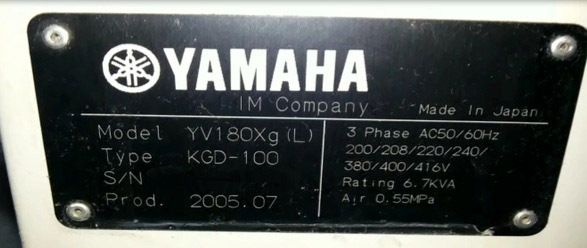

Used YAMAHA YV-180 Xg #9071648 for sale

URL successfully copied!

Tap to zoom

ID: 9071648

Vintage: 2005

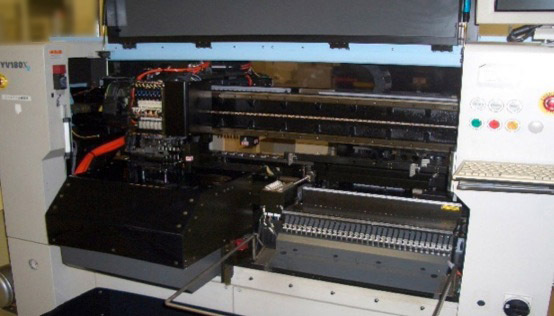

Chip mounter

Left to Right

Front fixed

Panel size: L Type: Max L380 x W330 mm ∼ Min L50 x W50 mm

Panel thick: 0.4 ~ 3.0 mm

Mounting: ±0.05 mm (0.01mm control)

Mounting angle: ±180° (0.01° control)

Mounting speed: 0.095 sec/chip

Feeder: max 80kinds (based on 8mm tape feeder)

Feeder size: 8mm - 56mm width tape, stick , bulk

Panel: 0603 - .25mm CSP, BGA, QFP, 100mm Connector

PCB height: max 6.5mm

Power: 3 phase, AC 200V ∼ 416V ±10%, 50/60Hz

Consumption: max 5KVA

2005 vintage.

YAMAHA YV-180 Xg PC Board assembly and manufacturing equipment is a semi-automated machine that is designed for use in medium to high-volume production environments. It features an automated component pick and place station that is capable of placing both surface mount and through hole components onto a printed circuit board. With its powerful servo motors and advanced vision system, it can accurately place components using a variety of techniques. YV-180 Xg also features a high speed solder paste dispensing unit that is capable of accurately and consistently applying solder paste to the PCB. Additionally, the machine has a fully automated spray fluxer that is designed to uniformly apply flux to the PCB prior to soldering. YAMAHA YV-180 Xg is a highly efficient tool capable of handling both single- and double-sided PCBs as well as BGA, CSP, and SMT components. Its high-speed belt conveyor enables products to go through the entire process quickly and smoothly, allowing for quick and easy assembly. The asset also features an advanced vision model that can detect and identify components as well as verify their placement for quality control purposes. It has a software-controlled component recognition equipment that can detect, recognize and record component attributes, such as part numbers and values that are then used to verify the accuracy of assembly. YV-180 Xg also has a library of foolproofing rules that can be used to ensure accurate and reliable assembly and reduce potential for component misplacement. YAMAHA YV-180 Xg is supplied with a Xg BoardMaster II software program that can create and save program setup data, as well as create job management programs that can control the entire assembly process. The software also has diagnostic and adjustment functions that allow users to easily troubleshoot and optimize assembly settings for maximum efficiency. YV-180 Xg system is robust, highly efficient and reliable, providing a cost-effective solution for high-volume PCB assembly and manufacturing. It is designed to optimize production efficiency and standards, while helping to reduce production costs.

There are no reviews yet