Used ZEVATECH / JUKI 740 #9159085 for sale

URL successfully copied!

Tap to zoom

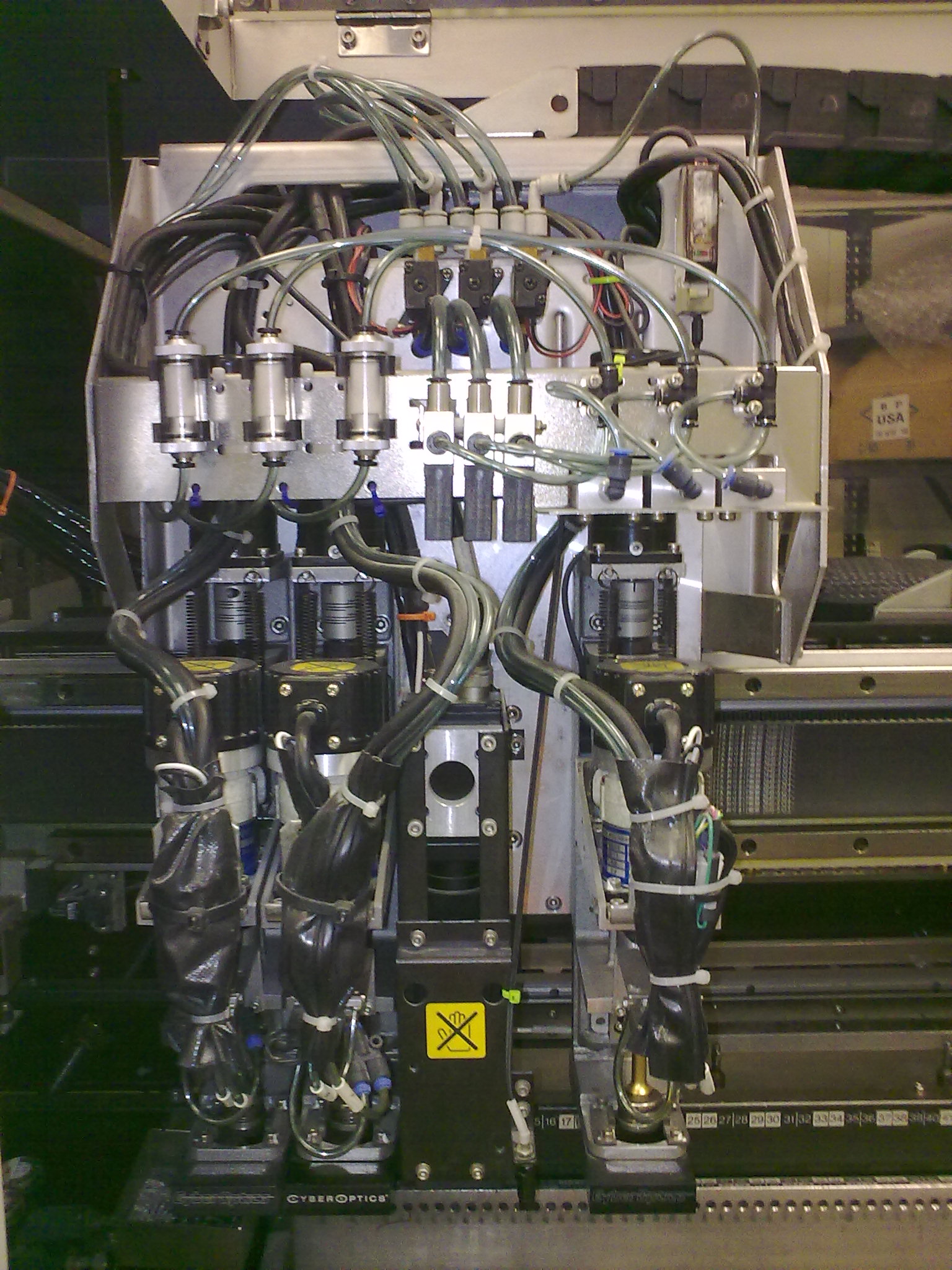

ZEVATECH / JUKI 740, also known as the EPF7500 is a advanced PC Board Assembly and Manufacturing Equipment. JUKI 740 is designed with a highly efficient modular configuration that allows it to be quickly adapted to meet the needs of any manufacturing process. ZEVATECH 740 is equipped with a powerful tool library that includes various sorting systems, vibration sorters, and electromechanical components. It also utilizes a precision spindle mechanism with an adjustable pressure loading system that offers high repeatability. 740 also comes with the flexibility to transition between processes quickly and quickly achieve the desired product quality and repeatability even in complex manufacturing environments. The unit is capable of handling a wide range of board types, ranging from conventional rigid boards to flex and high-density interconnect solutions. ZEVATECH / JUKI 740's high-speed vision machine is capable of capturing images of entire PCBs in a fraction of a second, greatly improving accuracy and decreased production time. It is also able to load pins in a fraction of a second, enabling faster troubleshooting and increase in throughput. The EPF7500 supports various kinds of programming languages designed to support board testing and process optimization. It is also integrated with multiple I/O interfaces such as, radiofrequency identification (RFID). It also supports integration with various communication protocols including WLAN, Ethernet, and USB2. JUKI 740 has a revolutionary semiconductor placing head that enables high-speed placement of all types of components, including BGA, CSP, QFP, uBGA, aLGA, and SMT. ZEVATECH 740 further enables precise placement by using X-axis translation for fine adjustability and Y-axis rotation for better precision. 740 offers standard features like autoloader shutdown, board detection and collation, and remote alarm reset. Through its integration with JUKI Quality Control Tool (QCS), ZEVATECH / JUKI 740 is able to detect and respond to failures and other process irregularities. This provides users with real-time feedback and alerts pertaining to the problem, allowing high quality product output. Overall, JUKI 740 EPF7500 is a robust and reliable asset for board assembly and manufacturing that can offer production accuracy and efficiency. It has been designed with a variety of features that make it suitable for use in any industry. Its highly efficient tool library, advanced vision model, and integrated communication protocols make the EPF7500 one of the most sought-after systems today.

There are no reviews yet