Used YAMAHA YV-100 XG #147392 for sale

URL successfully copied!

Tap to zoom

ID: 147392

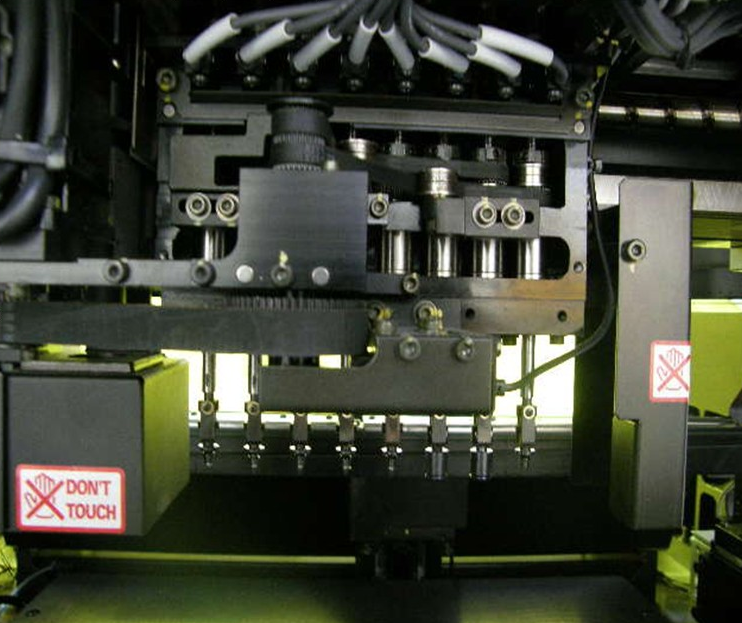

Chip mounter

PCB dimensions

M type: L460xW335mm (Max) / L50xW50mm (Min)

L type: L460xW440mm (Max) / L50xW50mm (Min)

Mounting accuracy

Absolute accuracy (μ+3σ): +/-0.05mm/CHIP, +/-0.05mm/QFP[when using Yamaha's standard components]

Mounting cycle time

0.18sec/CHIP, 1.7sec/QFP[under optimum conditions], 1608CHIP: 16,200CPH (0.22sec/chip)[IPC9850 condition]

Components applicable for mounting

0603~·31mm components, SOP·SOJ, QFP, connector, PLCC, CSP·BGA

FNC head: Allowable height on PCB surface before transport : 4mm max

Height of components which can be mounted: 15mm

Mounting of components with a height of 6.5 to 15mm is possible if certain conditions are met

Standard head: Allowable height on PCB surface before transport : 6.5mm max.

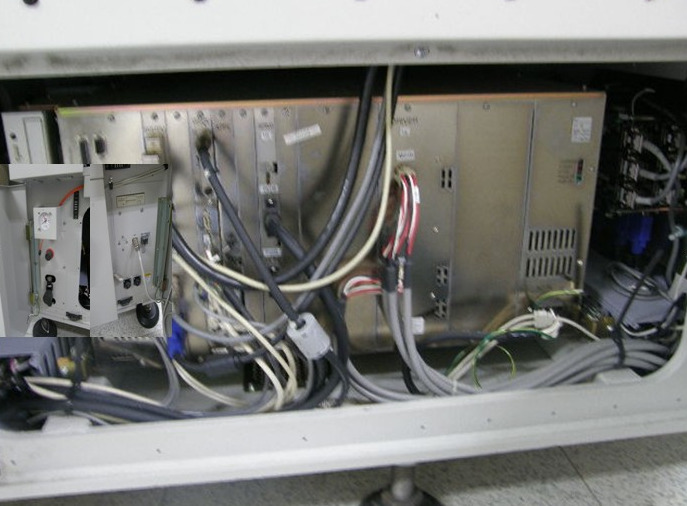

YAMAHA YV-100 XG is a revolutionary printed circuit board (PCB) assembly and manufacturing equipment. It combines precision engineering, fast and reliable processes, extended product lifespan, and state-of-the-art technology for the most advanced and efficient PCB production systems on the market today. YAMAHA YV100XG is designed for multiple PCB production and rework challenges, including automated handling of various types of circuit boards, from single sided and double sided to multilayer printed circuit boards. YV-100XG also allows for the installation of components with up to four leads, offering flexibility along with maximum efficiency. This advanced production system includes a four-axis rotary transfer unit, an advanced vision machine, and an integrated software platform. The four-axis rotary transfer tool is designed to handle flex and rigid flexible printed circuit boards, and allows for a high-speed robotic arm assembly. The integrated vision asset automatically inspects and reworks components, allowing for a reduced solder bridging probability. The integrated software platform offers a suite of tools coupled with model optimization techniques, ensuring maximum efficiency and flexibility. On top of that, the equipment comes with a range of testing and report generation solutions such as a read-only diagnostic board tester, a real-time production monitoring, and tracking system. YV-100 XG has won numerous awards for its advanced control and precision engineering, as well as its reliability and cost efficiency. It also meets IPC-A-610F standards and has been certified by JQA-QE08110A. YV100XG is the perfect choice for those who require a fast and reliable unit that produces high-quality, low-cost circuit boards.

There are no reviews yet