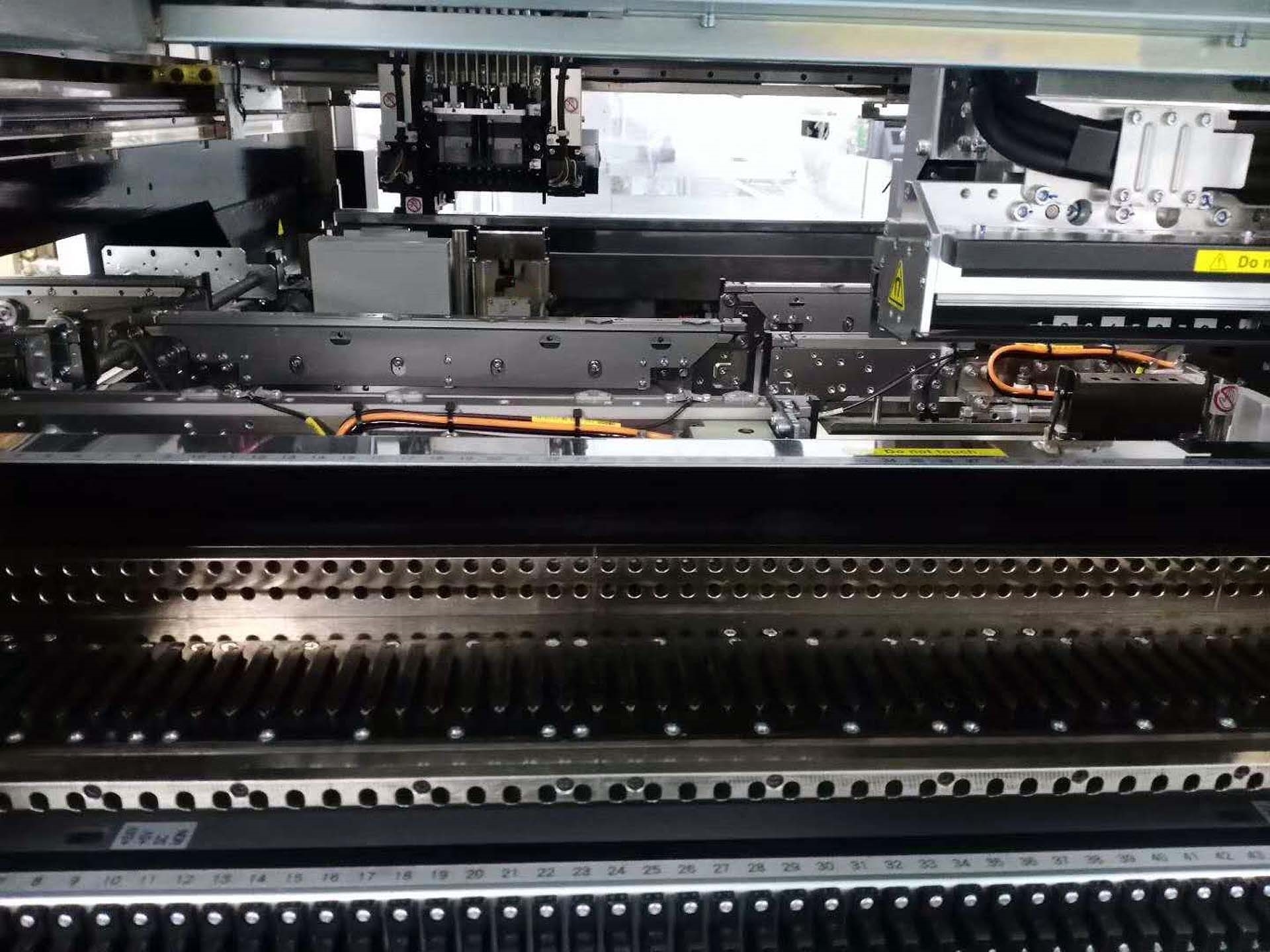

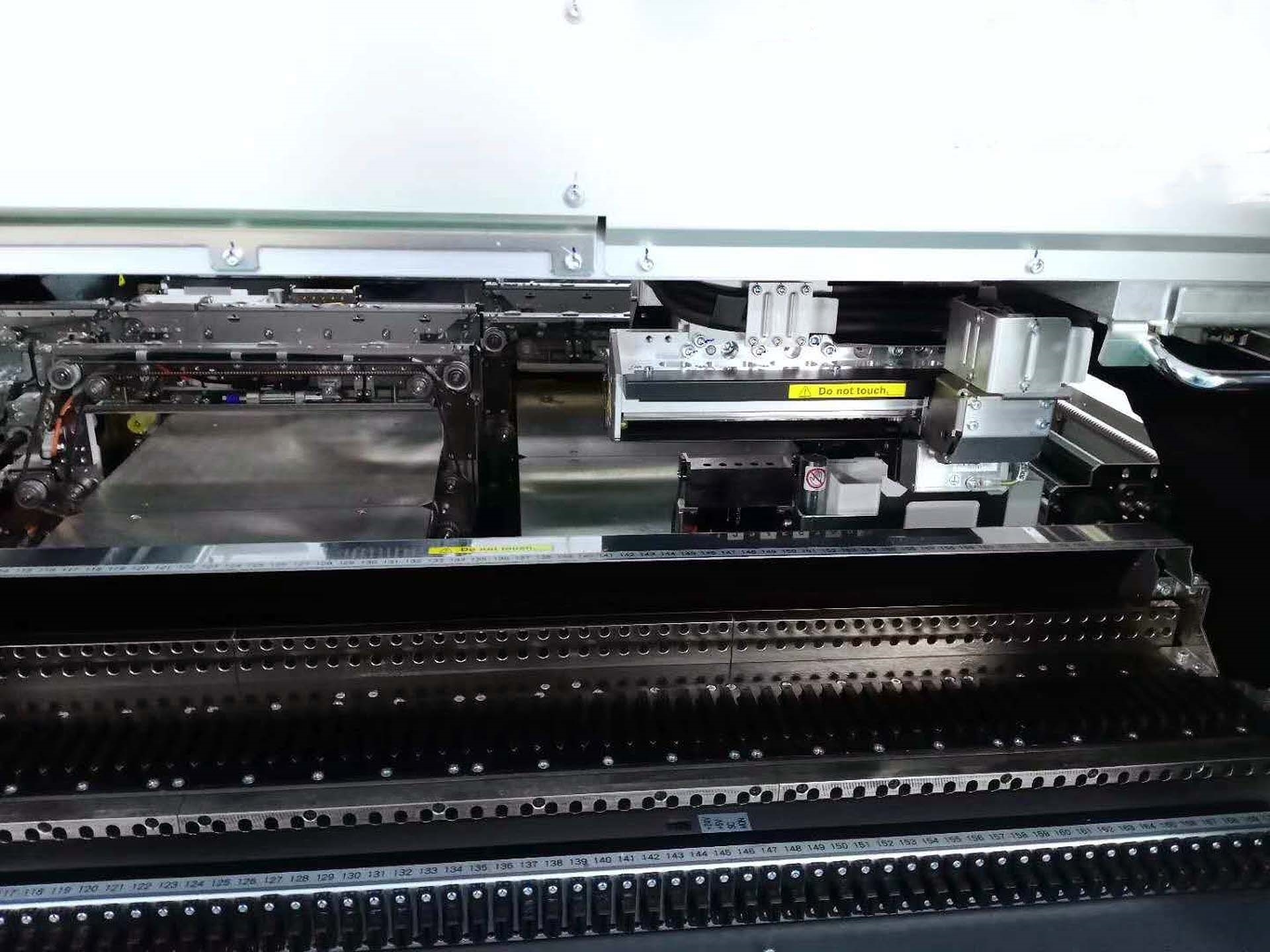

Used YAMAHA YSM20 #9296674 for sale

URL successfully copied!

Tap to zoom

ID: 9296674

Vintage: 2019

Pick and place machines

Working hours: 5000

Left to right

(2) Heads

2019 vintage.

YAMAHA YSM20 is an automated pc board assembly and manufacturing equipment developed by YAMAHA Corporation. It is designed to work in a fully automated manufacturing environment, providing high-precision assembly of electronic components onto pc boards. The system is composed of several components, including an SMT placement head, an AI Solder Paste Printing (SPP) unit, a vision-based inspection machine, and an automatic insertion machine. The placement head used in YAMAHA YSM 20 is able to accurately place and transport SMT components from a component supply track to the exact location on the pc boards. It is equipped with two high-speed, high precision motors which enable it to move components at speeds up to 7500mm/s with a maximum tolerance of ±20 μm. The use of 6-axis control and vector recognition technology also allows it to accurately and quickly place and transport the components with minimal material wastage. The AI Solder Paste Printing (SPP) tool is a highly reliable paste printer in which all paste calculations and measurements are controlled by a neural network. It contains several smart features, such as automated measurement of the size and shape of the component for accurate printing, three-dimensional pans detection for joint detection, and control of the pressure and quantity of the paste. This allows for a more accurate and efficient paste printing process. The vision-based inspection asset is used to inspect, detect, and classify various types of defects, including sewing/joint defects, surface defects, and cross-sectional defects. It is equipped with a high-precision camera that is capable of accurately capturing the mosaic of pc boards and components. The model also contains various algorithms which enable it to detect various defects that could otherwise not be seen by the human eye. The automatic insertion machine is used to insert a variety of components, including IC chips, resistors, and capacitors into designated positions on the pc boards. It is equipped with a high precision gripper and screw-driving equipment which enable it to accurately and quickly insert components with minimal material wastage. YSM20 is designed as a high-precision, fully automated pc board assembly and manufacturing system. Its components are designed to work together to ensure accurate and efficient assembly and manufacturing of pc boards with minimal material wastage. The use of technologies such as AI Solder Paste Printing (SPP), vision-based inspection, and automatic insertion machine allow for further optimization and precision in the assembly process.

There are no reviews yet