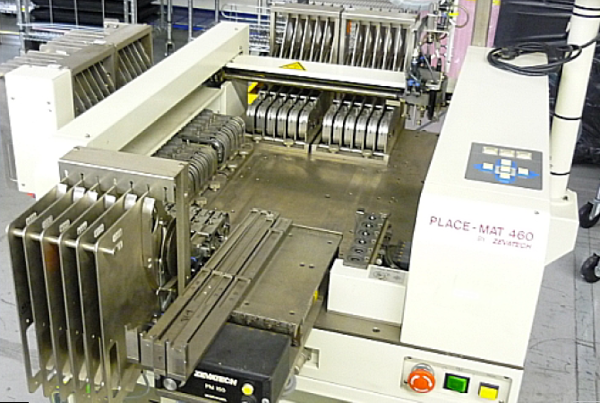

Used ZEVATECH / JUKI 460 #191288 for sale

URL successfully copied!

Tap to zoom

ID: 191288

Pick and place machine

OS: MS-DOS

V/Hz: 100 VAC 50/60Hz

VA: 8.00

P: 600 W

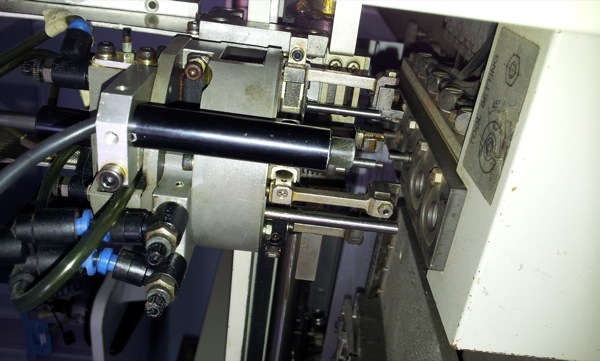

Nozzle alignment block

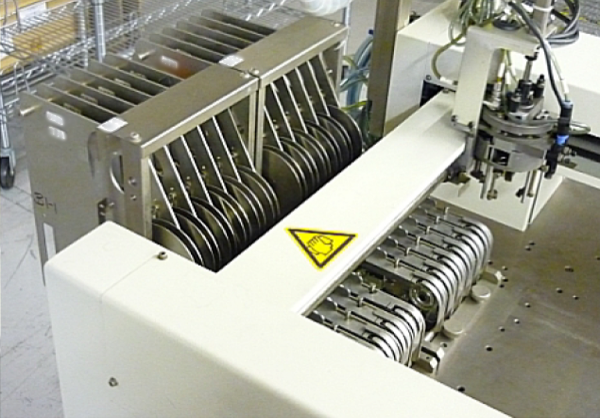

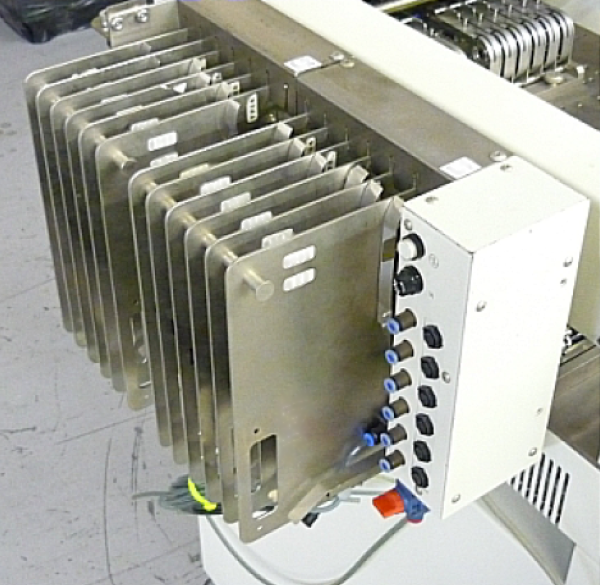

(34) 8mm feeders

(1) 12mm feeder

(1) 16/24mm feeder

Vibratory with (4) rails: (3) SOIC8 and (1) SOIC14

Manual

~1993 vintage.

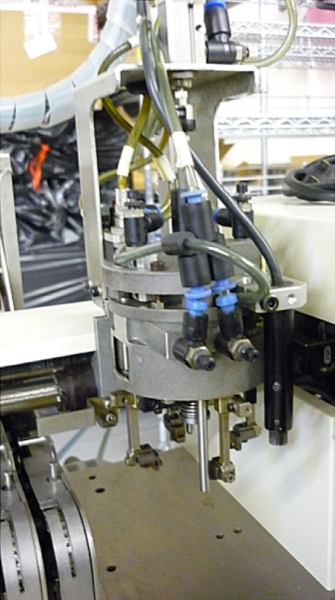

ZEVATECH / JUKI 460 is an advanced PC board assembly and manufacturing equipment designed to meet the needs of modern electronics assembly. This high-end pick-and-place system features a range of advanced automation and production technology, making it suitable for quick, efficient assembly of even the most complex PCBs. The unit is equipped with a streamlined design for maximum user convenience. It comes with a high-resolution camera, plus a set of special light guides ensuring excellent visibility for accurate placement and inspection. JUKI 460 also includes intuitive touchscreen-controls, enabling users to easily manage the layout pattern, speed, and precision of each PCB assembly project. Additionally, the machine is powered by a powerful onboard computer and features a number of built-in software packages for monitoring production rates, keeping track of assembly batches, and linking into external CMMs and other automated products. The heart of the tool is its advanced, high-speed automated pick-and-place head, capable of rapid movement with minimal impact on production results. The asset is also designed to handle a wide range of components and pick-and-place motions, including simple-to-complex board assemblies. Its high-powered nozzles, feeders, and component trays can accommodate a wide variety of components. Additionally, ZEVATECH 460's high-resolution camera and video sensors can detect components of any form and thickness, while its flexible motion control enables the fast placement of components up to 25mm diameter. Further, the model is equipped with advanced onboard algorithms to help operators maximize precision and speed. These features enable 460 to achieve an impressive cycle time of less than 10 seconds for each component layout. Additionally, the equipment is designed to offer the best possible thermal performance, and users can easily monitor temperature and other variables related to proper PCB assembly with its built-in thermal sensors. ZEVATECH / JUKI 460 also offers cost-savings with its low maintenance design plus improved usability of components. The system performs a thorough self-diagnosis to help ensure smooth and safe operation. In conclusion, JUKI 460 is an advanced, highly automated pick-and-place machine designed to make the assembly of complex PCBs simpler and faster. With its intuitive user controls and reliable performance, this unit is ideal for meeting the challenges of today's electronics assembly.

There are no reviews yet