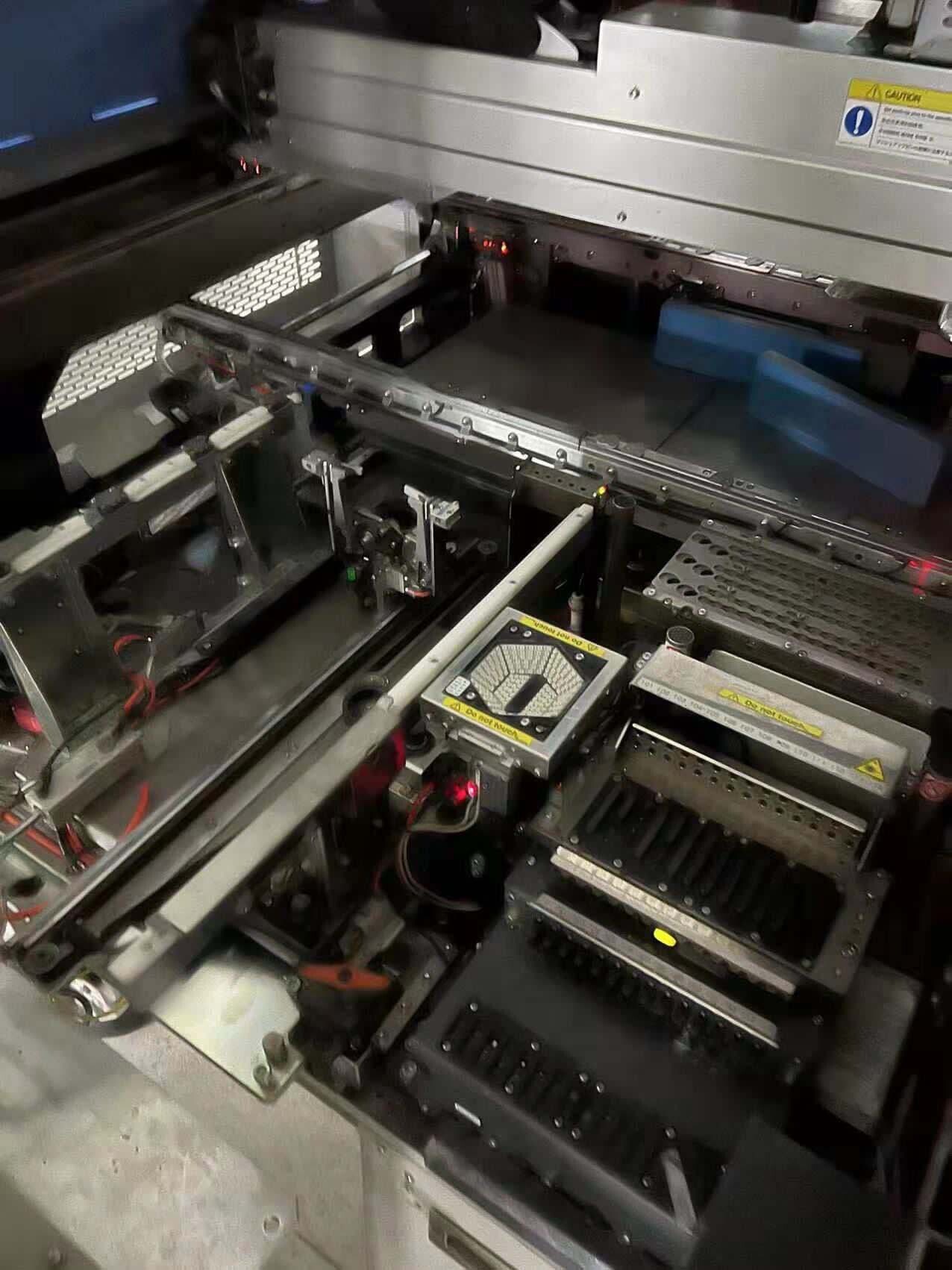

Used YAMAHA YS24 #293597238 for sale

URL successfully copied!

Tap to zoom

YAMAHA YS24 is a high-end PC board assembly and manufacturing equipment designed to provide flexible solutions for assembling and manufacturing multi-layer single and double-sided printed circuit boards (PCBs). It is equipped with state-of-the-art technology, such as an industry-leading vision controller and advanced machine vision system. YAMAHA YS-24 has a user-friendly interface, allowing easy access to its many features. The unit is equipped with a range of advanced tools and functions, including automated component placement and planning, component parameter programming, component checking, component alignment, and component placement monitoring. The machine also features a powerful process monitoring tool which can be used to identify and fix issues with process setup and parameter programming. YS24 is capable of handling up to six component layers and can accommodate sizes ranging from 33mm x 33mm to 860mm x 610mm. It can also handle the placement of components ranging from 0.2mm x 0.2mm to 10mm x 10mm. The asset is capable of assembling component packages up to X-TQFPs (smallest size 0.4mm x 0.4mm). The model is equipped with an integrated temperature/humidity control for optimum component placement and process stability. YS-24 is built with an advanced component placement equipment, allowing for high-speed component placing. The system is capable of placing up to 4000 components per hour with a peak-placing accuracy of +- 0.03mm. The component placement area is illuminated with a bright light, ensuring fast and accurate component placement. YAMAHA YS24 is also built with a range of inspection and monitoring systems, including an automated surface mount inspection (AIS), an in-circuit test unit (ICT), an automated optical inspection machine (AOI), and a laser process monitoring tool. The AIS and AOI systems allow for high-speed confocal inspections of surface-mount components and optical inspections of board layers respectively. The ICT asset enables detailed inspection of circuitry and can detect open, short, excess, wrong, and missing components. The laser process monitoring model allows the equipment to track the process workflow, providing real-time feedback on the accuracy of placement and the soldering strength. The ICT, AOI, and laser monitor system provide a comprehensive process quality control unit. YAMAHA YS-24 is built with a number of advanced control systems, such as an electrical test machine and temperature/humidity control. The electrical test tool can detect shorted, open circuits, and incorrect polarity. The temperature/humidity control asset ensures optimal process stability and component life. In conclusion, YS24 is a powerful and highly advanced PC board assembly and manufacturing model. It is equipped with the latest tools and features, making it ideal for assembly and manufacturing of single and double-sided printed circuit boards.

There are no reviews yet