Used ZEVATECH / JUKI 2080M #9107988 for sale

URL successfully copied!

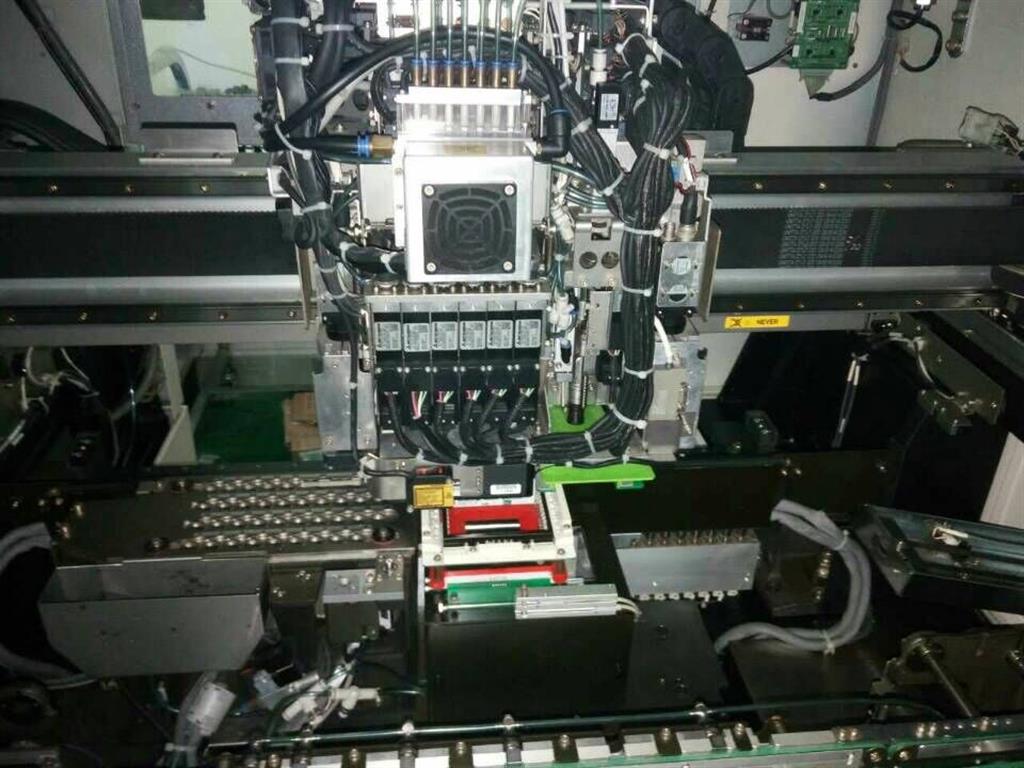

Tap to zoom

ZEVATECH / JUKI 2080M PC Board Assembly and Manufacturing equipment is a high-end automated soldering and soldering detection system used in the production of printed circuit boards (PCBs). It is suitable for a variety of applications, including mass production of small, medium and large volume electronics products. JUKI 2080M unit features a high-speed X, Y and Theta axis motion driven by a high-torque servo motor, allowing for fast and precise motion control. The machine also features a powerful mandrel pick-and-place head and twin-head soldering tool, which offers dual-axis soldering heads for precision soldering of up to ten nozzles. The nozzle tips are connected to a servo motor connected to a peripheral i-Pulse controller under control of a PC interfaced with a library of common components. ZEVATECH 2080M asset also features automated optical inspection and soldering detection technology. A three-camera model is used for board inspections, along with fiducial mark recognition and software tracking. This ensures correct board placement and accuracy, and enables automated soldering detection using visible red light laser signals. The soldering process is further enhanced by an onboard fluxer supply equipment, which supplies pre-determined amounts of flux to the soldering surface. This helps to ensure reliable and accurate soldering and prevents shorting and bridging due to flux overflow. 2080M system also features an easy-to-use operator console interface that allows for the selection of commonly used operations, including solder joint placement, inspection, soldering, and cleaning cycles. This ensures that the most common operations are quickly and easily accessible, and helps to reduce production time. ZEVATECH / JUKI 2080M unit also features built-in safety features, such as emergency stop buttons and detected motion sensors. This ensures that the machine operates safely and efficiently, and that personnel and equipment are kept safe at all times. In conclusion, JUKI 2080M PC Board Assembly and Manufacturing tool is a high-end automated soldering and soldering detection asset suitable for a variety of PCB manufacturing applications. It features a high-speed X, Y and Theta axis motion, twin-head soldering, automated optical inspection, and an onboard fluxer supply model. It also has an easy-to-use operator console interface and built-in safety features. This equipment is a reliable and efficient solution for PCB manufacturing.

There are no reviews yet