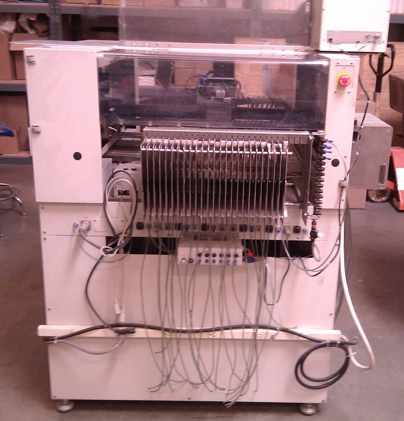

Used ZEVATECH / JUKI 560 #153801 for sale

URL successfully copied!

Tap to zoom

ID: 153801

Pick & place machines

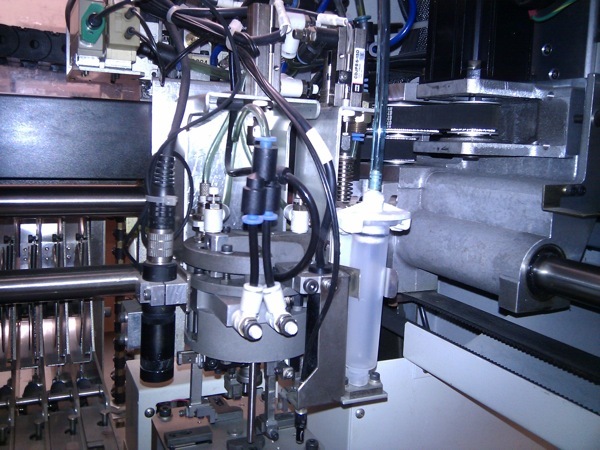

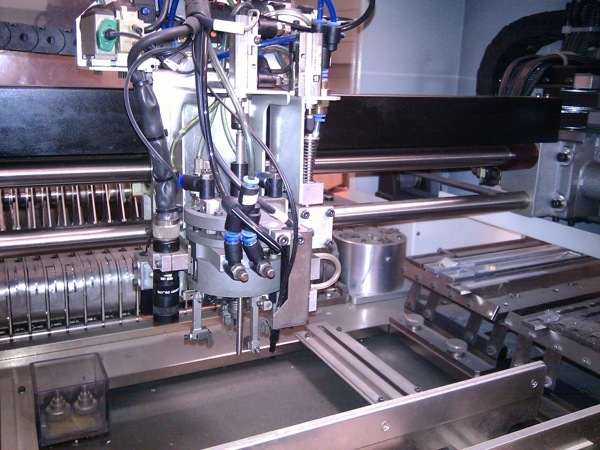

Vision capability

Teach cameras

Includes:

Motors

(~100) Feeders:

8 mm

12 mm

Vibratory.

ZEVATECH / JUKI 560 is a high-speed pc board assembly and manufacturing equipment that is designed to enhance the efficiency and productivity of various production lines. It offers the latest in modern technology along with the flexibility to meet custom production lines. This robust system offers the highest level of automation available with features such as inspection, test and verification, as well as vast operational components such as fluxing, scrapping, gluing, press-fitting, soldering and more. The unit also integrates well with other systems, as well as existing personal computer technology used in most production lines. The machine utilizes powerful components for faster throughput and maximum productivity such as the Process Control Module that supports up to 32 processes and two sets of program files along with an optional User Interface Module that supports user-defined processes. Other components of the tool include an illustrated Manual Teach Mode the one touch adjustment. This asset is designed to operate both in the factory and enterprise level. With its advanced control model, JUKI 560 is designed for real-time monitoring of all process parameters. In addition to providing faster task execution, the equipment also offers a higher level of capability in process repeatability and accuracy. This is due to the inclusion of components such as micro-step resolution and process review, which measure and record the level of production to help identify areas of need or improvement. ZEVATECH 560 also features various programming languages which enable the flexibility of custom applications and application development. Through these languages, the system can control all aspects of the production line, and allow users to modify the unit based on their needs. It also offers a complete range of data flow control, communications and storage features, allowing complete control and traceability of the production process. 560 has become a reliable and leading solution for pc board assembly and manufacturing due to its high level of flexibility, machine integration, and advanced feature set. Its robust construction ensures a high level of reliability, as well as its advanced programming and data flow control capabilities, resulting in increased safety and quality assurance. With its comprehensive range of features, users can benefit from the tool's ability to meet their specific needs and desired outcomes.

There are no reviews yet