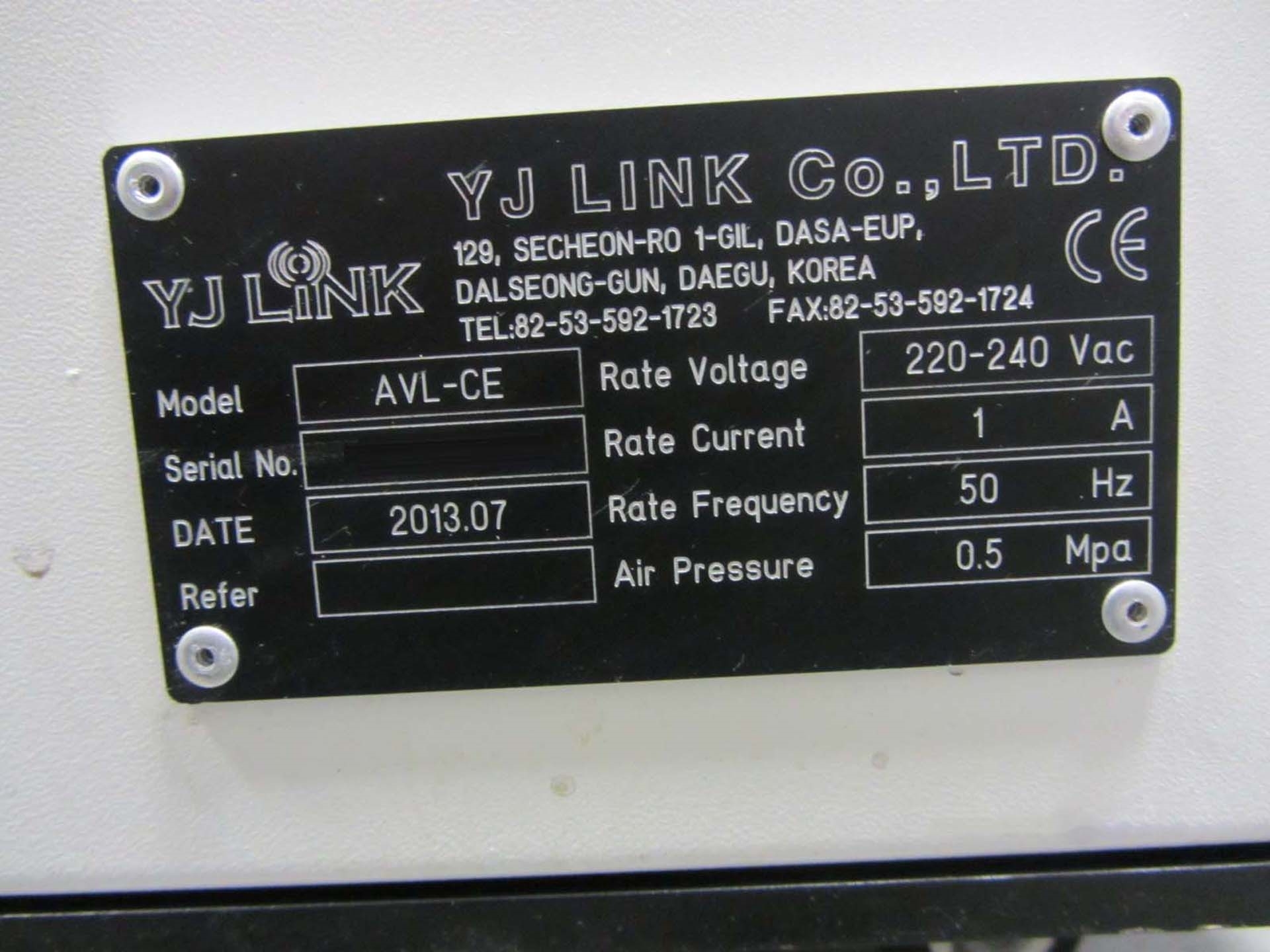

Used YJ LINK AVL-CE #9267631 for sale

URL successfully copied!

Tap to zoom

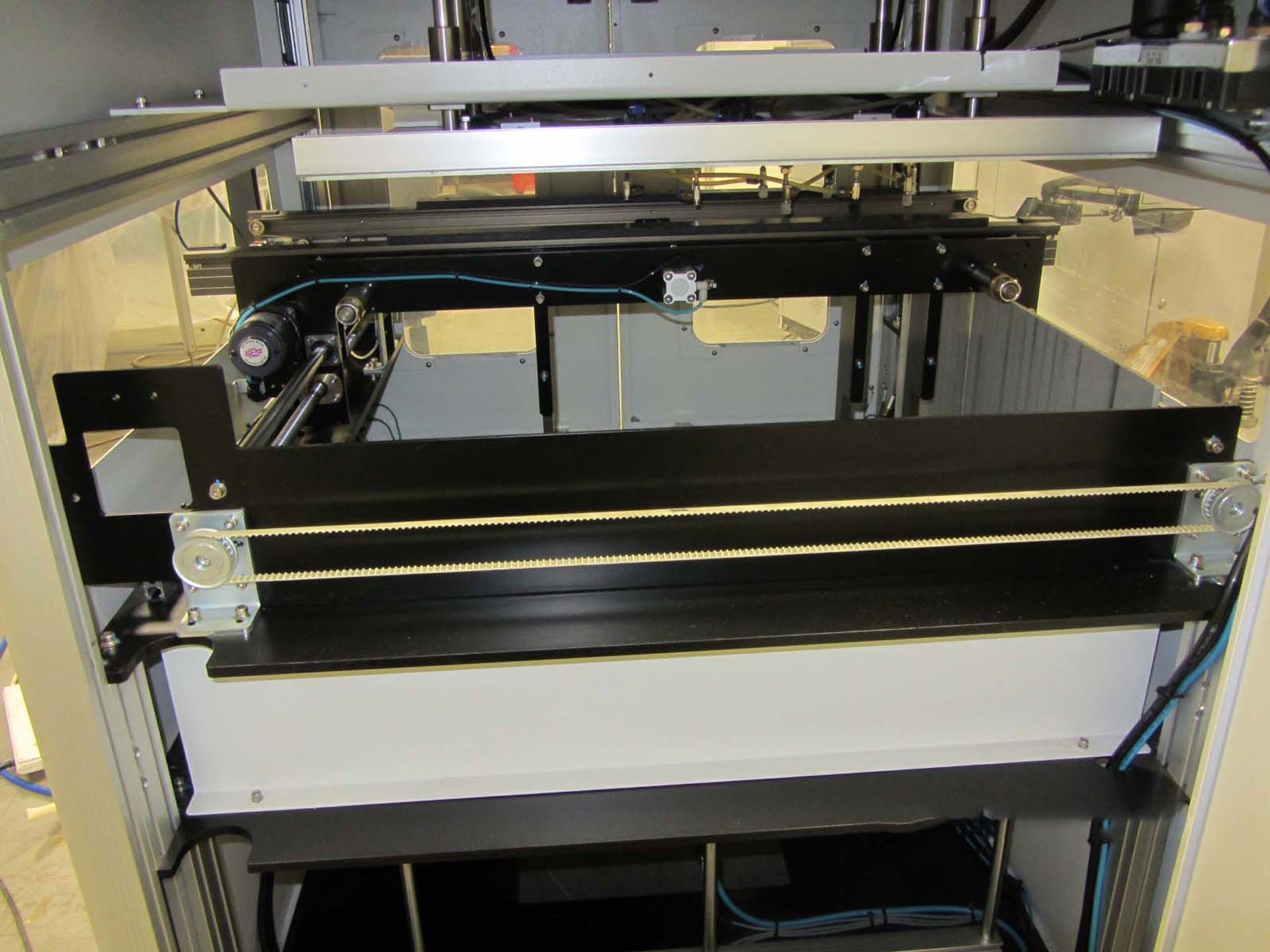

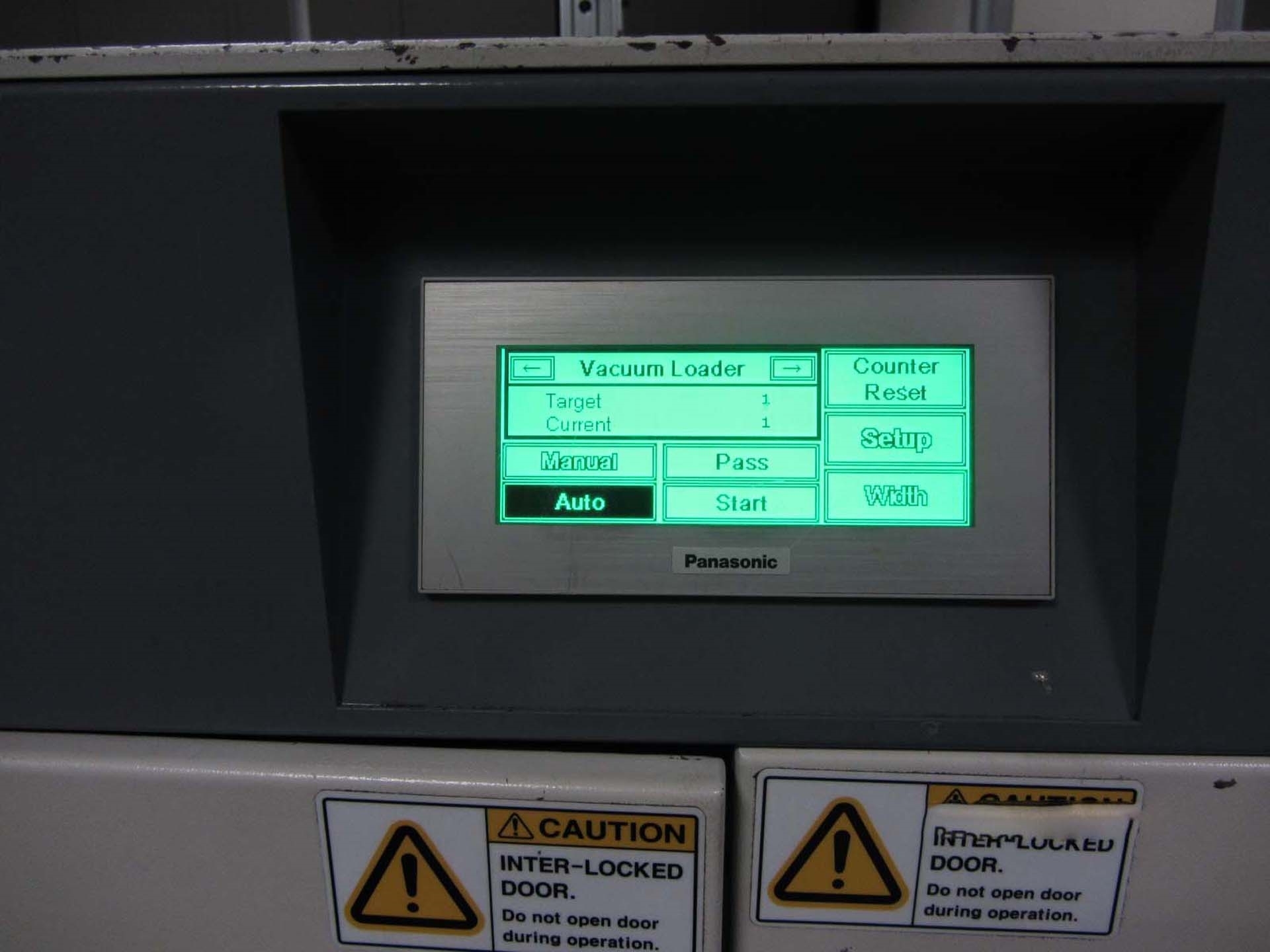

YJ LINK AVL-CE is a pc board assembly and manufacturing equipment that uses advanced technology to ensure the highest quality results in the production of electronic components and printed circuit boards. The system automates the assembly process with its integrated digital machinery and material handling hardware. The unit has a standardized process for material loading, circuit board cleaning and circuit board assembly. The platform is integrated with YJ LINK Automated Component Identification (ACI) and Industry 4.0 software, allowing it to identify parts fast and accurately in order to quickly lay them down for soldering. The machine is equipped with an automatic solder printer to print solder paste accurately and consistently on the prepared substrate. The laser tweezer, which is integrated with the tool, provides accuracy in component placement and assembly. The asset also provides the flexibility to use custom job programming and molding settings. Moreover, it enables real-time shot time data collection for analysis of components and production line operations. Moreover,high-precision automation is possible with AVL-CE model's two-dimensional Programmable Deflection Equipment (PDF) which is integrated with high speed commands and an XYZ-axes movement. This gives a great degree of accuracy while controlling the motion of the robotic arm. With its integrated 3D vision technology, the system can recognize and pick up components with great precision and accuracy. The unit also has an air pre-heater machine, which is integrated with the assembly platform, to get the best results in solder paste dispensing. The tool also has an integrated power safe distribution asset and an in-line stress testing process to test each component and ensure top quality results. Overall, YJ LINK AVL-CE is a highly advanced and productive pc board assembly and manufacturing model, equipped with advanced technology and features to automate the manufacturing process. It provides higher levels of accuracy and precision, as well as automated production line operations with real-time data analysis. Its integrated ACI and Industry 4.0 software ensures component identification and placement, while its air pre-heater equipment and power safe distribution system ensure safety while producing top quality results.

There are no reviews yet