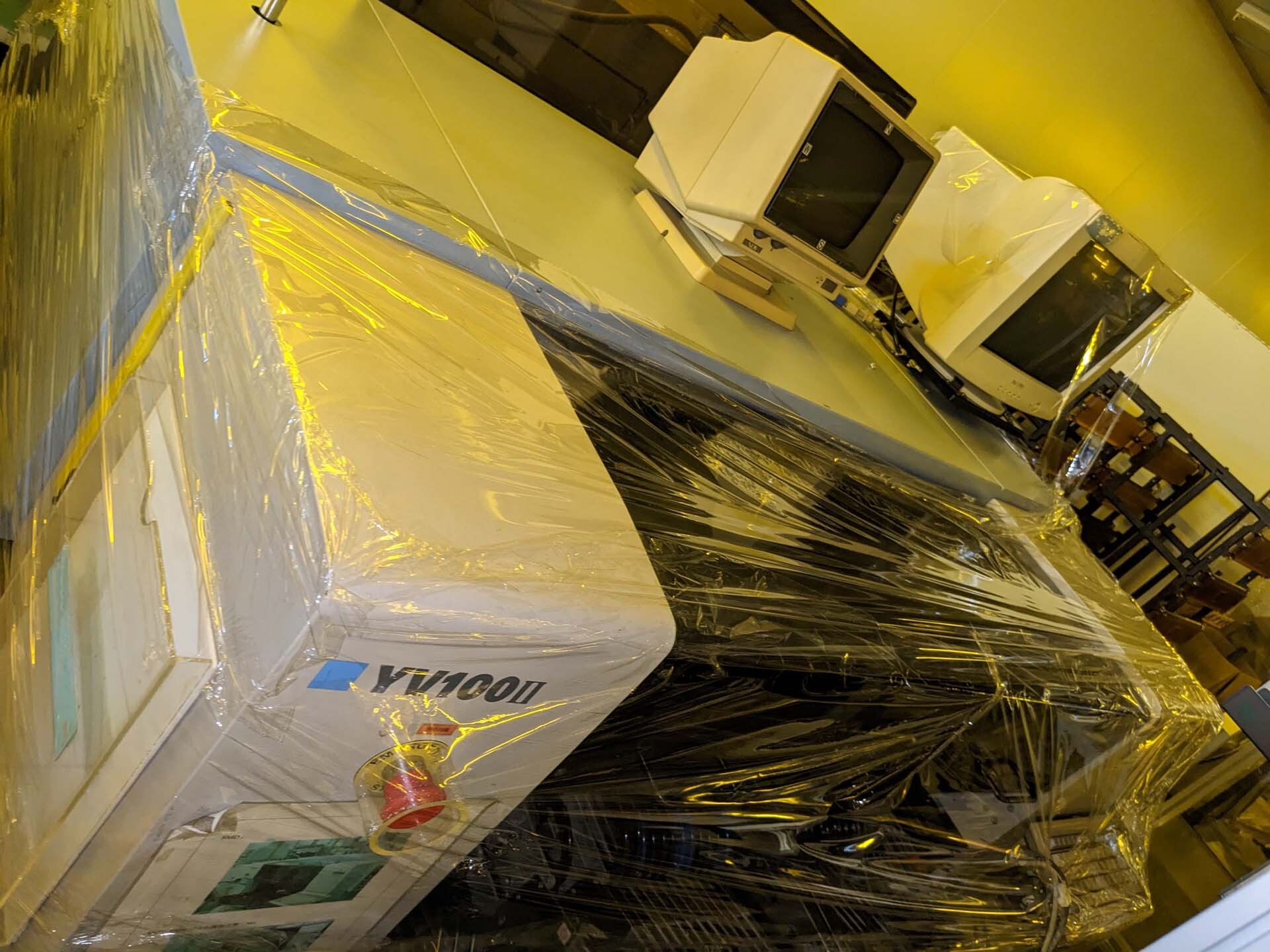

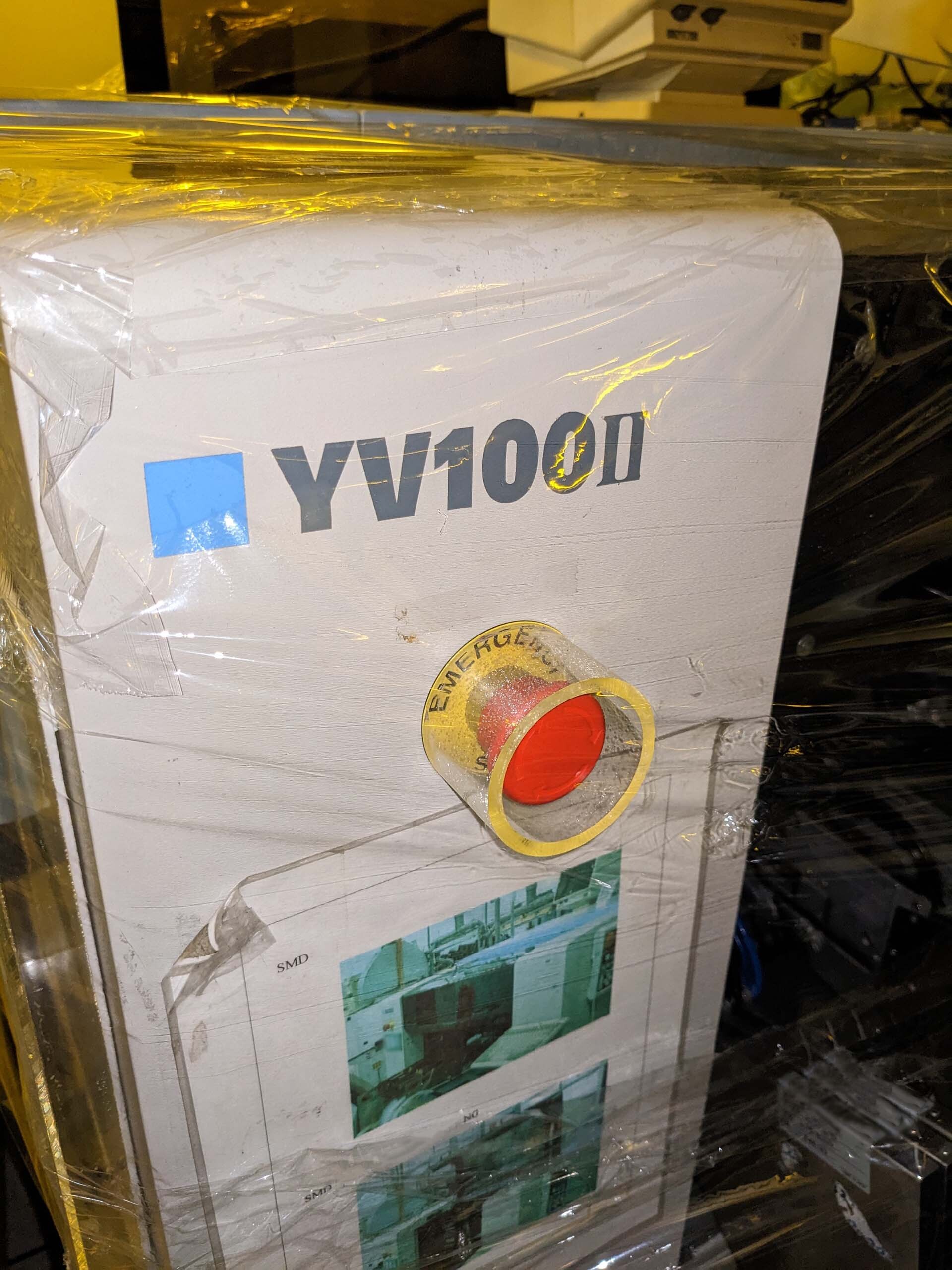

Used YAMAHA YV-100 II #293668371 for sale

URL successfully copied!

Tap to zoom

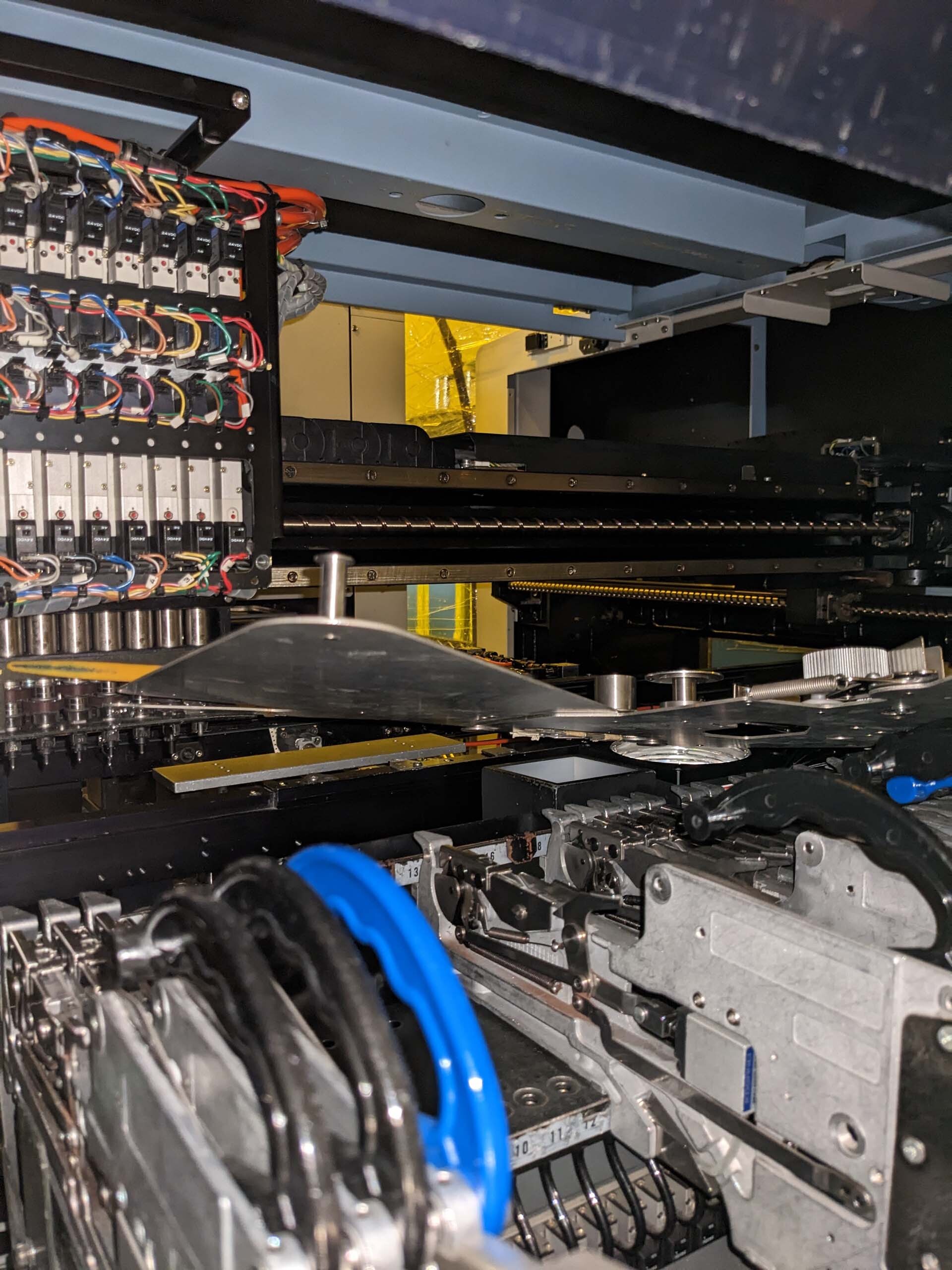

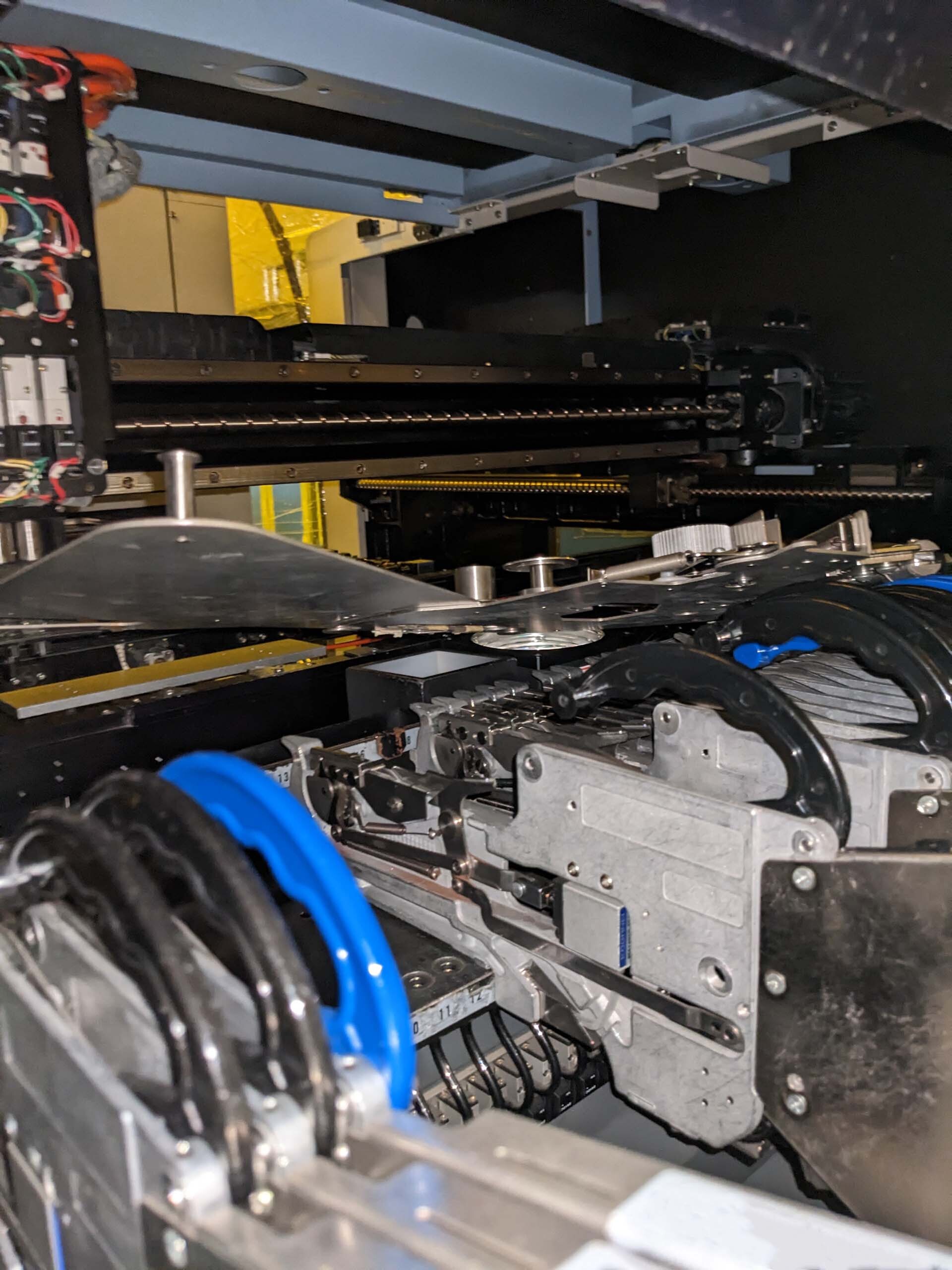

YAMAHA YV-100 II is a PC based board assembly and manufacturing equipment designed for the production and assembly of complex electronic components. It combines automation, cost-efficiency, and flexibility with rapid prototyping capabilities. The main features of YAMAHA YV100-II are: a highly advanced Machine Vision System, capable of capturing readings of PC boards; a component placement unit which consists of a high speed vision based station, an assembly-unit station and a feeding/handler unit; a soldering machine that is designed to meet today's stringent quality requirements; and a PC-based software suite for controlling the parts assembly and placement process, as well as providing data logging, safety interlocks, and various other functions. YV-100II is designed for flexibility, allowing for a variety of PC board sizes and configurations to be used. It can also accommodate multiple SMT components with a wide range of surface mount technologies on the same board. The machine vision tool is capable of capturing and submitting component characteristics to the software, with an accuracy of up to 0.5mm. The component placement asset of YAMAHA YV-100II consists of high speed vision based station, assembling unit station, and an automated feeding/handler unit. The station motions are controlled using servo motors, allowing for precision and reliable component placement. The vision based station is used for locating components on the board being processed and is adjustable to meet various pitch requirements. The assembling unit station allows components to be picked up directly after it is retrieved by the vision based station. The feeding/handler unit is for dispensing components while the model is in operation. YV100 II also features a highly advanced soldering equipment that is designed to meet today's stringent quality requirements. The system is capable of setting up multiple soldering parameters and temperature profiles to meet various formulations of solder, as well as providing pinpoint accuracy and repeatability. YV-100 II is operated using a PC-based software suite that provides the user with an intuitive and user friendly interface. The software has the ability to control the parts assembly and placement process, as well as providing various other functions such as data logging and safety interlocks. It also has the capability to provide traceability of components and assemblies with an auto-tracing feature for recording work in progress. This helps in ensuring that the entire operation is according to PC board Standards. YV100-II is designed to deliver consistent and reliable performance, with minimal operator involvement, allowing for various investments in automation to be made. It is capable of providing significant cost savings with reduced labor costs and higher yields. Owing to its high speed, accuracy, and reliability, the unit is the perfect solution for those looking for a reliable and cost-efficient board assembly and manufacturing machine.

There are no reviews yet