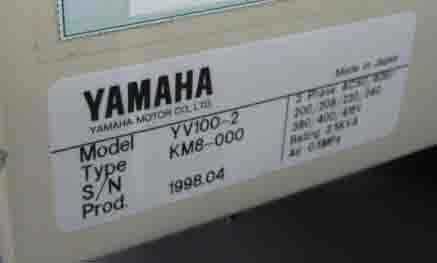

Used YAMAHA YV-100 II #9089210 for sale

URL successfully copied!

Tap to zoom

ID: 9089210

Vintage: 1998

Chip mounter

Right to Left (Front rail fixed)

Type: KM8-000

(55) Feeders

(2) Feeder changing carts

8 in a line standard head

Auto Nozzle change station

Single recognition camera

45,000 working hours

1998 vintage.

YAMAHA YV-100 II is a comprehensive, next-generation PC Board Assembly and Manufacturing System for PCB prototyping and small-to-medium-volume PCB production. It is designed to provide cost-effective, streamlined assembly capabilities for lower-volume applications. YAMAHA YV100-II is capable of producing up to 10,000 placements per hour, with a placement accuracy of 0.01 mm and an IPC-A-610 Class I accuracy rating. The system was designed for speedy setup and changeover, and its large capacity will support boards up to 560 x 510 mm in size. YV-100II features automatic component placement and supports 0603 to large component placements. It is also capable of handling fine-pitch components as small as 15 mils pitch. The machine has a number of advanced features, such as component pre-alignment, component recognition, and component pickup. It also supports a variety of nozzle types and can pick up components from matrix trays, component reels, or insulation paper tape. YAMAHA YV-100II also offers integrated soldering capabilities, with a choice of three soldering tools: a digital hot-air reworking tool, an infrared reflow soldering tool, and a soldering iron. The soldering tool is supported by a multi-stage auto-tinning solder paste application feature. YV-100-II is also equipped for dispensing, with up to 4 dispensing ports available, enabling both water-soluble and non-water-soluble syringe-type or bottle-type adhesives. The touch-screen interface of YV-100 II is both intuitive and user-friendly. It provides a graphical, menu-based operation platform, as well as the ability to store setup data and programs, enabling quick process changeover. The machine features a number of tools and utilities that assist in programming, such as real-time observation of the placement process and the ability to check the placement accuracy. YV100 II is a reliable and efficient PC Board Assembly and Manufacturing System, designed to provide cost-effective assembly solutions for low to medium-volume production requirements. It is capable of automated component placement, soldering, and dispensing, and its large capacity supports boards up to 560 x 510 mm in size. With its intuitive touch-screen interface, advanced features, and programmable utilities, YV100-II is an ideal solution for PCB prototyping and small-to-medium-volume production.

There are no reviews yet