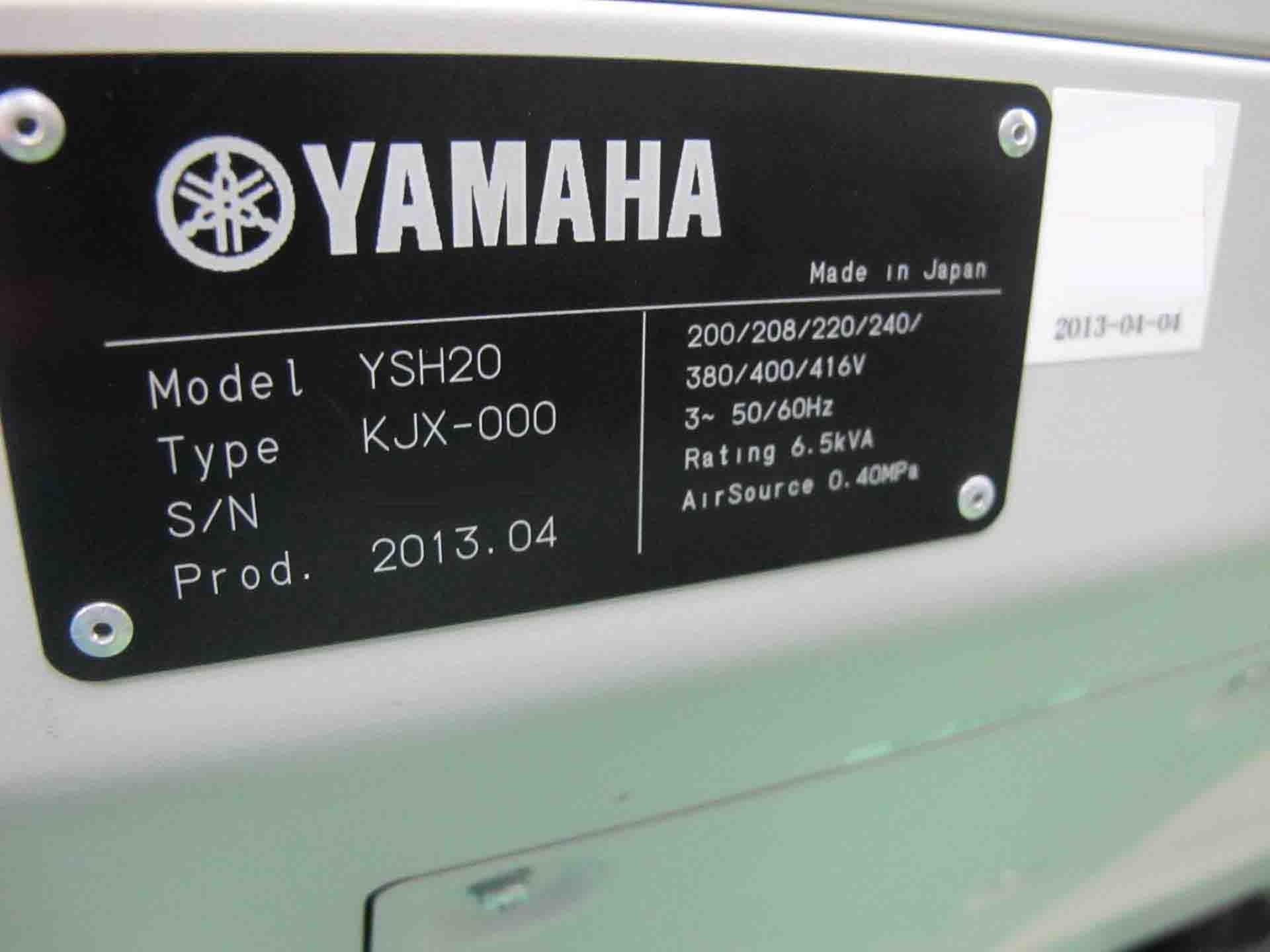

Used YAMAHA YSH20 #9200552 for sale

URL successfully copied!

Tap to zoom

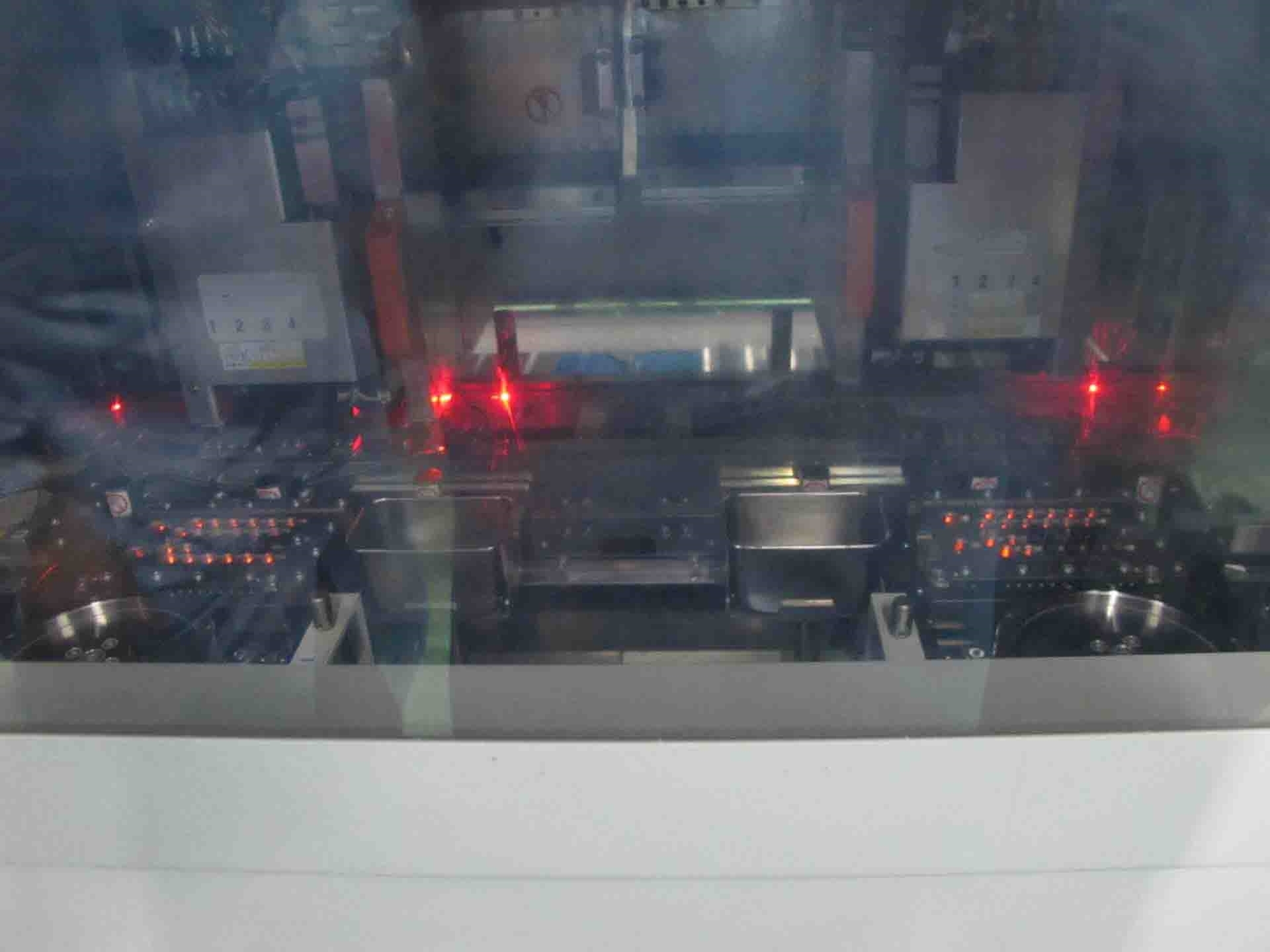

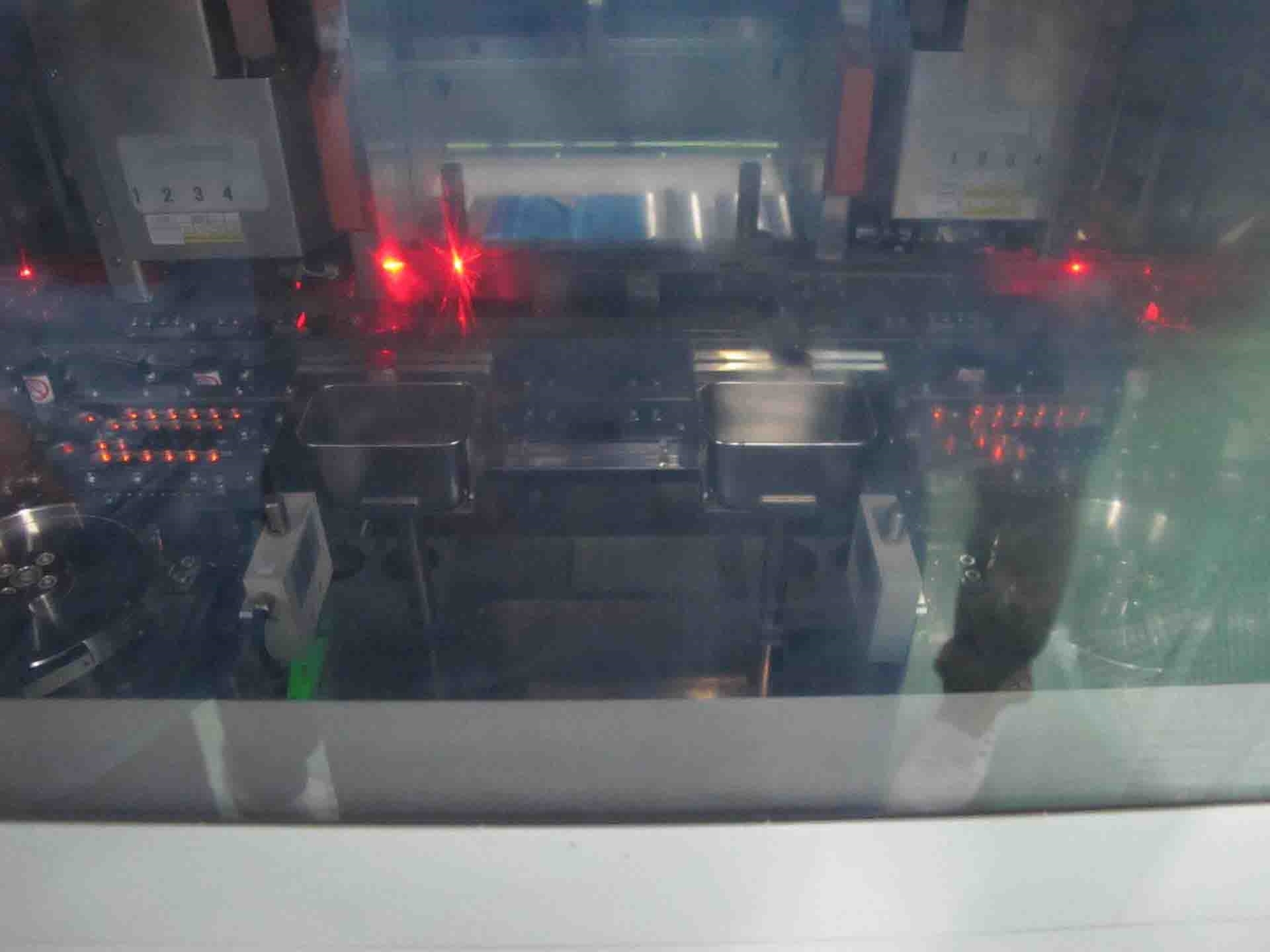

YAMAHA YSH20 is a PC board assembly and manufacturing equipment built to allow for high-precision, high-speed assembly of boards with a high-level of accuracy and repeatability. The system combines a fully automated computer-controlled drive unit with an advanced vision inspection machine and sophisticated software algorithms to accurately place various components on each board. The tool is designed to provide a high-precision and high-speed asset that can process boards quickly and flawlessly. The computer-controlled drive model provides precise placement of the individual components on the board. An integrated vision equipment inspects each component to ensure accuracy and quality. Components are loaded and unloaded automatically and tracking software tracks the progress of each board. This system provides a reliable and efficient way to automate the assembly of boards with a high degree of accuracy and repeatability. The software used in YSH20 is designed to aid in the placement of components on the board. The software can be programmed to identify various component types and accurately place them in the correct position on the board. The software can also be used to track the progress of each board and provide an immediate feedback unit to detect any abnormalities. YAMAHA YSH20 is equipped with an advanced vision machine that is designed to detect the orientation and accuracy of the component placement. The vision tool is able to detect variances in component placement as small as a few hundred microns, which is below the human eye's visibility threshold. The asset can also detect any component issues such as bent or damaged pins and will alert the operator to take action to prevent errors from occurring. YSH20 is designed to save time, reduce costs and improve quality. The model is designed to provide a high-speed approach for accurate board assembly with minimal operator intrusion. The equipment is designed to deliver high accuracy, repeatability and reliability. The system is able to quickly and accurately identify components and secure them in the desired locations, providing a reliable and efficient way to assemble boards.

There are no reviews yet