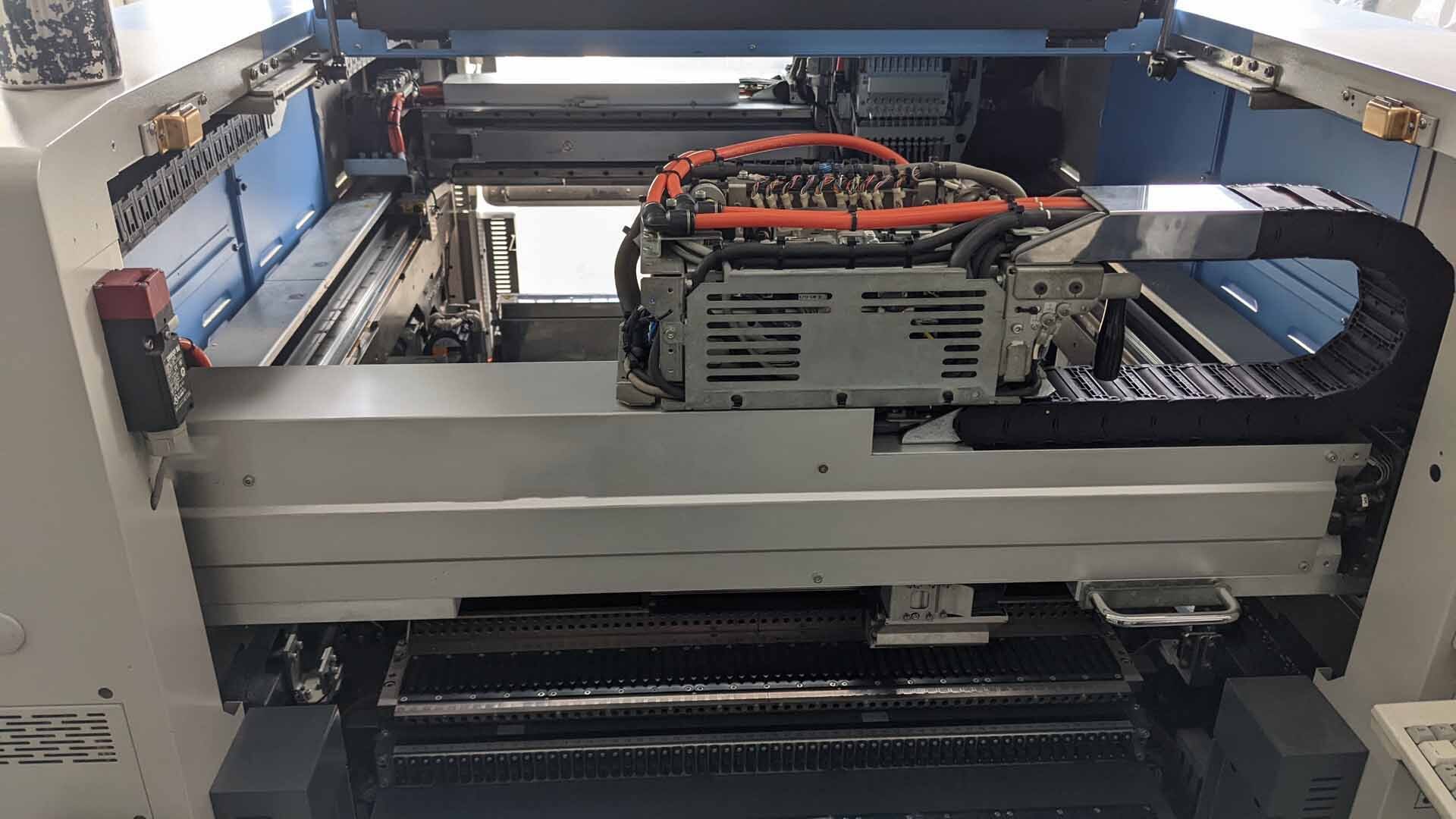

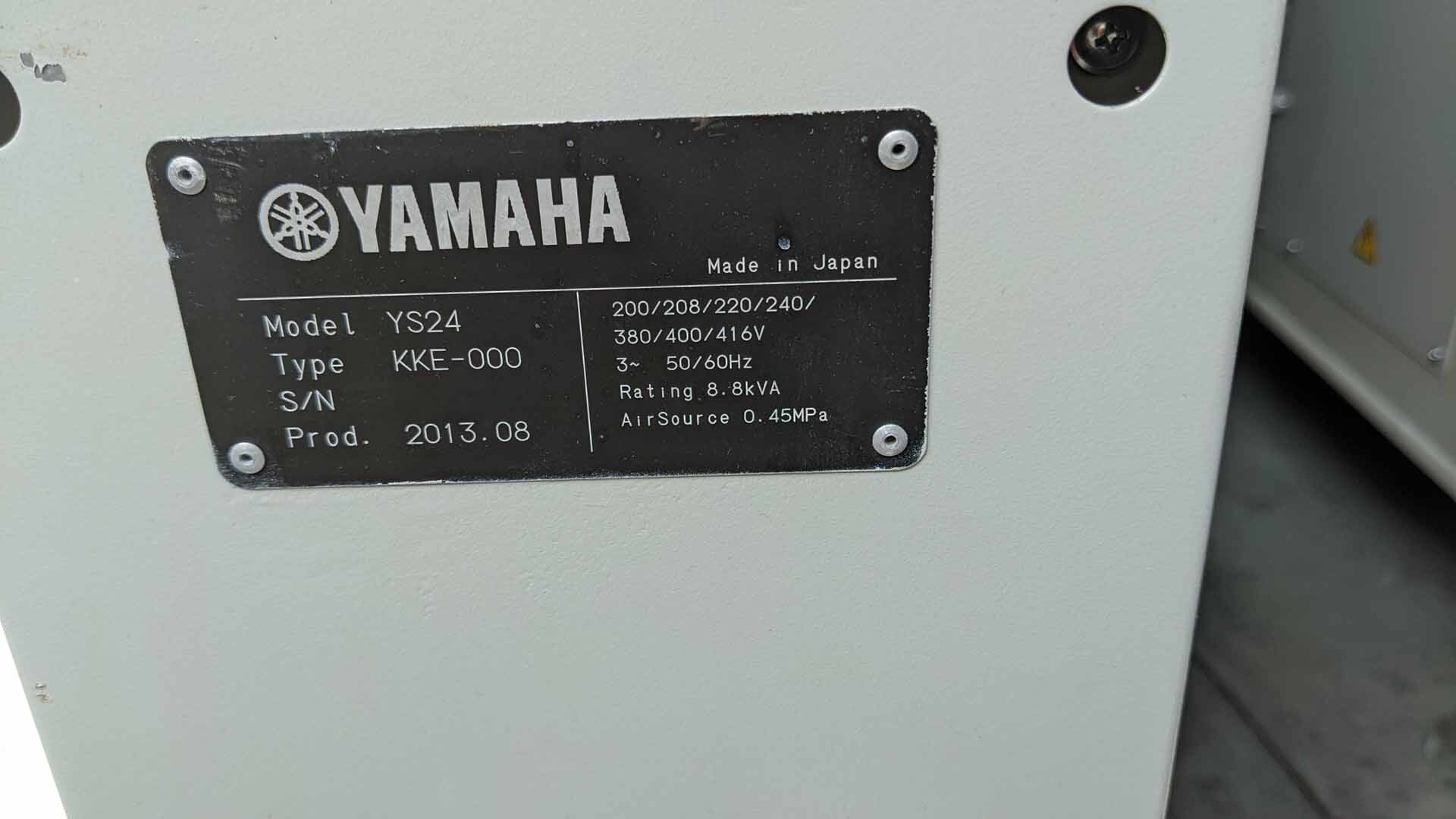

Used YAMAHA YS24 #293648597 for sale

URL successfully copied!

Tap to zoom

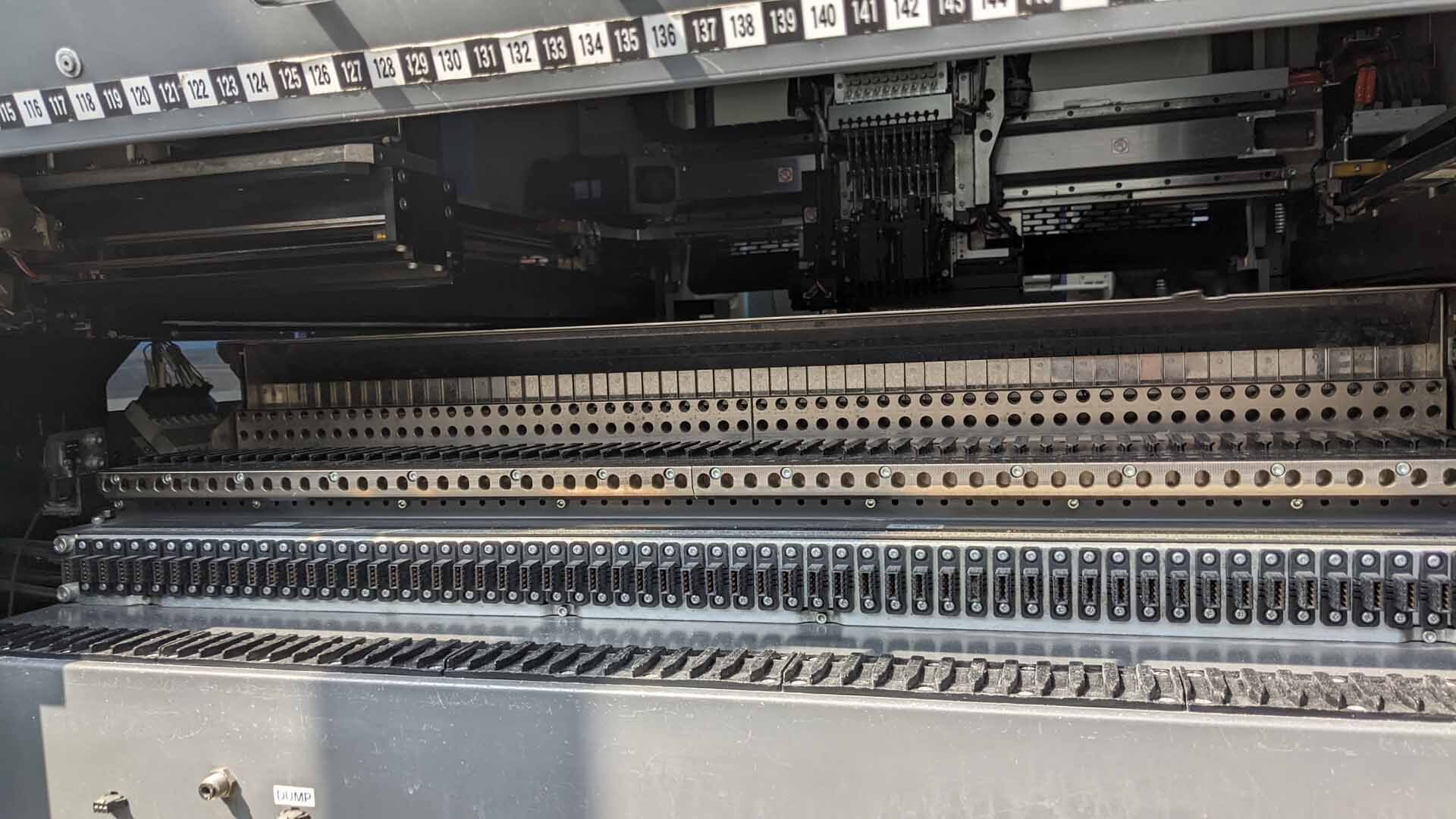

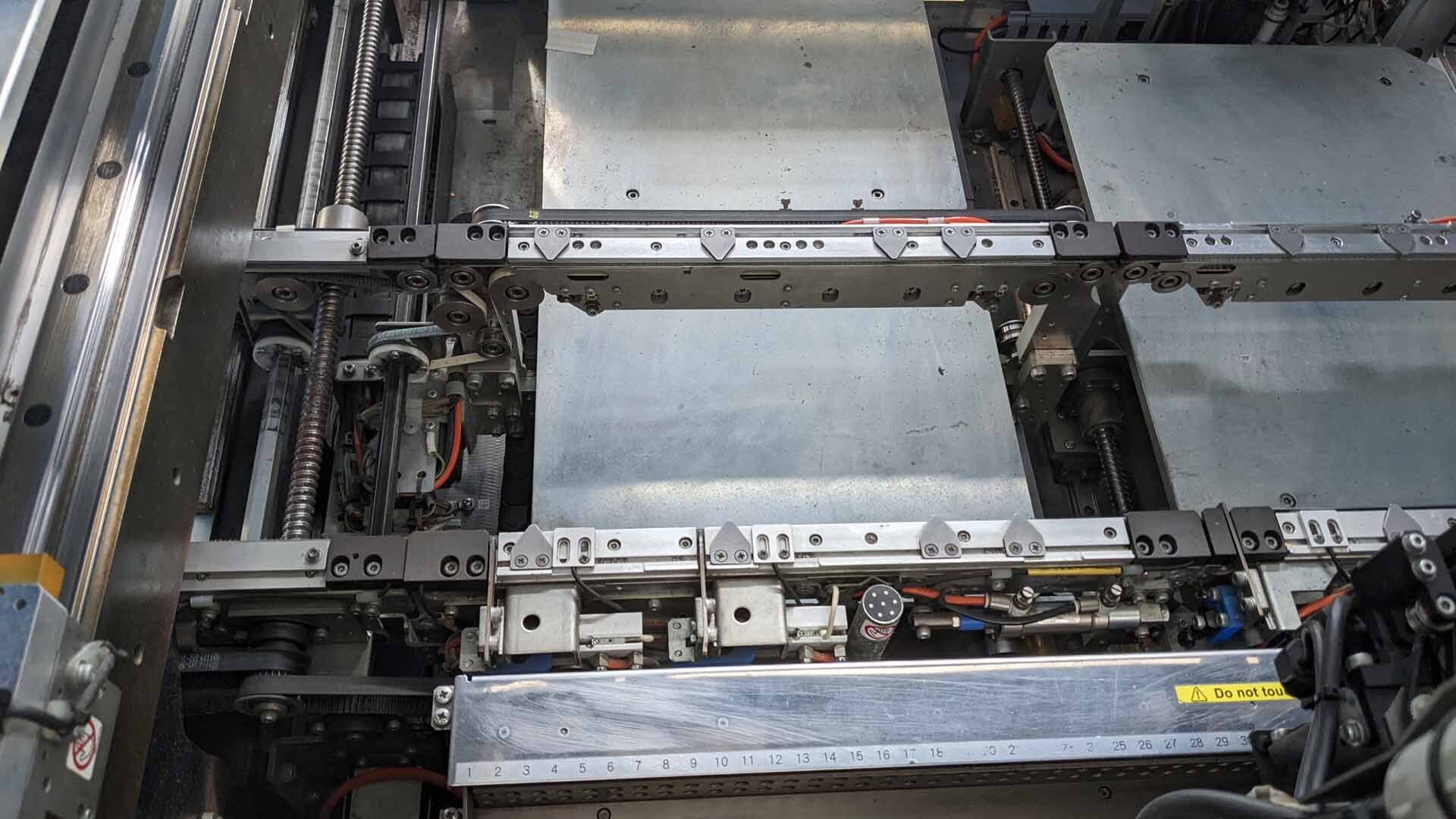

YAMAHA YS24 is a complete PC board assembly and manufacturing equipment. YAMAHA YS-24 is an easy to use, cost effective system that ensures high quality component placement, assembly and programming. The unit has all the features necessary for fast and accurate material feed, component placement, solder paste deposition, and component reflow, enabling manufacturers to quickly produce high-quality and high yield product runs with minimal set-up time. YS24 provides a complete manufacturing solution for PC board assembly needs. It features an integrated CAD/CAM/CAE software suite for design, with automated device design layout that enables quick and accurate component placement. YS-24 can handle assemblies from single to large format boards, plus it can easily handle optical, ball grid array (BGA) and conventional components. The machine includes a high-speed vision tool to automatically detect and locate parts on the board. This vision asset also provides automated device mapping, allowing the model to identify the elements on a board accurately, improving efficiency and reducing manual handling. YAMAHA YS24 uses several advanced technologies to ensure consistently high-quality output. These include ultrasound cleaning, automated paste optimizing, and laser conformal coating. In addition, it has various components to ensure that components are placed accurately and securely, including multiple feeders, vision guided robotic placement systems, and a dual-camera equipment to ensure that materials are placed in the correct locations. YAMAHA YS-24 also has a fully integrated reflow soldering system, which uses multiple furnaces and accurate temperature control to ensure the delivery of a soldered product with high reliability and repeatability. Finally, it has a full software suite for programming microcontrollers and integrated circuits, allowing for updates or customization. YS24 comes with a variety of features to further enhance the convenience and accuracy of the manufacturing process. These features include a real-time job scheduling unit to keep track of components, materials and production status, multiple palettes for increased material loading, and a share port link machine to allow remote maintenance and control. In addition, YS-24 has an automated assembly process control tool which allows easy tracking and documenting of processes and cost-effectively provides real-time process data collection and analysis. YAMAHA YS24 is an ideal asset for manufacturers who need a fast and efficient solution for PC board assembly and manufacturing. With its ability to handle multiple board sizes, as well as its automated device identification and placement, it enables manufacturers to quickly and efficiently produce high-quality products. In addition, its comprehensive software suite, automated process control and job scheduling model, and range of features make it an ideal equipment for speed and efficiency.

There are no reviews yet