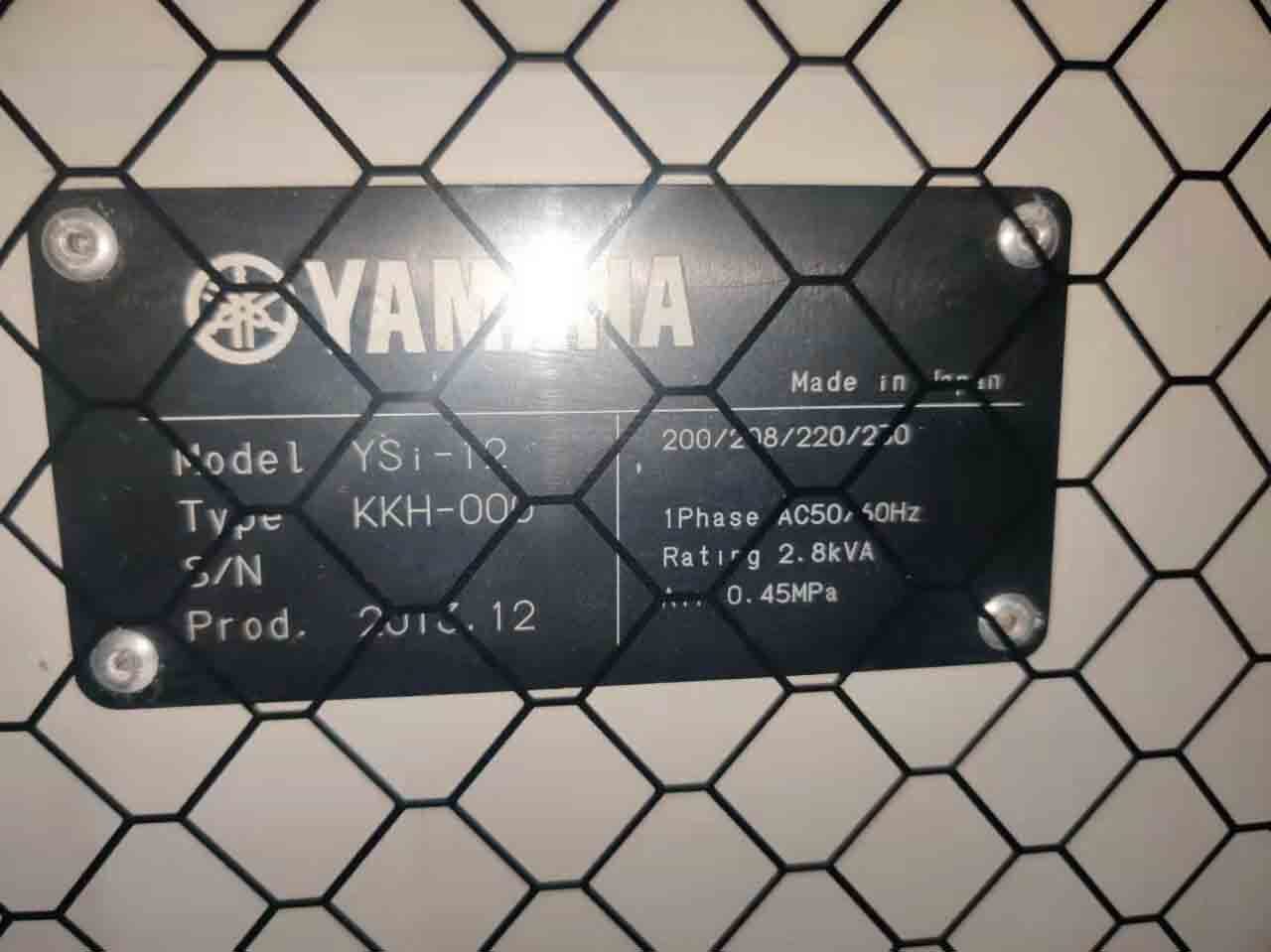

Used YAMAHA YSi-12 #9411841 for sale

URL successfully copied!

Tap to zoom

ID: 9411841

Vintage: 2013

Automated Optical Inspection (AOI) system

Model: KKH-000

High resolution:

XY: 10μm

Z: 5μm

Target substrate: L 780 × W 460mm (maximum)~L 50 × W 50mm (minimum)

Inspection speed: L 330 × W 250mm per substrate, 15 seconds (3-Layer illumination)

Resolution 19μm: 44.6 × 37.4mm/view

Visible light (Red / Green / Blue)

Infra-Red (Infra-Red): 19μm/10μm/5μm

Laser (height): 5μm

Power specification: Single-phase, AC200/208/220/230V, ±10% 50/60Hz

Air supply source: > 0.4MPa

2013 vintage.

YAMAHA YSi-12 is a fully integrated and automated pc board assembly and manufacturing equipment from YAMAHA Robotics. It offers flexible, high-throughput production of printed circuit boards (PCB)s. YSi-12 has a single, manually loaded cart-type device that inspects, deposits and assembles components onto the surface of the PCB. YAMAHA YSi-12 is a four-axis robot, capable of processing up to 12 PCBs simultaneously for increased efficiency. YSi-12 features a fast, intuitive programming menu that allows the user to configure the exact parameters needed for the process. Its advanced High Accuracy Inertial Compensation (HCI) technology compensates for part shape, position and orientations of components along each of the four axes, further improving accuracy and repeatability. This system also includes an on-board vision recognition unit that quickly recognizes different component elements and sizes. YAMAHA YSi-12 is compatible with both multi-sized parts supply tapes and Component Support Modules (CSMs). The CSM units provide a storage tray, where multiple CSMs can be loaded quickly, converted and loaded directly onto YSi-12's transport belt. This machine also reduces the risk of operator error when loading components onto the PCB, allowing for smooth production flow. YAMAHA YSi-12 has a self-contained particle detection tool that detects and removes any contaminants that enter the production line. This ensures the highest quality PCBs are produced and provides reliability for the customer. YSi-12 utilizes dual head pick-and-place units that can handle multiple components at high speeds. It also features a high-speed vacuum nozzlehead that can rapidly transfer parts from tape or tray to board. This asset also has an on-board optical recognition model that detects and recognize shift misalignment in parts and adjusts accordingly. YAMAHA YSi-12's User Interface (UI) offers simple and intuitive operation, including editing of program parameters, setting up of machine cycles, monitoring of process screens, and tool change management. This equipment also allows for easy retrieval of production history and log data. YSi-12 is enclosed for improved safety of operation, and offers a high level of noise reduction. YAMAHA YSi-12 is an ideal solution for PCB Assembly and manufacturing that offers high-speed production, high reliability and accuracy, and an intuitive UI. It offers cost-effective and efficient performance, making it an ideal choice for the modern assembly and production line.

There are no reviews yet