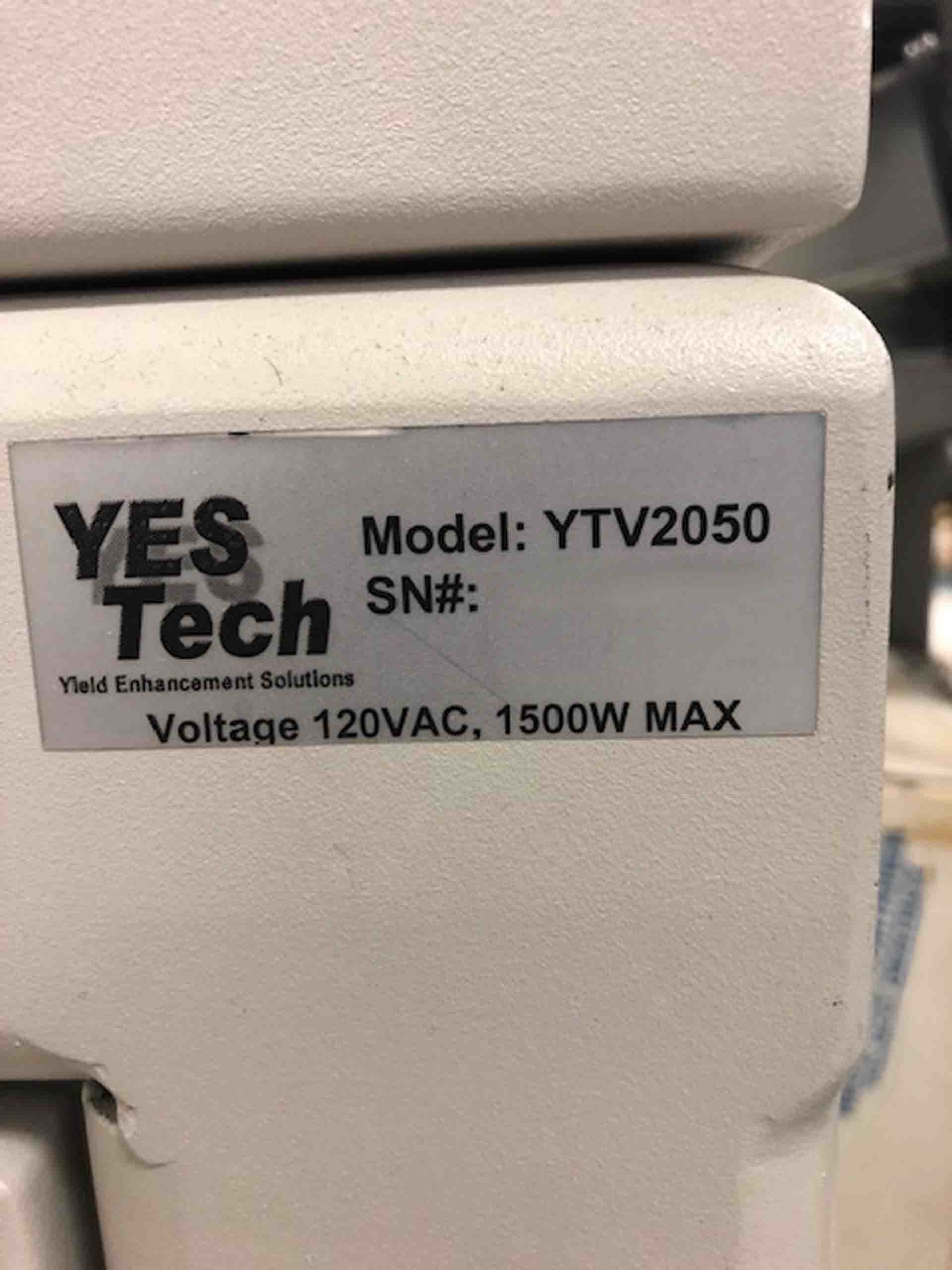

Used YESTECH YTV 2050 #9242393 for sale

URL successfully copied!

Tap to zoom

YESTECH YTV 2050 is an automated pc board assembly and manufacturing equipment designed for high volume production of printed circuit boards (PCBs). This system offers a ringless, rollerless handle transfer of boards with no impact on the PCBs. YESTECH YTV-2050 uses a two-sided mounter to accurately mount and pick up components to the top and bottom of the board with minimal deviation. The unit features intelligent vision, motion control and laser marking to create a high-quality assembly. The intelligent vision machine allows boards to be scanned accurately, detecting components and debug them in real time, while the motion control allows for a precise placement of components and a repeatable process that provides a high quality of assembly. Additionally, the tool's laser marking technology is able to quickly and accurately mark components on both sides of the board. YTV 2050 is a highly flexible machine that is easy to set up and easy to operate. It offers an expandable feeders with a variety of component shapes and sizes, different programmable mounting positions and an increased component range with high-precision placement. The high speed centering lift is designed to prevent board warpage and vibration when transferring, and thus ensuring enhanced handling accuracy. YTV-2050 has also been designed with energy efficiency in mind, using an advanced inverter control asset that decreases running costs, and a low noise and low vibration design for a more comfortable working environment. In addition, the model has comprehensive safety features such as protected operator controls and operator safety circuits, so any potential risks are minimized. In summary, YESTECH YTV 2050 is a robust, efficient and economical equipment for assembling and manufacturing printed circuit boards. It offers strength, speed, accuracy and precision, along with advanced vision and motion control, modular expandable feeders, laser marking technology and comprehensive safety features. This comprehensive system provides a reliable and reliable solution for PCB assembly and manufacturing requirements.

There are no reviews yet