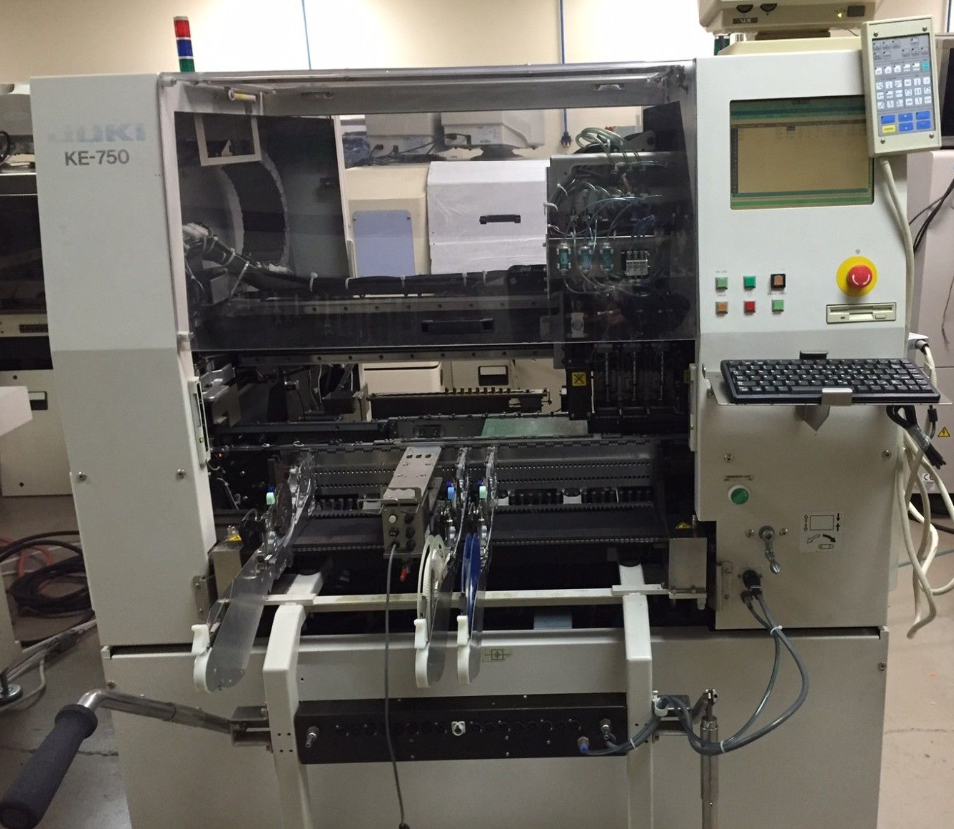

Used ZEVATECH / JUKI 750 #9081176 for sale

URL successfully copied!

Tap to zoom

ID: 9081176

Pick and place system

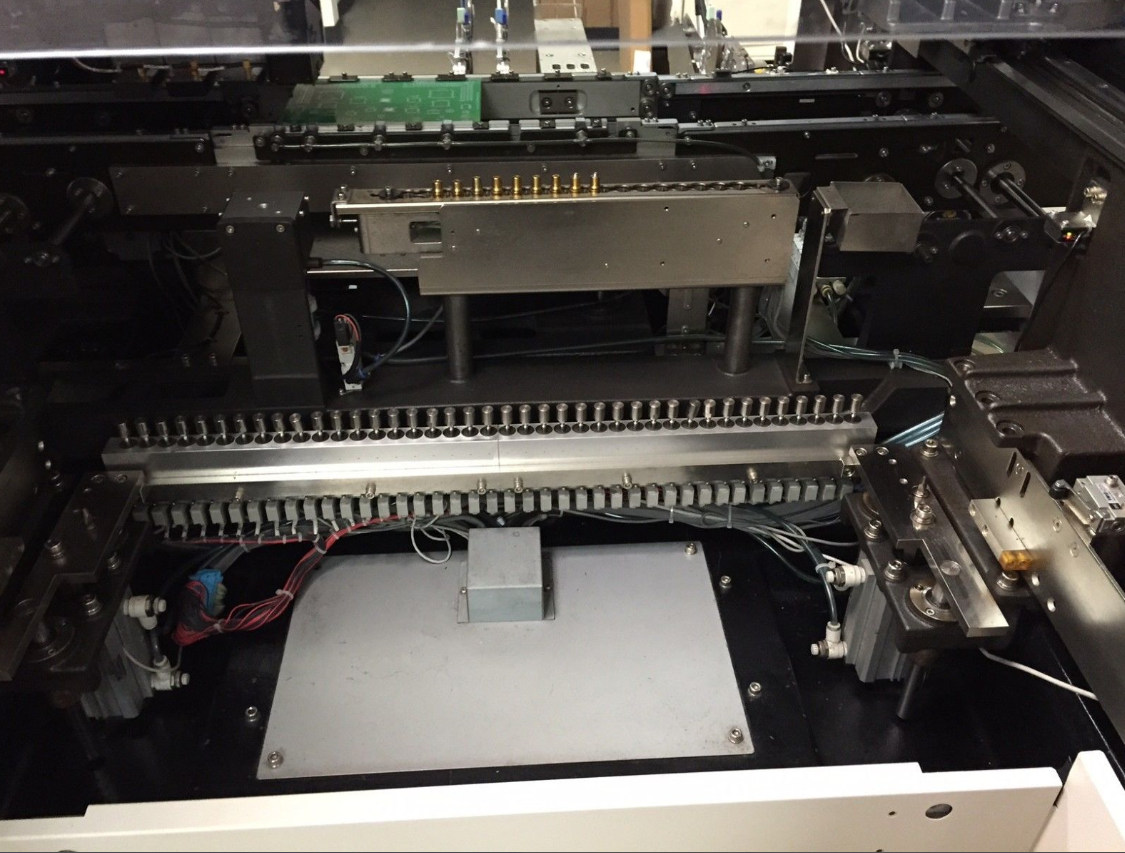

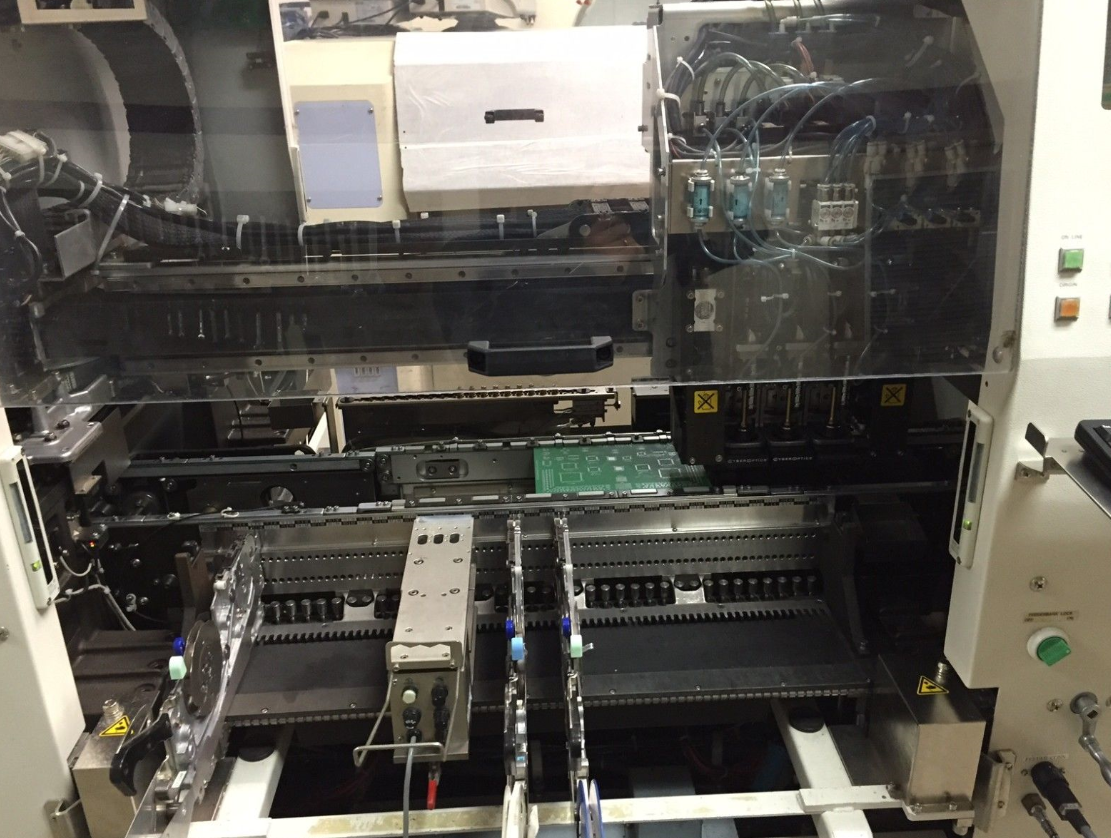

(3) Heads

(2) Trolleys: Front and rear

Feeder float detection

Rated at 11k CPH

Parts down to 0201

Manuals and software included

(10) feeders included

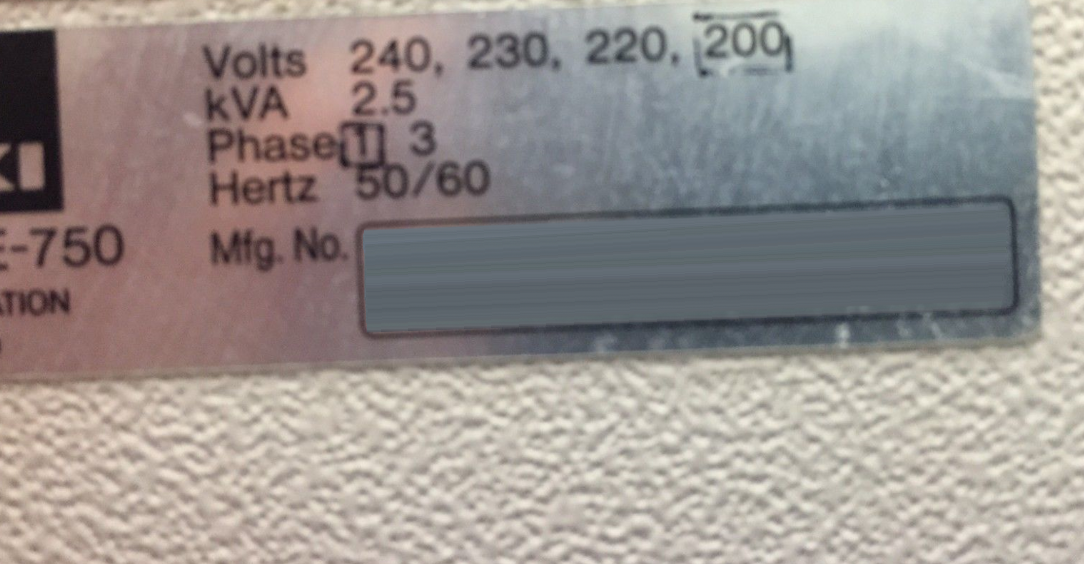

200 V, 1 Ph, 50/60 Hz, 2.5 kVA.

ZEVATECH / JUKI 750 is a next-generation SMT platform for printed circuit board (PCB) assembly and manufacturing. It is designed to meet today's advanced requirements for manufacturing high-end electronic products. The equipment utilizes high-speed, programmable direct drive technology to accurately place components onto the board with pick rates of up to 16,000 components/hour. JUKI 750 features an ultra-low-profile feeder base, with a manual/automatic gantry system for easy loading/unloading and for easy transitions between PCBs and feeder trays. The unit has a built-in board indexer for creating the optimum feeder track to achieve the desired placement accuracy and speed. The machine is designed with advanced vision technology to inspect each component that is placed onto the board. It also has automatic pin-in-paste (IPI) capability to simplify the programming process. The tool supports a wide range of components and boards, including 0402, 0.5mm, 1.0mm, ultra-fine-pitch, nonstandard and multilayer boards, as well as paste slitters and single and multiuse combination dispenses. ZEVATECH 750 has expandable capacity and a low capital outlay, making it ideal for PCB assembly and manufacturing. The asset's process control software delivers high-speed, high-accuracy placement results, along with advanced error-detection features. The software supports fully integrated setup and programming for all components, assurance of fiducial misalignment before and after reflow, and adjustable layer heights for multi-layer boards. Its embedded simulation software helps to ensure error-free product programming, programming of intelligent and adaptive systems, consistency of board results, automated process control and post-process evaluation of all placement information. 750's user-friendly control panel simplifies operator setup and control. It provides an intuitive, graphical user interface (GUI) to quickly and easily adjust machine parameters and programs. Other features, such as real-time product traceability and a built-in camera viewer, make ZEVATECH / JUKI 750 an ideal solution for high-precision PCB assembly and manufacturing.

There are no reviews yet