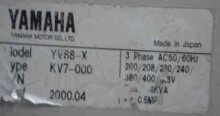

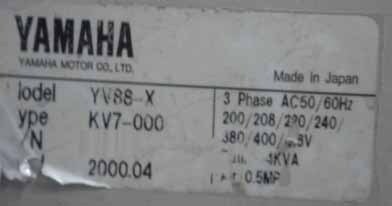

Used YAMAHA YV-88 X #9067867 for sale

URL successfully copied!

Tap to zoom

YAMAHA YV-88 X is a PC board assembly and manufacturing equipment that offers excellent performance and value. The system provides a comprehensive range of tools and features, allowing for complete and accurate assembly and manufacture of high-quality printed circuit boards (PCBs). YAMAHA YV88X utilizes a high-speed component placement unit that quickly and accurately places discrete components onto the PCB. The machine can place components with an accuracy of 0.0012" and a rate of up to 8,000 components per hour. It also has the ability to place high density components such as BGAs, QFPs, and 0201s. YV-88X tool is also equipped with an advanced laser vision asset that performs precision alignment and calibrates components to ensure accuracy. The model also provides automated inspection and verification of components, eliminating the need for visual inspection. YV-88 X is equipped with a powerful soldering equipment that uses advanced hot-air soldering technology to solder components onto the PCB. This system offers an accuracy of 0.001" and a rate of up to 4,500 solder joints per hour. It also performs reworking for failed components in order to reduce board waste. The unit also provides a robust material handling machine, allowing for quick and easy replacement of components. YAMAHA YV-88X is completely automated and controlled by YAMAHA PC Board Design and Production software suite. This software provides intuitive, easy to use tools for setting up and controlling the tool. Overall, YV88X offers high speed accuracy and quickly and precisely assembles and manufactures high-quality PCBs. The asset is user friendly and easy to set up and control. It provides excellent performance and value and is ideal for any manufacturer looking for a reliable and cost-effective solution for board assembly and manufacturing.

There are no reviews yet