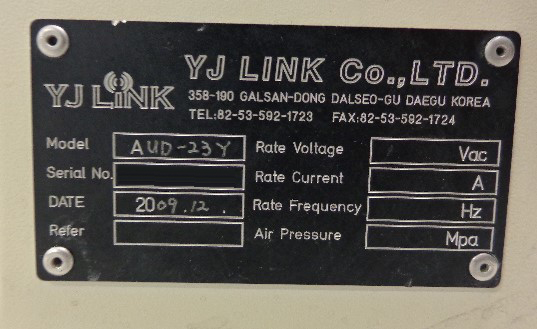

Used YJ LINK AUD- 23Y #9177397 for sale

URL successfully copied!

Tap to zoom

YJ LINK AUD- 23Y is a type of pc board assembly and manufacturing equipment used for the fabrication of printed circuit boards (PCBs). This system is typically a 4-in-1 machine consisting of a three-axis milling machine, a three-axis engraver, a three-axis inspection robot, and a three-axis pick-and-place machine. The combination of these four machines allows for the creation of both high-precision and high-production-rate PCBs. AUD- 23Y milling machine utilizes a three-axis unit for the cutting and engraving of the PCB shape and ready-made electronic components. The three axes of motion consist of a 1350mm traverse, a 1300mm lift, and a 1250mm swing. The spindle speed of the milling machine ranges from approximately 800 to 16,000rpm, allowing for a variety of cutting profiles for a variety of materials such as aluminum, copper and steel. The engraver of YJ LINK AUD- 23Y also operates in a three-axis machine. It is capable of engraving on a wide range of surfaces such as foil, metal and plastic. The engraver features a high-resolution camera that enables the tool to accurately reproduce designs up to a tolerance of μg (micrograms). The spindle speed of the engraver ranges from 1000 to 24,000rpm, allowing for a range of cutting profiles depending on the desired end-result. The inspection robot of AUD- 23Y guarantee quality assurance of the assembled PCBs by measuring and verifying the accuracy of all integrated components as well as checking for any flaws in the soldering process. Due to its high-resolution camera, the robot is capable of detecting defects in the soldering process that may be smaller than 1mm in width and depth. This ensures that all PCBs produced are of the highest quality. The pick-and-place machine of YJ LINK AUD- 23Y allows for the automatic insertion of the components used in the assembly of the PCBs. The machine is equipped with a high-speed vision asset that tracks and positions components in the right orientation before they are placed onto the PCB. The pick-and-place machine is capable of handling components of up to a maximum of 8x8mm in size and features a maximum speed of 7,000rpm. Overall, AUD- 23Y is a comprehensive model of machines that enable the fabrication and assembly of high-precision and high-quality PCBs in a cost-effective and time-efficient manner. The combination of four machines into one equipment allows for single-step production, resulting in greater accuracy, reduced costs and shorter leadtimes.

There are no reviews yet